Simple-to-demount-and-mount rattan woven bed

A simple disassembly and rattan weaving technology, which is applied to beds, bed frames, sofas, etc., can solve the problems of insufficient firmness of the bed and poor air permeability, and achieve the effect of ingenious design, improved air permeability and comfort, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

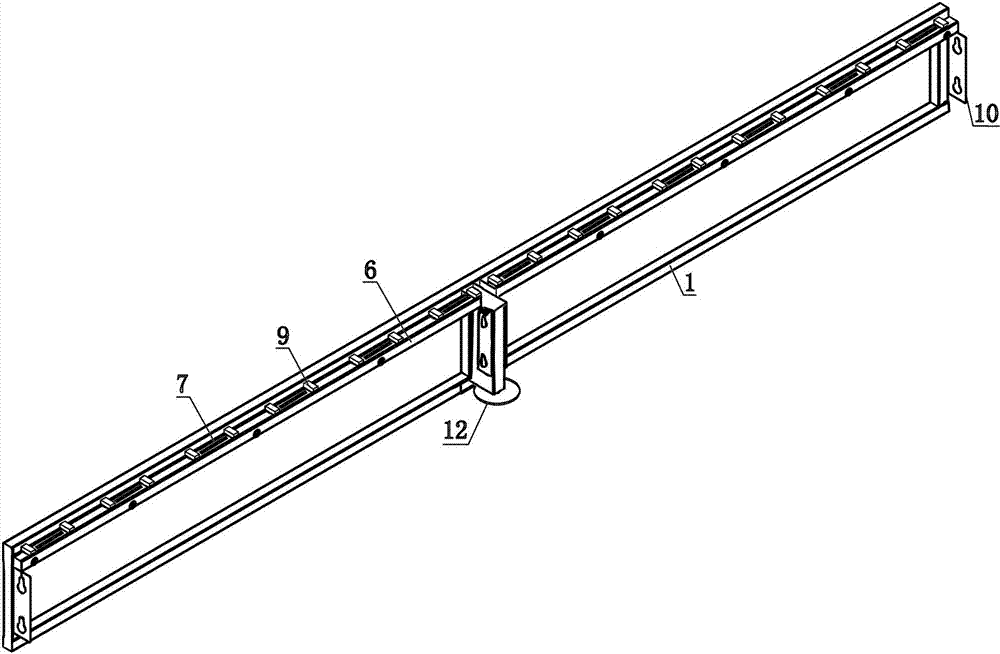

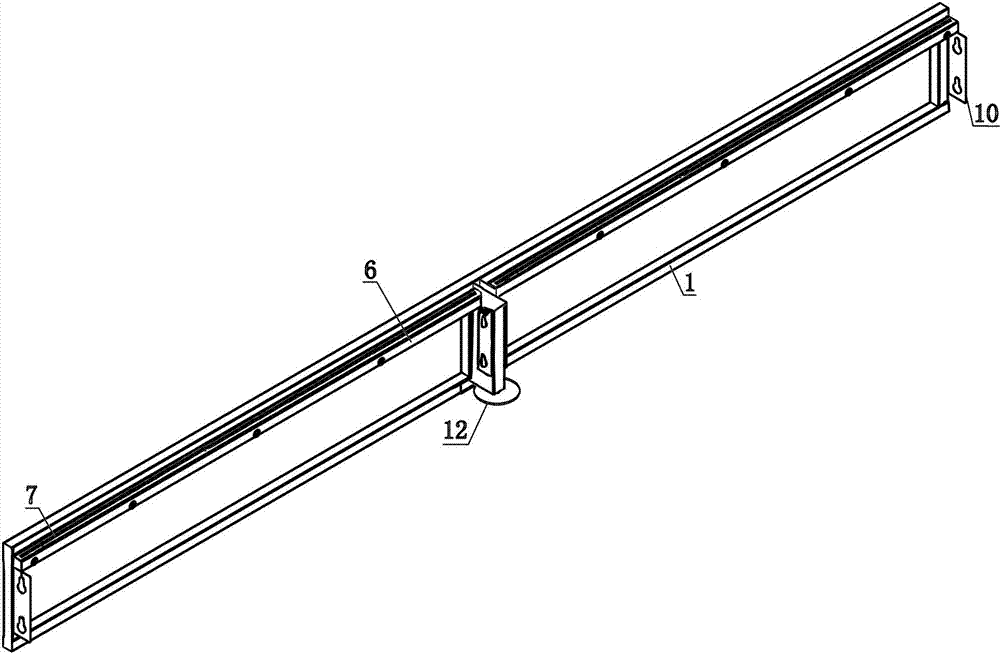

[0030] refer to figure 1 , Figure 7 , Figure 8 and Figure 9 . A woven rattan bed that can be easily disassembled includes six supporting frame boards 1 , a detachable bed frame 2 , a bed board 3 and a plurality of supporting feet 4 . The six support frames 1 are divided into two pieces on the left side, two pieces on the right side, and one piece on the front side and one on the rear side, and are detachably connected end to end in turn. The outer surfaces of the six support frame panels 1 are covered with rattan panels. 5. The rattan board 5 is made up of a plurality of vertical rattans 51 and a plurality of horizontal rattans 52, the plurality of vertical rattans 51 are arranged at intervals, and the plurality of horizontal rattans 52 are arranged from the arranged plurality of rattans. One side of the vertical rattans 51 passes through alternately up and down successively, two adjacent horizontal rattans 52 are arranged at intervals, and two adjacent horizontal ratt...

Embodiment 2

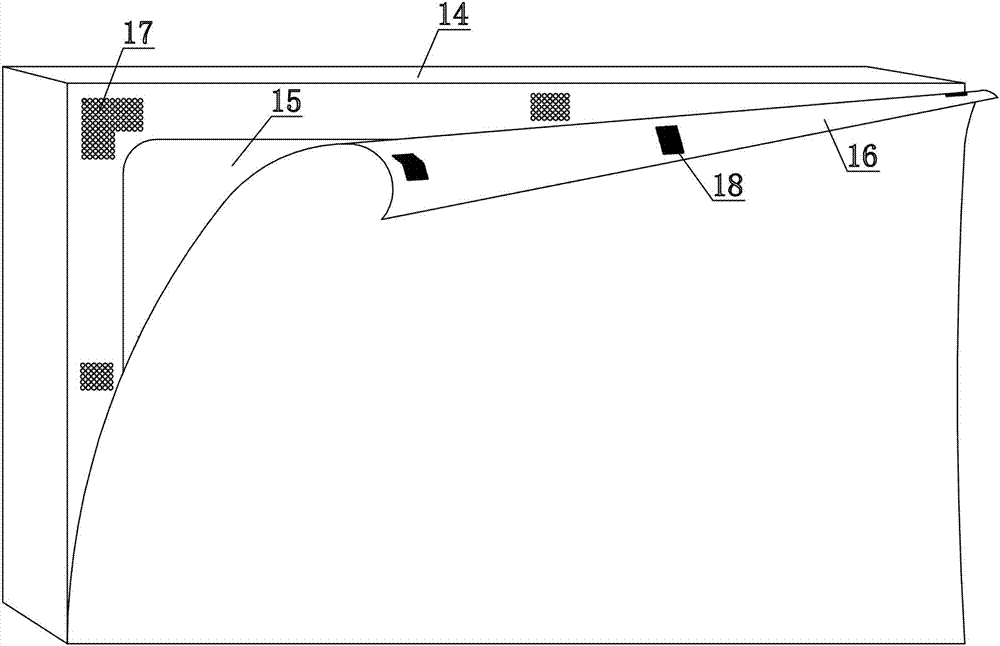

