A Comparative Automatic Rutting Tester

A rutting test, automatic technology, used in instruments, the use of repetitive force/pulse force to test the strength of materials, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

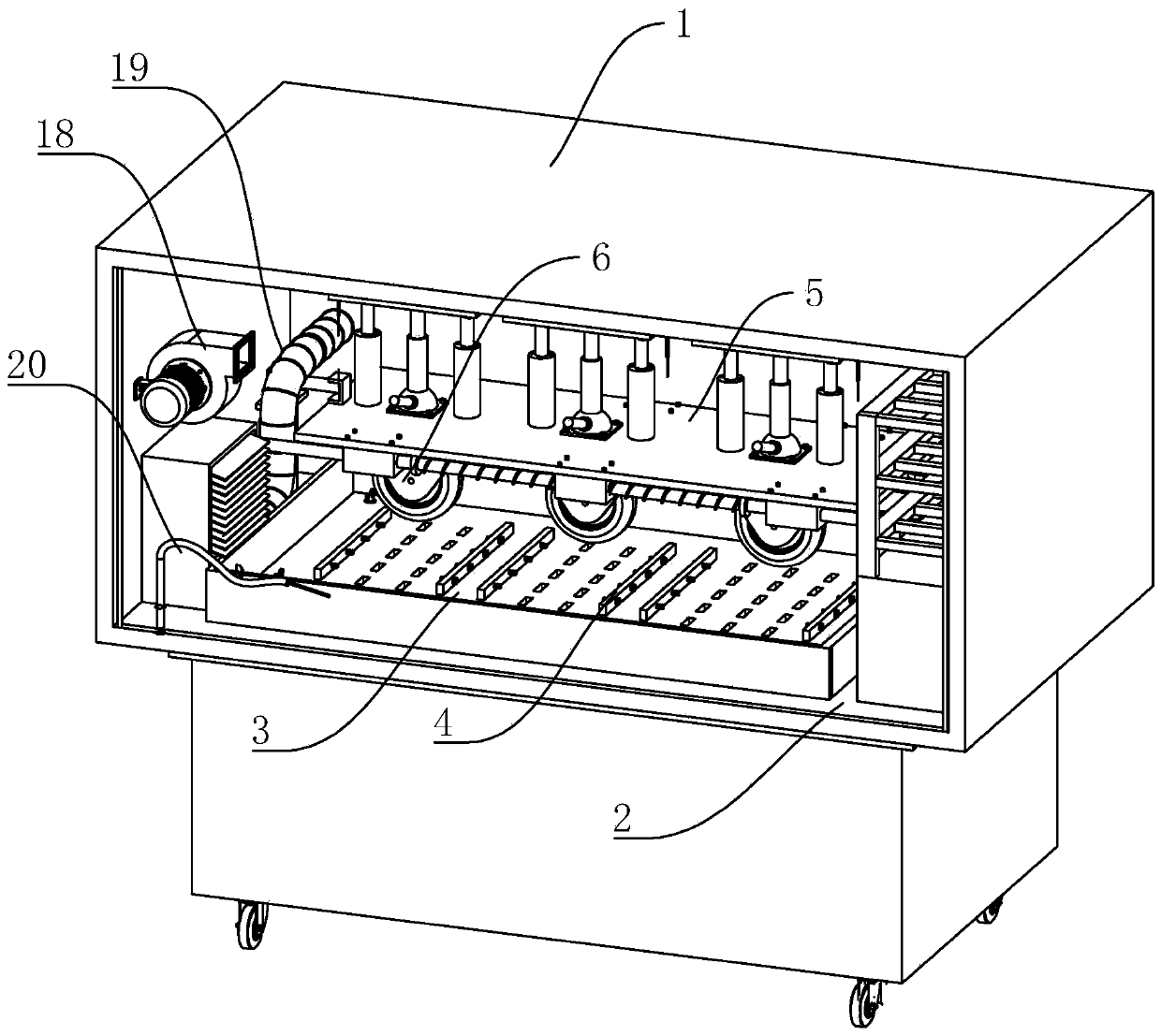

[0029] A comparative automatic rutting tester, refer to figure 1 , including a frame 1, a sliding door (hidden in the figure) is arranged on the inside and outside of the frame 1, and an installation platform 2 is arranged inside, and a storage platform 3 and a positioning plate 4 are arranged on the installation platform 2 for fixing concrete Test piece, at the same time, a driving device 5 is provided on one side of the installation platform 2 to drive the test vehicle 6 reciprocatingly installed on the top of the storage platform 3, and a supply fan 18 and an exhaust fan 19 are arranged on the other side of the installation platform 2 and a temperature sensor 20 for adjusting the temperature inside the rack 1 .

