Glandless form magnetism-driven juicer with permanent magnet push-pull structure

A technology of magnetic drive and juicer, which is applied in household machinery for filtering food, household appliances, applications, etc. It can solve problems such as insufficient fluid lubrication and cooling of guide bearing parts, shaft locking accidents, and unstable operation, etc., to achieve convenience Safe operation for a long time, prolonging the service life, avoiding the effect of vibration or sudden change transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

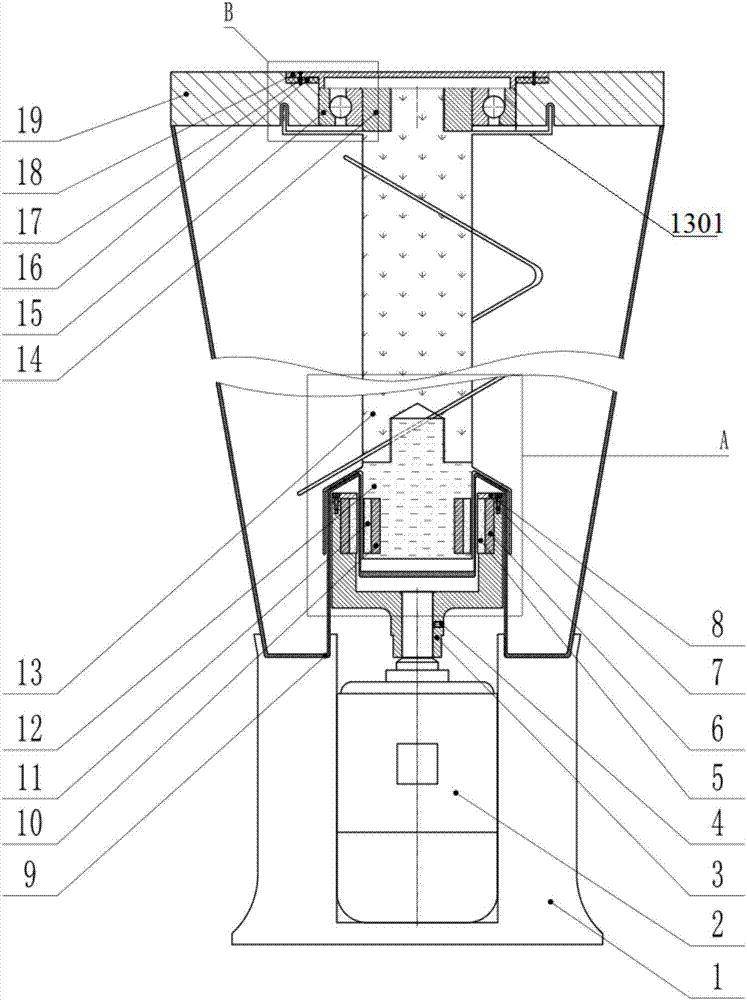

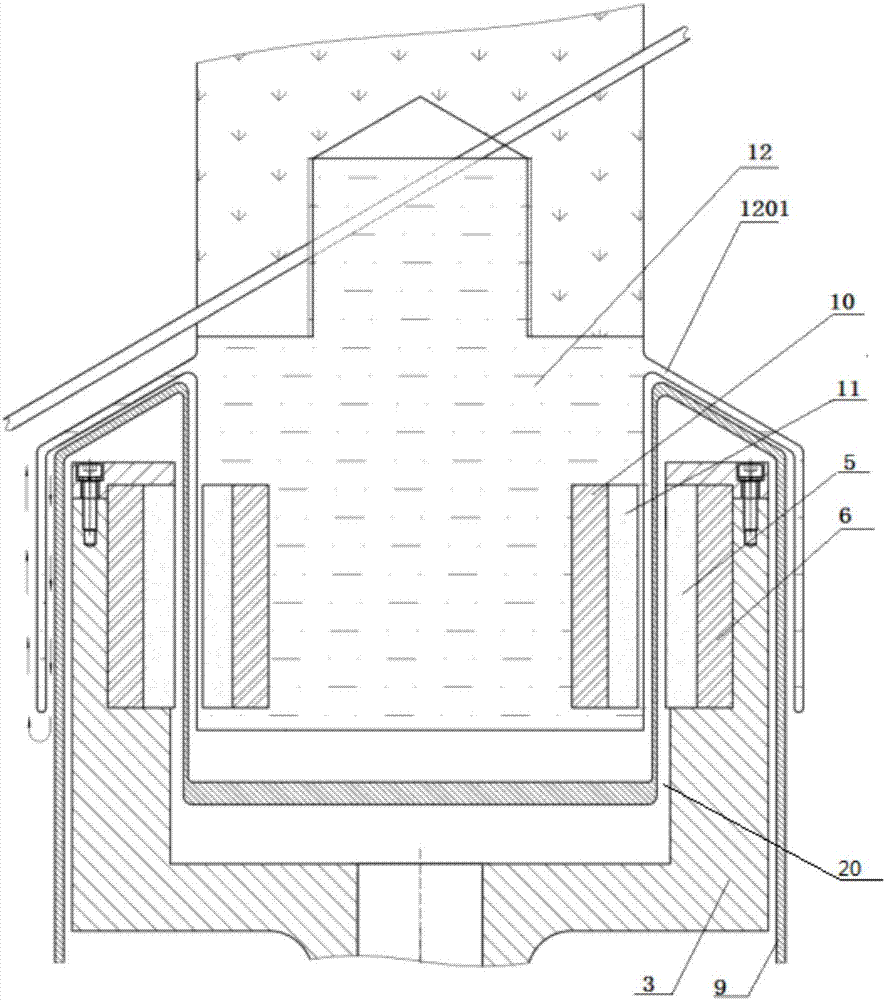