[0039] refer to figure 2 , Image 6 and Figure 9 . The specific implementation of this embodiment is basically the same as that of Embodiment 1, the difference is that: the upper part of the support frame plate 1 on the rear side is connected with a backrest 14 covered with a rattan board 5, and the backside of the backrest 14 is provided with There is an accommodating cavity 15 for accommodating the supporting frame board 1 , the disassembled bed frame 2 , bed board 3 and supporting feet 4 . The rear side of the backrest 14 is also provided with a non-woven fabric 16 for covering the mouth of the accommodating cavity 15, and the rear side periphery of the backrest 14 is provided with a Velcro female sticker 17, and the non-woven fabric 16 is provided with The Velcro female sticker 18 is compatible with the female Velcro sticker 17 . The setting of the backrest 14 can effectively rely on the human body, and the accommodating cavity 15 can effectively accommodate the hori...

Embodiment 3

[0041] refer to Figure 4 and Figure 5 . The specific implementation method of this embodiment is basically the same as that of Embodiment 2, the difference is that: the bed board 3 includes a plurality of rattan support plates 31, and the plurality of rattan support plates 31 are arranged in sequence from front to back , and the left and right ends of the plurality of rattan support plates 31 are respectively placed on the top surfaces of the corresponding support bars 6 . The bed board 3 includes a plurality of rattan support boards 31, which is conducive to improving the comfort of sleep, and can also improve the air permeability and stability of the bed board, so that the user's sleep is more refreshing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com