High-efficiency separation and concentration device for waste slurry water in mixing plant

A technology of thickening device and mixing station, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., which can solve the problem that daily waste pulp water cannot be fully utilized and increase disposal costs , Uncertainty in the amount of concrete produced, etc., to achieve the effect of saving grinding costs, reducing disposal costs, and reducing the sand content of waste slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

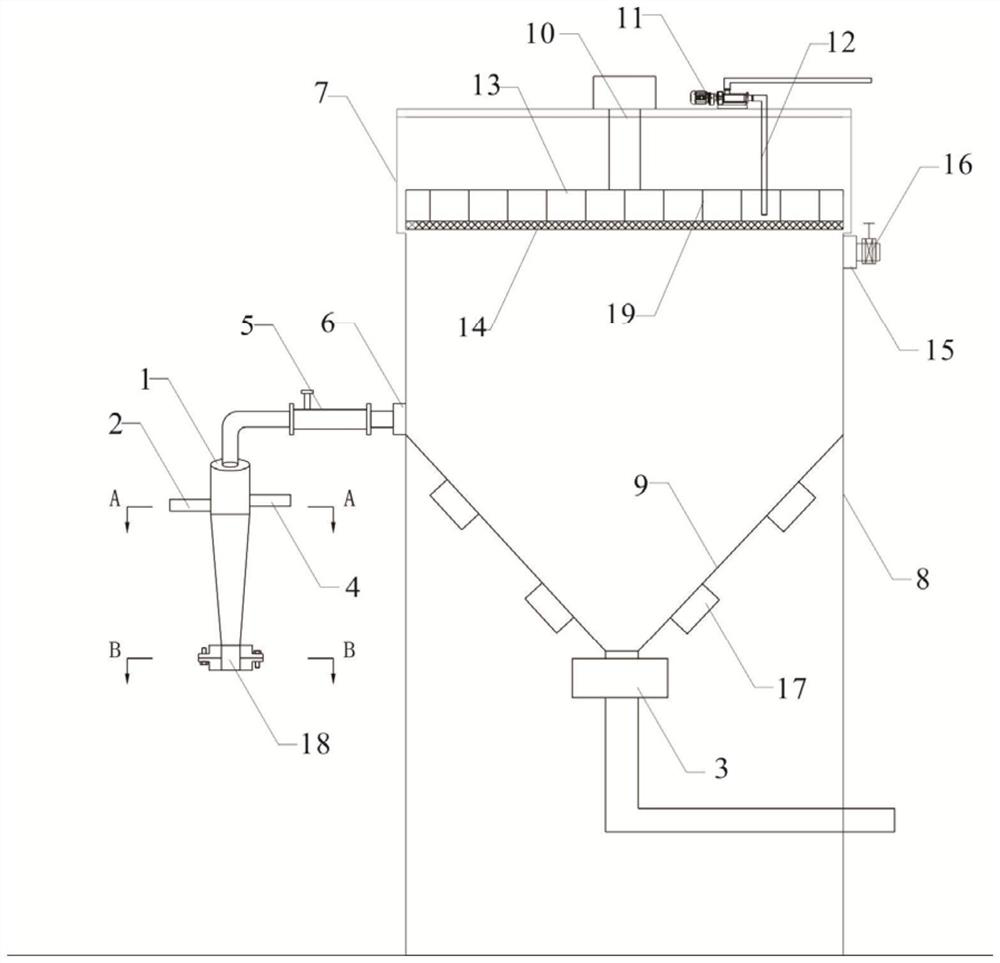

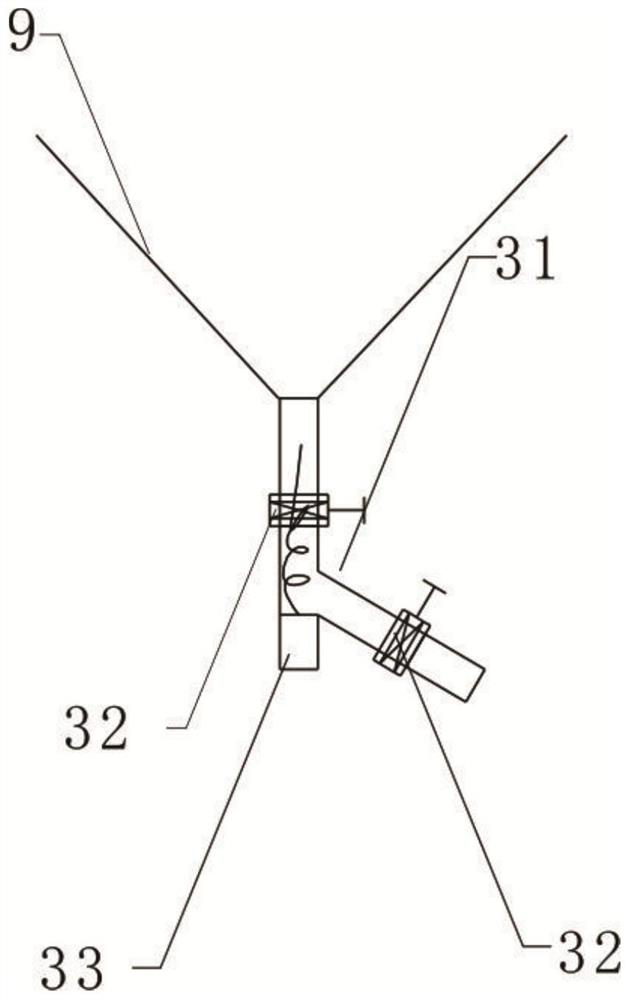

[0037] like figure 1 As shown, the high-efficiency separation and concentration device for waste slurry water in the mixing station includes a classification feeding device 1 and a concentration device; wherein, the classification feeding device 1 is composed of an upper circular cylinder and a lower conical cylinder.

