Novel automatic deviation adjusting roller set

A new type of technology for adjusting the deviation of the idler, applied in the direction of the roller, conveyor, conveyor objects, etc., it can solve the problems of easy wear and tear of the belt edge, unstable operation of the conveyor belt, skewed conveyor belt joints, etc. Automation and effectiveness, quick and easy deviation problems, the effect of a wide range of angle adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

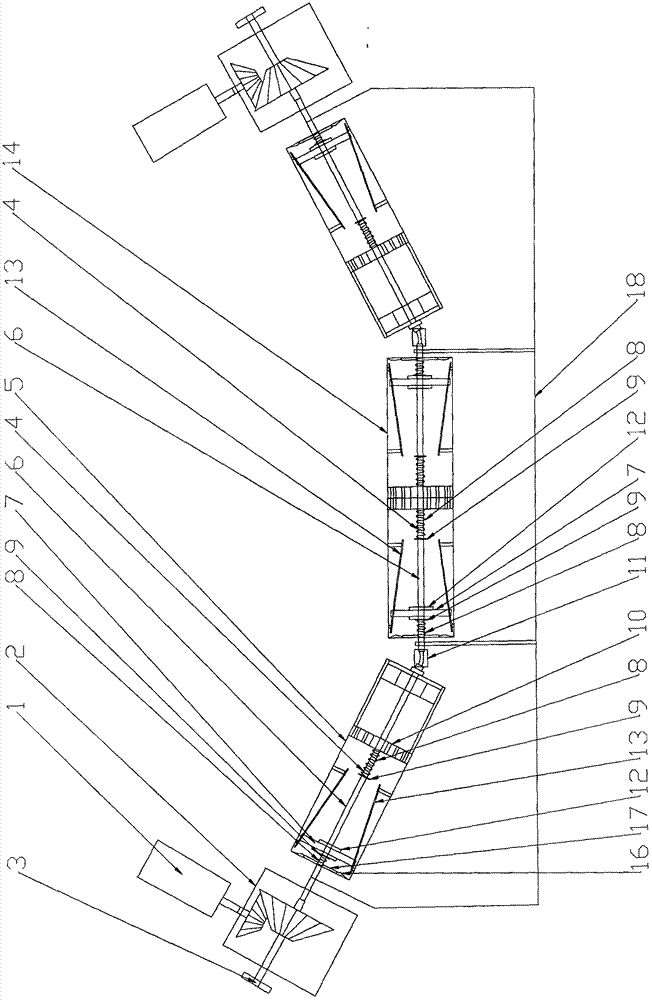

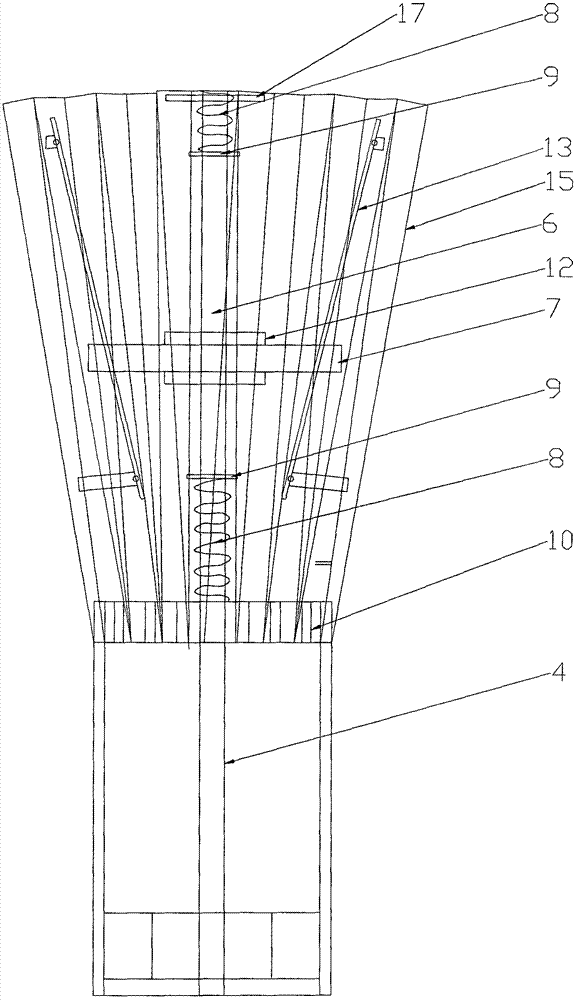

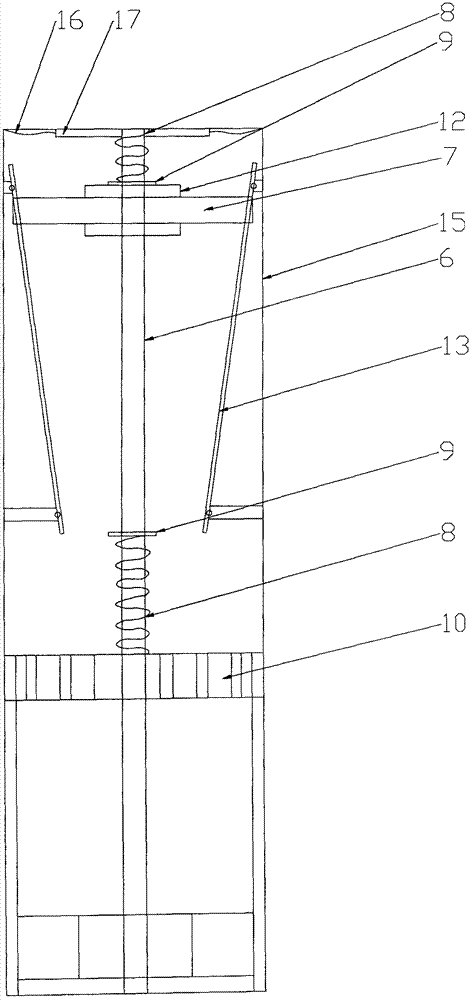

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a new type of automatic deflection adjustment idler group includes an idler frame 18 and an idler group and a deflection adjustment power structure arranged on the idler frame 18. The idler group includes a center idler and left and right symmetrical arrangements A pair of side rollers 5 on both sides of the center roller.

[0030] The side roller 5 includes a main shaft 4, an adjustment disc 7, a fixed disc 10, an adjustment screw 6, an adjustment nut 12, an adjustable support roller surface, and a fixed support roller surface. The adjustable support roller surface is composed of a plurality of support roller sheets 15 surrounds a cylindrical shape, and the lower end of each supporting roller sheet 15 is hinged with the fixed plate 10, and the inner side of the supporting roller sheet 15 is provided with an adjusting rod 13, and the distance between the upper end of the adjusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com