Separation method of high-boiling matter in 1-chloro-1,1-difluoroethane production process

A difluoroethane, production process technology, applied in the field of separation, can solve the waste of fluorine resources and other problems, achieve the effect of improving economic benefits and promoting further development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

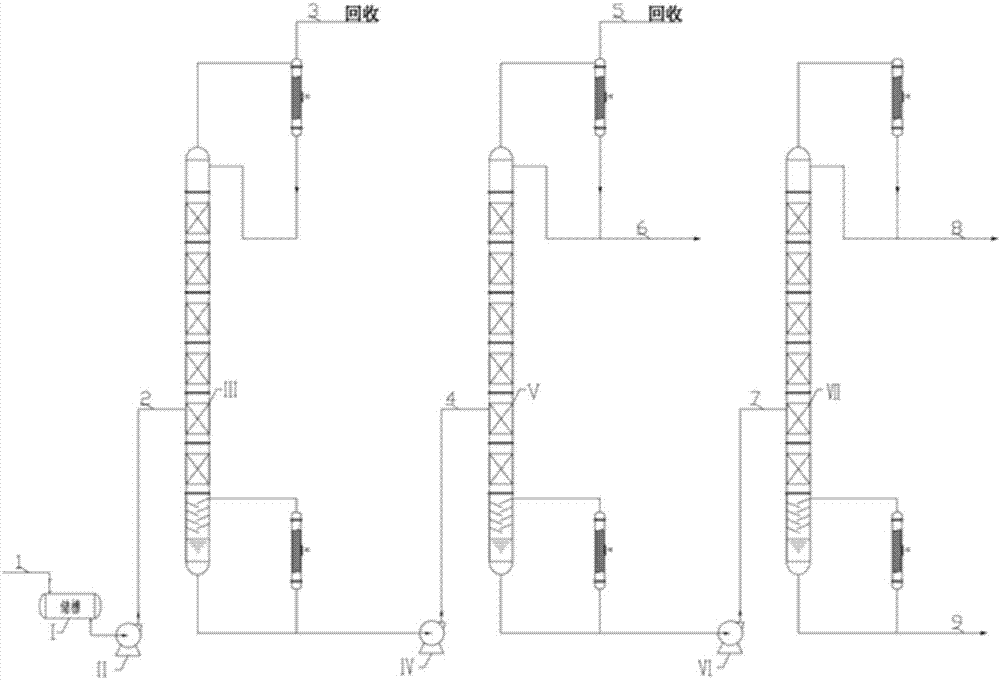

Image

Examples

Embodiment 1

[0051] The high boilers in the 1-chloro-1,1-difluoroethane (R142b) production process enter the degasser 2 tons of material from the high boilers storage tank through the material delivery pump 1#, and the fluctuation range of the control degasser operating parameters is : The temperature of the tower kettle is 55-60℃, the pressure of the tower kettle is 0.10-0.20MPa, the temperature of the tower top is 10-18℃, and the pressure of the tower top is 0.05-0.15MPa.

[0052] Gas chromatography was used to analyze and detect the samples at the top and bottom of the degassing tower. According to the sampling analysis results, when the components of the degassing tower are balanced, the light component 1-chloro-1,1-difluoroethane (R142b) in the high boilers is intermittently recovered from the top of the tower; When there is no 1-chloro-1,1-difluoroethane (R142b), feed to rectification column 1# through material delivery pump 2#.

[0053] Control the fluctuation range of operation pa...

Embodiment 2

[0059] The whole process is controlled by a continuous operation mode, and the fluctuation range of the operation parameters of the degassing tower is controlled: the temperature of the tower bottom is 60-70 ° C, the pressure of the bottom of the tower is 0.20-0.30 MPa, the temperature of the top of the tower is 18-27 ° C, and the pressure of the top of the tower is 0.15-0.25 MPa The operating parameters of rectification tower 1# fluctuate in the range of: tower kettle temperature 95-108°C, tower kettle pressure 0.15-0.20MPa, tower top temperature 65-78°C, tower top pressure 0.10-0.15MPa; rectification tower 2# The fluctuation range of the operating parameters is: the temperature of the tower bottom is 120-128°C, the pressure of the tower bottom is 0.15-0.20MPa, the temperature of the top of the tower is 95-103°C, and the pressure of the top of the tower is 0.10-0.15MPa.

[0060] The purity of recovered stream 3 is: 95.78wt% 1-chloro-1,1-difluoroethane (R142b), 4.22wt% difluoro...

Embodiment 3

[0062] The whole process is controlled by a continuous operation mode, and the fluctuation range of the operating parameters of the degassing tower is controlled: the temperature of the tower bottom is 70-80 ° C, the pressure of the bottom of the tower is 0.30-0.40 MPa, the temperature of the top of the tower is 25-40 ° C, and the pressure of the top of the tower is 0.25-0.35 MPa ; The fluctuation range of operating parameters of rectification tower 1# is: tower kettle temperature 110-120°C, tower kettle pressure 0.20-0.25MPa, tower top temperature 78-85°C, tower top pressure 0.15-0.20MPa; rectification tower 2# The fluctuation range of operating parameters is: the temperature of the tower bottom is 128-135°C, the pressure of the tower bottom is 0.20-0.25MPa, the temperature of the top of the tower is 103-110°C, and the pressure of the top of the tower is 0.15-0.20MPa.

[0063] The purity of recovered stream 3 is: 94.39wt% 1-chloro-1,1-difluoroethane (R142b), 5.61wt% difluorodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com