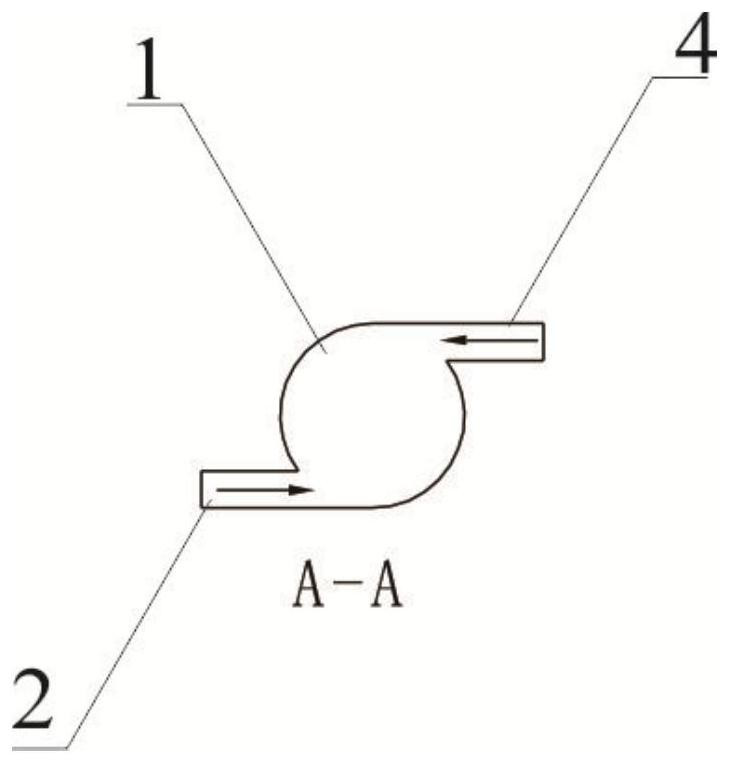

[0038] like figure 1 and figure 2 As shown, there are air inlets 4 and waste slurry water inlets 2 on the circular cylinder along its tangential direction, and the air pressure entering the air inlets 2 is not less than 12pa, and the waste slurry water is pumped from the waste slurry water inlet. 2 is pumped into the circular cylinder, and the air inlet 2 begins to introduce air to form a swirling flow, and then pump the waste slurry water. Therefore, both the air and the waste slurry water can form a swirling flow in the circular cylinder, and the classification treatment of the waste slurry water can be realized. The feed port 6 enters the concentration d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com