Large ground photovoltaic power station assembly assembling and disassembling auxiliary equipment

A technology of ground photovoltaic power station and auxiliary equipment, applied in ladders, buildings, building structures, etc., can solve the problems of performance degradation, inconvenient operation, and falling of lower row components, and achieve the effect of improving loading and unloading efficiency, simple structure, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

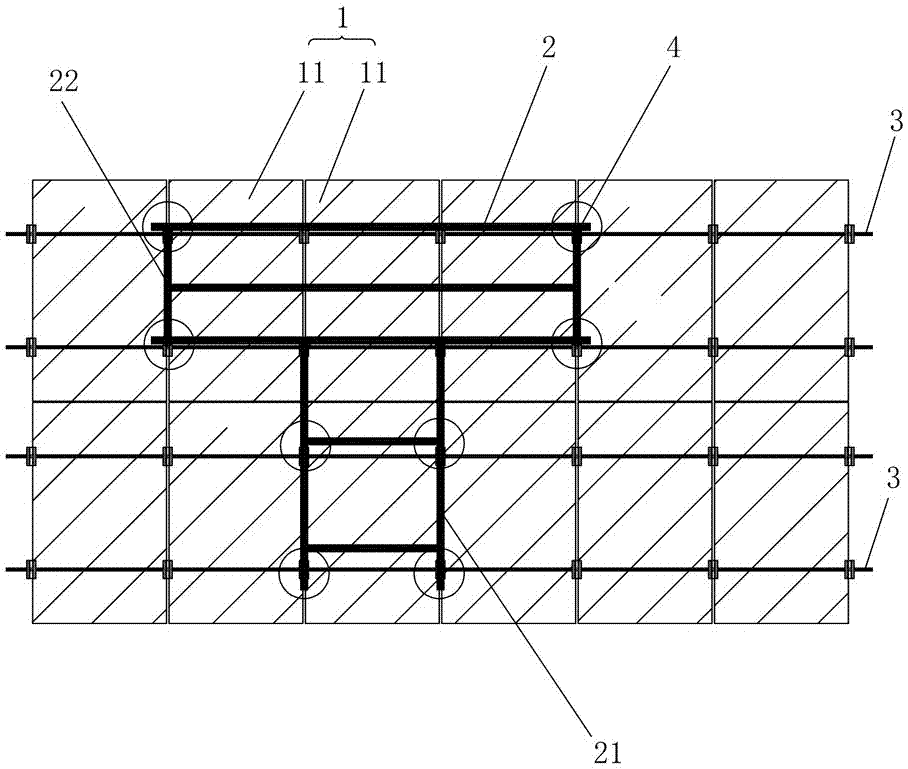

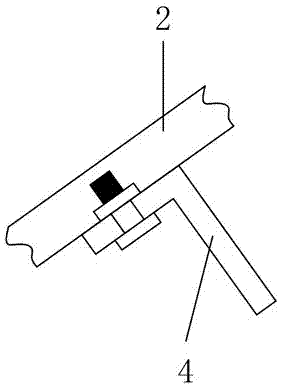

[0020] Such as figure 1 , figure 2 with image 3 As shown, the large-scale ground photovoltaic power station module loading and unloading auxiliary equipment in this embodiment, the large-scale ground photovoltaic power station module includes at least two rows of modules 1, each row of modules 1 includes a plurality of module units 11 arranged at intervals, and the loading and unloading auxiliary equipment includes ladders 2, Four horizontal guide rails 3 and eight buckles 4 (corresponding to figure 1 Each circular area in the center), four horizontal guide rails 3 are arranged at intervals along the vertical direction, each horizontal guide rail 3 is fixedly connected to the component 1 and its end extends to the outside of the component 1, eight buckles 4 are detachably connected to the ladder 2 On the left and right sides, each buckle 4 is clamped between two adjacent left and right component units 11 , and the horizontal guide rail 3 is supported under the buckle 4 . ...

Embodiment 2

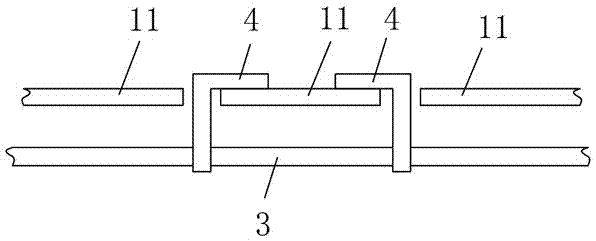

[0025] Such as Figure 4 As shown, the auxiliary equipment for loading and unloading large-scale ground photovoltaic power plant components in this embodiment is basically the same as that in Embodiment 1. The two adjacent component units 11 are detachably connected to the ladder 2, the two sides of the T-shaped buckle are respectively placed on the back of the two adjacent component units 11 on the left and right, and the horizontal guide rail 3 is supported under the middle part of the T-shaped buckle . In this embodiment, the T-shaped buckle itself is a symmetrical structure. Compared with Reference Document 1, in addition to ensuring that the ladder 2 does not shift left and right to further improve reliability, there is no need to ensure that all buckles 4 are symmetrically installed on the ladder 2 The left and right sides simplify the installation process and make it more convenient to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com