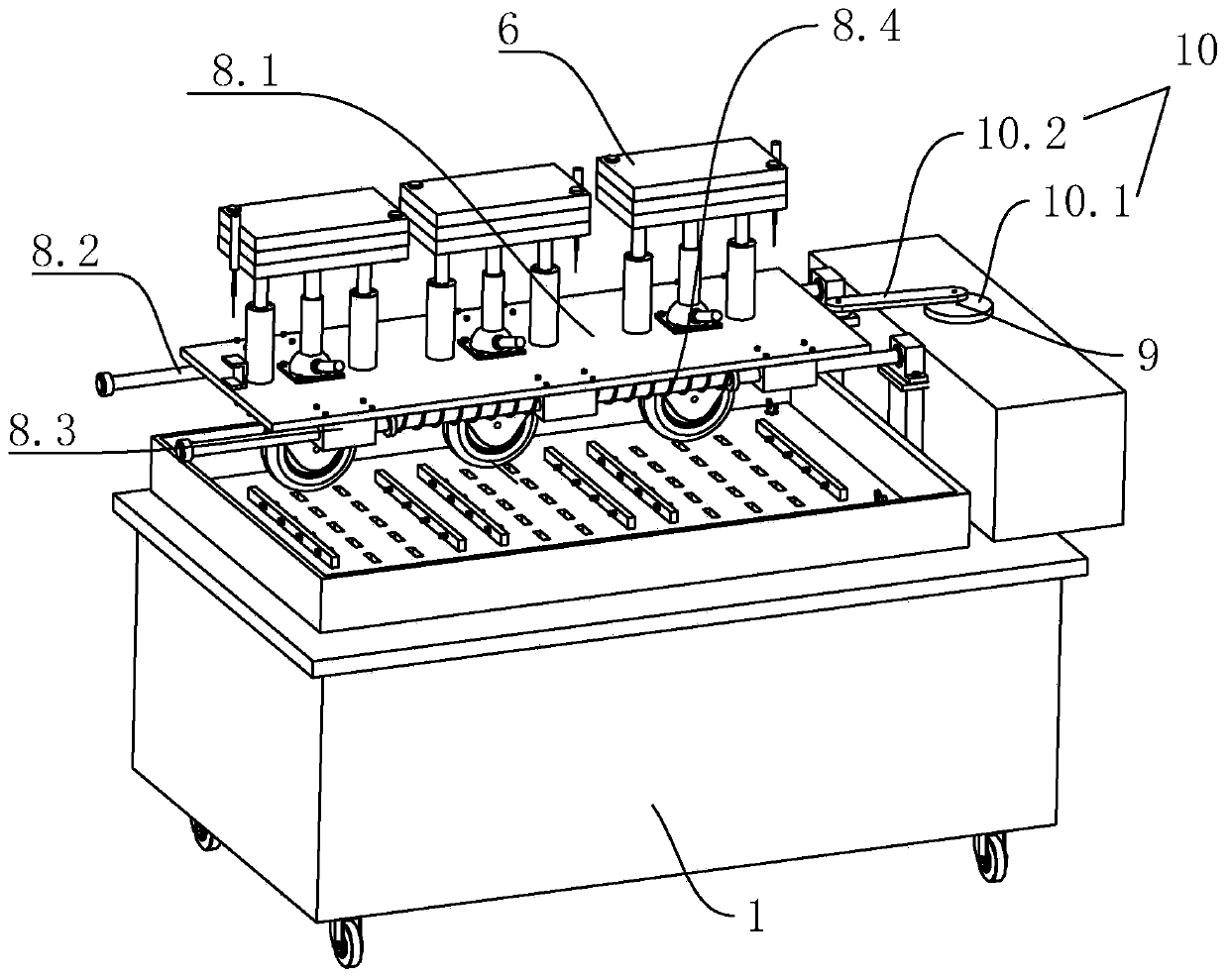

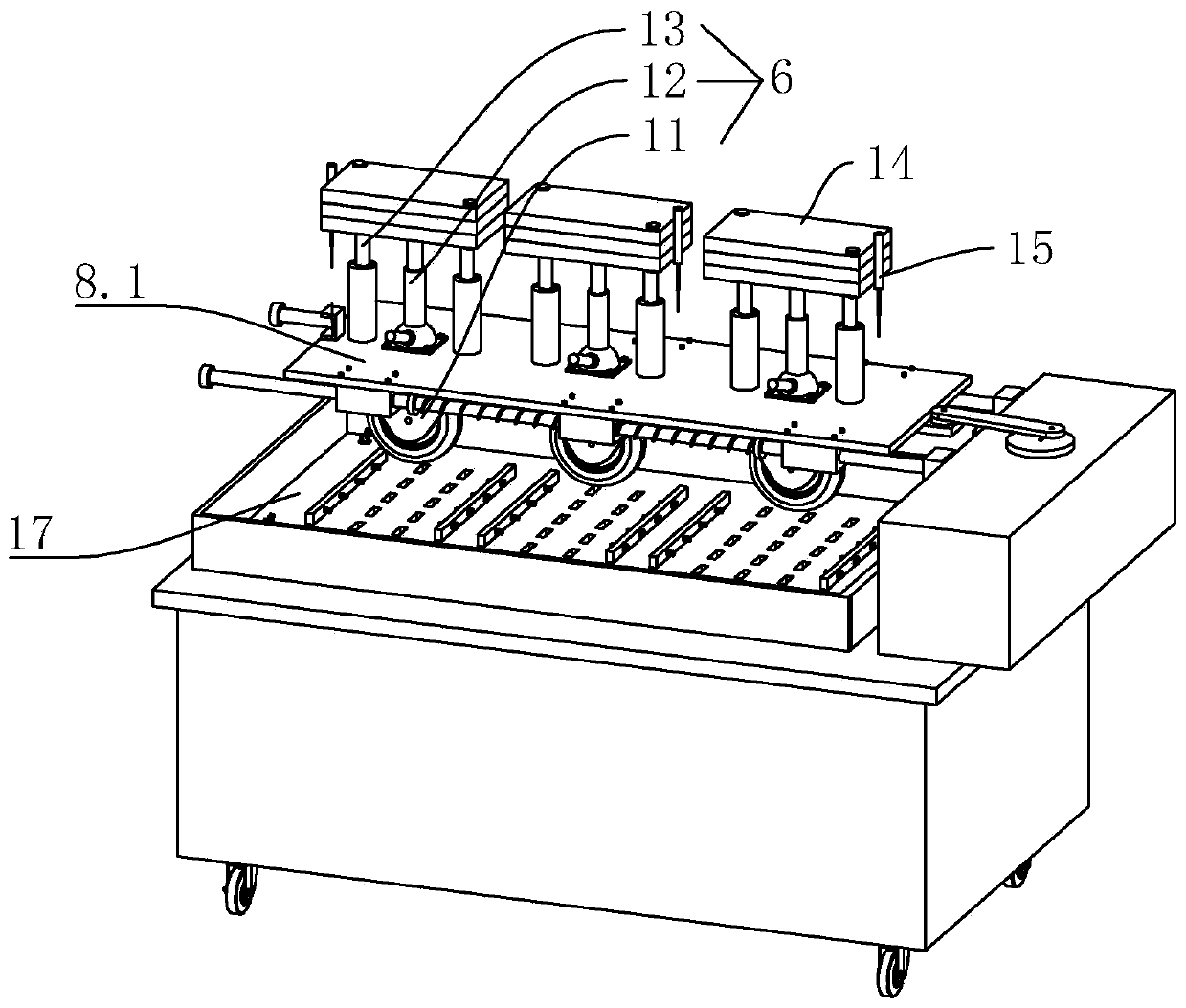

[0030] drive unit 5 reference figure 2 , including the installation plate 8 for installing the test vehicle 6, the installation plate 8 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com