Catalyst for low-temperature catalytic combustion of chlorinated hydrocarbons, preparation method and application thereof

A low-temperature catalysis and catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, combustion method, physical/chemical process catalyst, etc., can solve the problems of many by-products, limited application, secondary pollution, etc., and achieve Strong resistance to chlorine poisoning, improved catalytic activity, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

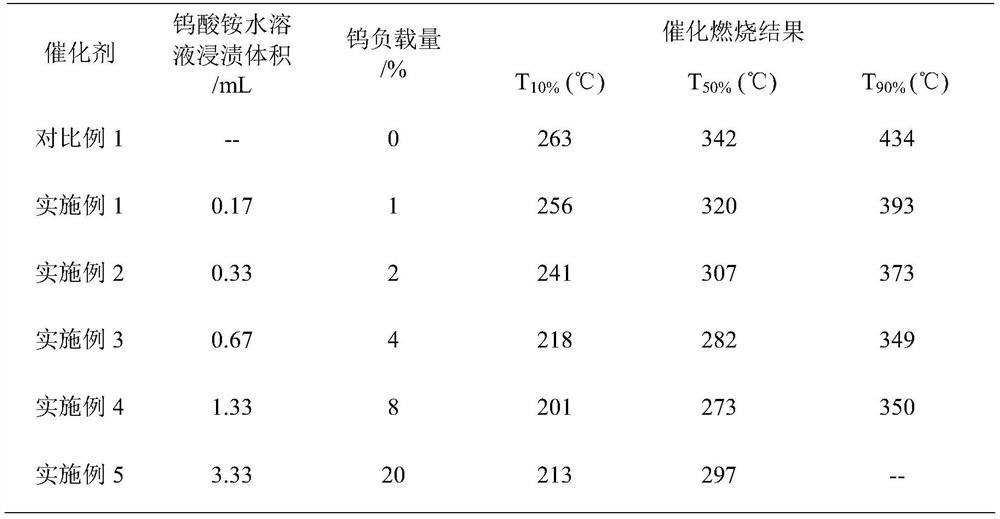

[0022] The preparation of embodiment 1~5 nanometer cerium oxide carrier supported tungsten catalyst

[0023] The commercially available ammonium tungstate is formulated into an aqueous solution with a concentration of tungsten element of 60g / L, as shown in Table 1, in Examples 1 to 5, the corresponding volume of ammonium tungstate aqueous solution is respectively impregnated into 1g of nano-cerium oxide carrier (according to comparative example 1 method of preparation). Stir evenly, stand overnight in the air at room temperature, place in a 110°C oven to dry for 12 hours, and then roast. The specific roasting process is: start heating at 50°C, and program the temperature at a rate of 100°C / hour (continuing 4 hours in total). Hours), calcined at 450°C for 2 hours, the obtained powder is the tungsten catalyst supported by nano-cerium oxide carrier.

[0024] By weight, Example 1 has a tungsten oxide loading of 1%, denoted as 1wt% W / CeO 2 ; The tungsten loading of Example 2 is 2...

Embodiment 6

[0027] Example 6: Catalytic combustion of catalysts with different tungsten loadings

[0028] Use the catalyzer of embodiment 1~5 and comparative example 1 to carry out the low-temperature catalytic combustion test of chlorobenzene respectively, all combustion tests are carried out in fixed-bed microreactor (3mm inner diameter quartz), and the consumption of catalyzer is 200mg, and temperature adopts K-type thermoelectric Even automatic control. Chlorobenzene is injected into the vaporization chamber by using 100 series KDS120 micro-injection pump from Stoelting Company of the United States, and then mixed with air into the reactor for combustion. The total flow is controlled by a mass flow meter, the concentration of chlorobenzene is 1000ppm, the amount of waste gas treated per gram of catalyst per hour is 30L, the linear velocity of the gas passing through the reactor is 100m / hour, and the reaction pressure is normal pressure. The relation of the conversion rate of chlorobe...

Embodiment 7

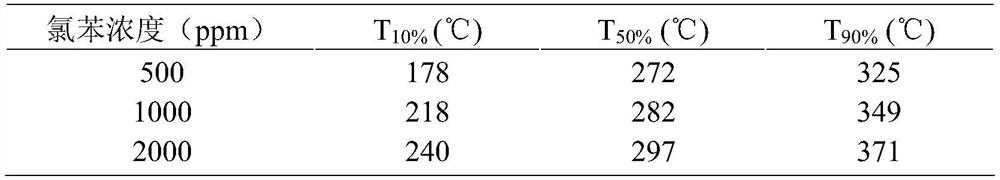

[0030] The chlorobenzene catalytic combustion of embodiment 7 different concentrations

[0031]According to the method of embodiment 6, change chlorobenzene concentration into 500ppm and 2000ppm and carry out combustion test respectively on the catalyst of embodiment 3, all the other reaction conditions are constant, combustion result is as shown in table 2.

[0032] Table 2 Catalyzed Combustion Results of Different Concentrations of Chlorobenzene on the Catalyst of Example 3

[0033]

[0034] It can be seen from Table 2 that when the concentration of chlorobenzene is 500-2000ppm, the catalysts of Example 3 all have relatively high catalytic activity, and can be widely used for catalytic combustion and elimination of chlorinated aromatic hydrocarbons with different concentrations. The catalytic activity increased in the catalytic combustion of chlorobenzene at a lower concentration, and its catalytic activity decreased slightly with the increase of chlorobenzene concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com