Construction method achieving fiber continuity at joint in process of pouring concrete for certain times

A construction method and concrete technology, applied in the direction of building, building components, building structure, etc., can solve the problems of reducing the overall performance of the structure, discontinuous fibers, unable to make full use of structural materials, etc., to achieve good promotion prospects, excellent structural performance, The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

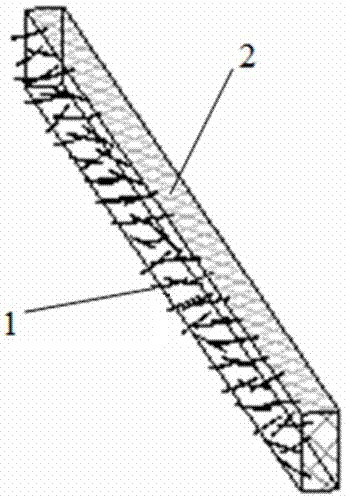

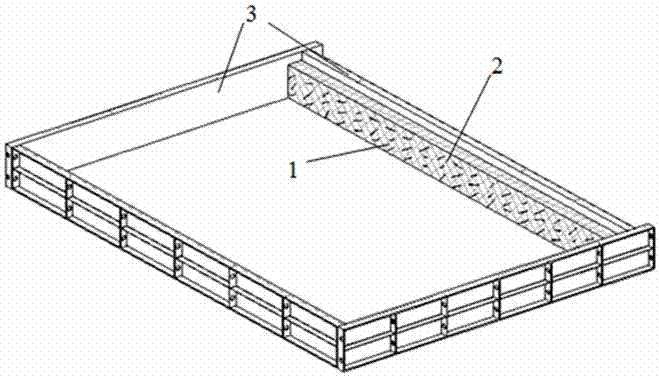

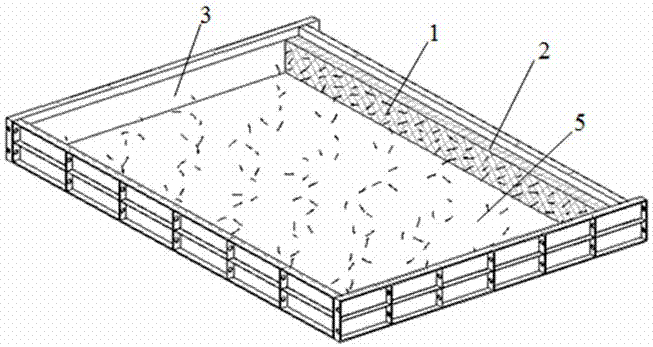

[0024] Such as Figure 1~7 As shown, the construction method of the present invention to achieve fiber continuity at the joints during the staged concrete pouring process is to partially penetrate the fibers 1 into the connecting plate 2 along the length direction, and then install the template 3 at the preset concrete joint interface 4. , The fiber-free side of the connecting plate 2 is tightly attached to the inside of the form 3, and then the concrete 5 is poured and cured; the formwork and the connecting plate at the joint interface are removed, so that the fiber 1 penetrating the connecting plate is exposed to the joint For the joint interface 4, the template 3 is installed and the next concrete 6 is poured and cured, so that the fibers 1 are connected to the adjacent different batches of concrete.

[0025] It specifically includes the following steps:

[0026] 1) Insert the fiber 1 evenly into the connecting plate 2 by pressing, etc., the insertion depth is about half of the...

Embodiment 2

[0039] In the precast concrete structure, each precast concrete structure is connected as a whole by a cast-in-place belt (cast-in-situ section). During the preparation of the precast concrete structure, it is necessary to set the fiber-attached connecting plate on the side connected with the cast-in-situ belt (cast-in-situ section) in advance according to the method in Example 1, so that the side of the obtained precast concrete structure has fibers protruding from The cast-in-situ belt (cast-in-situ section) concrete connection.

[0040] The method of the present invention can increase the connection performance of the interface by adjusting the fiber content and the slenderness ratio on the joint interface, avoiding the behavior of enhancing the mechanical performance of the interface by changing the shape of the interface, setting the connecting piece or setting the special-shaped steel plate, etc. To ensure the performance of the structure at the joints, and reduce engineeri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com