Fried bread stick-machining efficient rolling cutting machine and using method thereof

A cutting machine, high-efficiency technology, applied in the direction of dough sheeting machine/rolling machine/rolling pin, application, dough forming and slitting combination, which can solve the problem of large time consumption, difficulty in holding the noodle roll, narrow noodle block width Different problems, to achieve the effect of uniform width, reduce operation intensity, and reduce time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

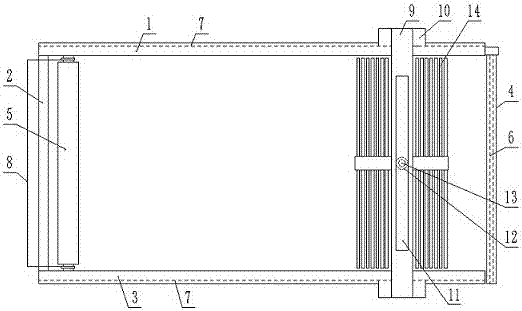

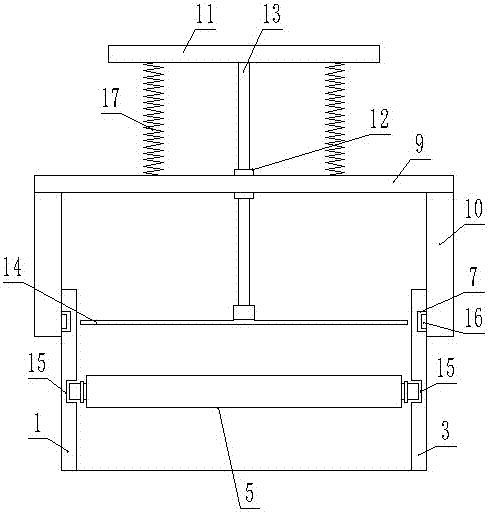

[0020] A high-efficiency rolling cutting machine for fried dough sticks, such as figure 1 , 2 As shown, it includes a frame for placing dough surrounded by four facades, the front facade 3, the rear facade 1, the left facade 2, and the right facade 4, and the pressure roller set relative to the frame. The surface roller 5, and the pressing and cutting device that is slidably arranged relative to the frame. The right facade 4 is hinged with the frame body, that is, the right facade 4 can rotate up and down along the frame body, and the edge trimming knife 6 is installed at the bottom of the right facade 4 . When the dough is rolled by the pressing roller 5, the right facade 4 is turned up, and the right facade 4 is in an open state. At this time, after being rolled by the pressing roller 5, the excess dough will overflow t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com