[0037] Such as figure 1 As shown, a permanent magnet push-pull structure magnetically driven juice extractor without a shaft seal structure according to the present invention includes a base 1, a cup body 9, a motor 2 arranged in the base 1, and a screw rod 13 located in the cup body 9 , the bottom shaft 12 positioned at the bottom end of the cup body 9 and the cup cover 19 positioned at the top end of the cup body 9 .

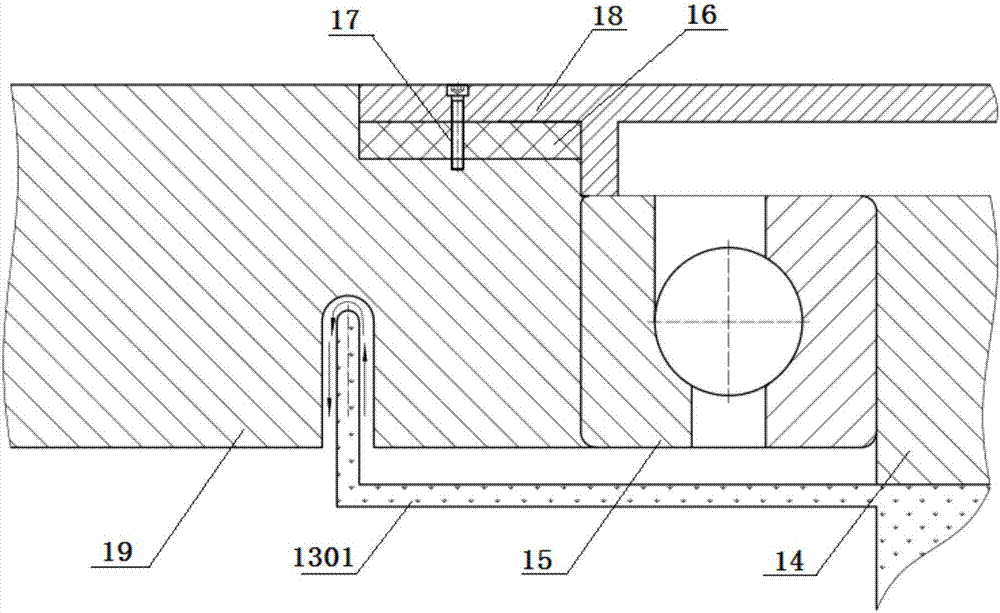

[0038] The cup body 9 is made of non-magnetic material, the bottom end of the cup body 9 is sealed, and the top end is open. The cup cover 19 is placed on the mouth of the cup body 9 and can seal the cup body 9. The shaft 14 is threaded, and the short shaft 14 is connected with the cup cover 19 through the bearing 15, the bearing 15 is provided with a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com