Water bed structure of composite cutting machine

A cutting machine and water bed technology, applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve the problems of low processing efficiency of water bed structures, achieve reliable processing, improve processing efficiency, and facilitate slag removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

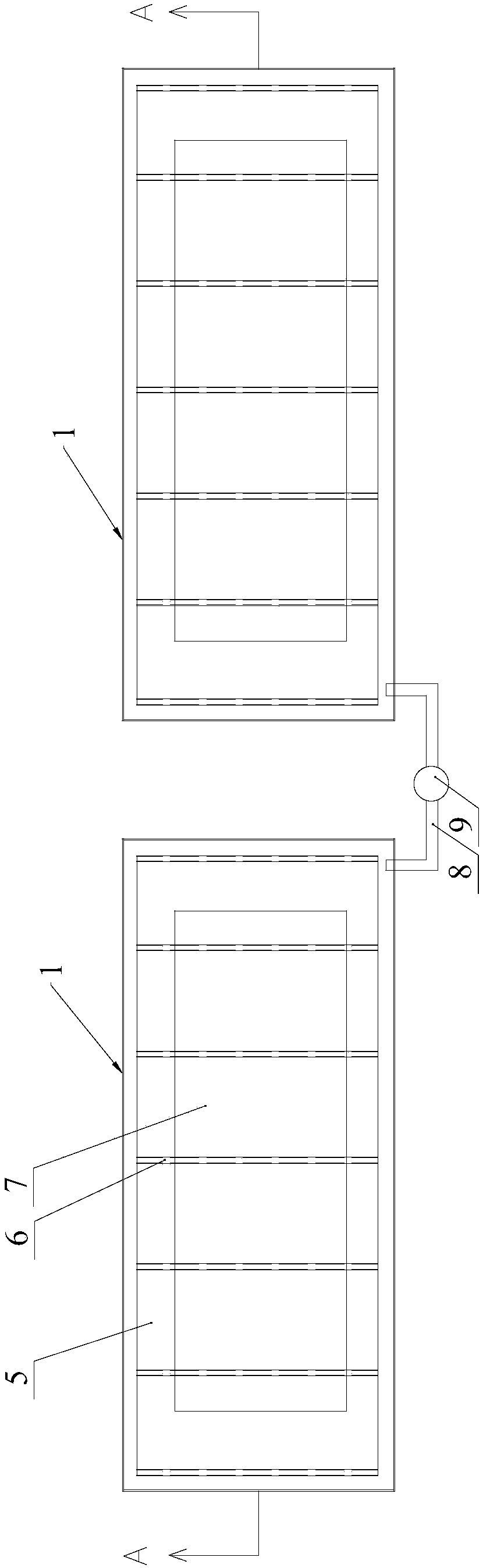

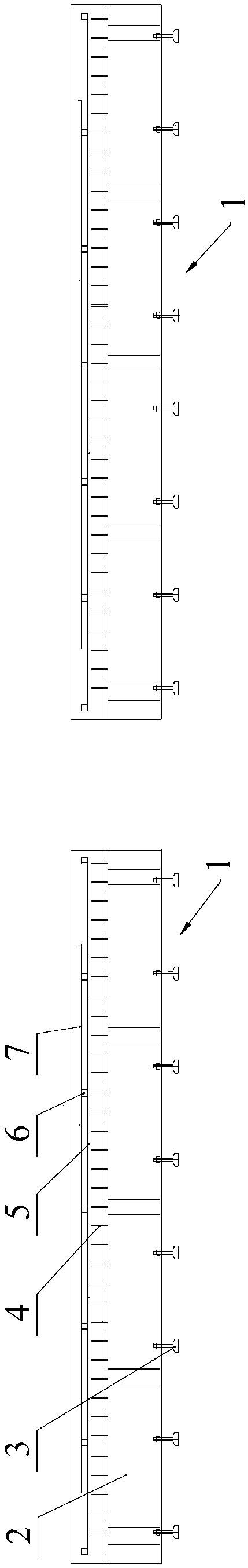

[0025] Below in conjunction with each accompanying drawing, the present invention is described in detail.

[0026] Such as figure 1 and 2 As shown, a water bed structure of a compound cutting machine includes at least two water bed bodies 1 arranged side by side. The flat plate 5 on the top has a gap between the flat plate 5 and the water storage tank 2, and several support bars 6 are arranged on the plate 5, and the support bars 6 are used to support the plate 7 to be processed; A water pipe 8 of a water storage tank 2, and a water delivery pump 9 is installed on the water pipe 8.

[0027] By arranging a plurality of water bed bodies 1, when the composite cutting machine processes the plate 7 to be processed on one of the water bed bodies 1, other water bed bodies 1 can carry out material handling and slag cleaning work, and the structure of the multiple water bed bodies 1 can Greatly improve processing efficiency. There is a water pipe 8 connecting two water storage tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com