A method for correcting deviation and lifting by grouting in the transition section of track, road and bridge

A transition section and grouting technology, applied in the directions of roads, tracks, laying tracks, etc., can solve the problem of limited adjustment value of fasteners, and achieve the effect of reliable effect, economical cost and good environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

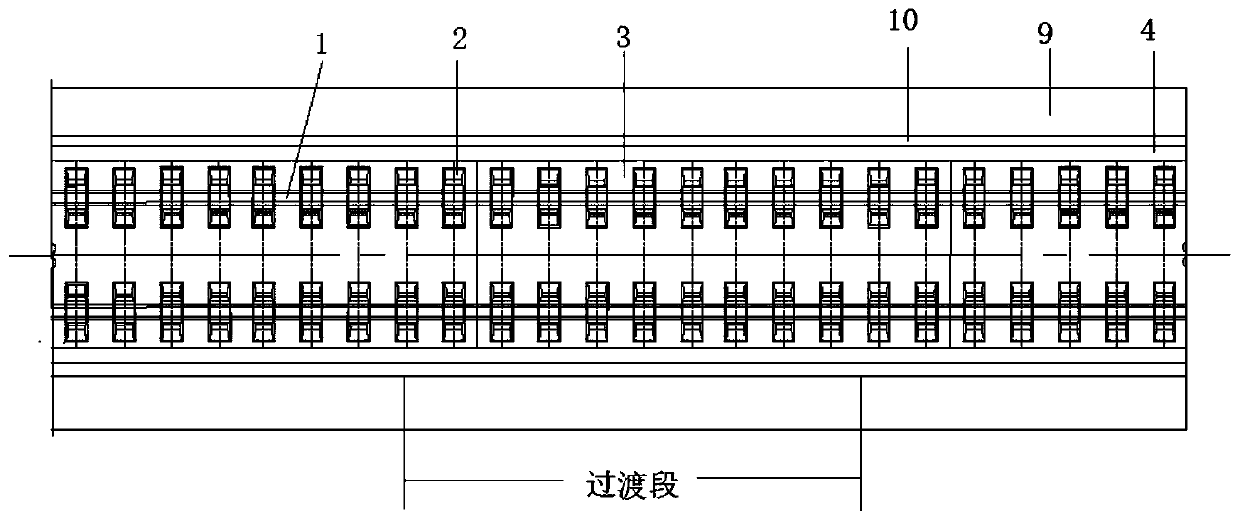

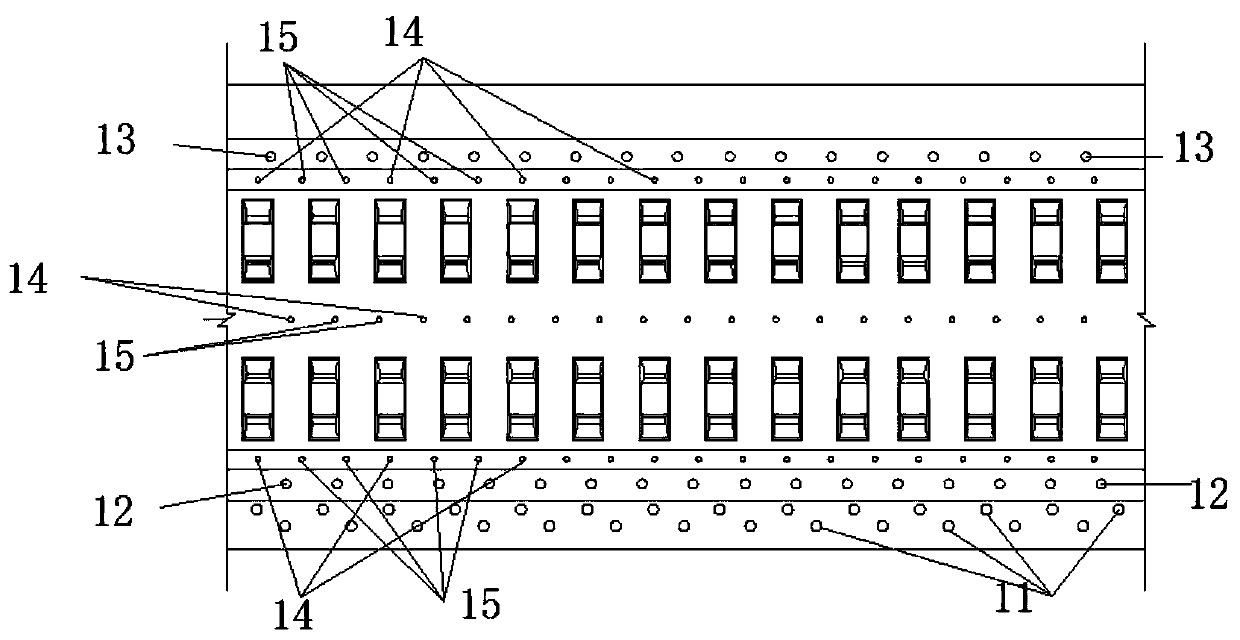

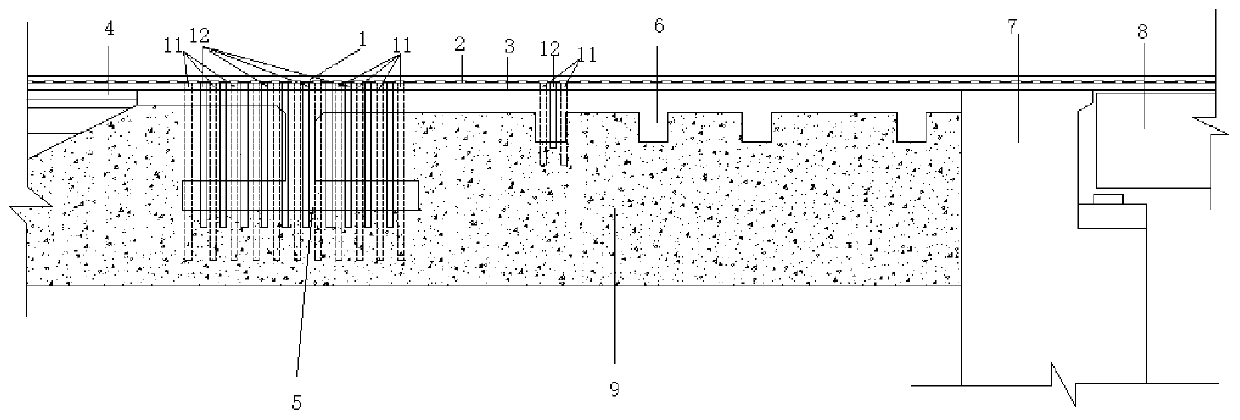

[0030] In the figure, 1 is the track, 2 is the rail platform, 3 is the track plate, 4 is the base plate, 5 is the big end thorn, 6 is the small end thorn, 7 is the abutment, 8 is the beam body, 9 is the subgrade, 10 is the On the road shoulder, 11 is the grouting hole for the support pile, 12 is the deviation correction hole at the end thorn, 13 is the pressure relief hole, 14 is the grouting lifting hole, and 15 is the filling hole. The dotted line in the figure indicates the part that was not cut when drawing the drawing.

[0031] On the road shoulder 10 of the subgrade 9 of the road bridge transition section, a base plate 4 is provided, and a track plate 3, a rail platform 2 and a steel rail 1 are sequentially arranged on the base plate 4. In addition, on the subgrade 9, under the base plate 4, a The large end thorns 5 and the small end thorns 6 poured together with the base plate.

[0032] Drill support pile grouting holes 11 vertically on the subgrade 9 on the side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com