Fabricated shear wall suitable for frame shear wall structure and mounting method thereof

An installation method and shear wall technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of not considering connections, restricting the application of prefabricated shear walls, and increase scalability and expand application forms. and application range, the effect of ensuring the overall seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the above-mentioned features and advantages of the patent of the present invention more comprehensible, the following specific examples are given together with the accompanying drawings and described in detail as follows.

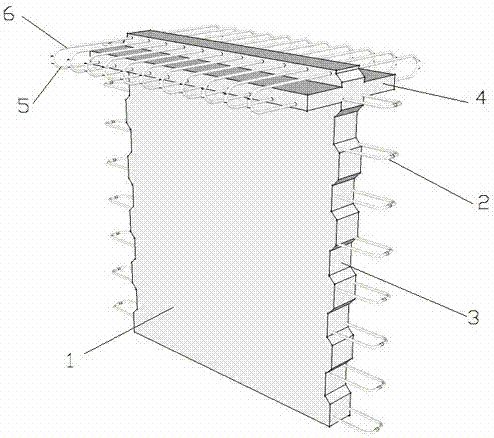

[0018] A prefabricated shear wall suitable for a frame shear wall structure, including a wall of the shear wall, a plurality of U-shaped horizontal steel bars are arranged on both sides of the wall, the U-shaped horizontal steel bars open toward the wall, and the U-shaped horizontal The steel bars are arranged at equal intervals in the vertical direction, and the two sides of the wall are provided with U-shaped horizontal steel bars as concave-convex surfaces, and an overhanging plate is set near the top of the wall, and the floor is pre-embedded in the overhanging plate for stress The ribs are pre-embedded floor negative ribs in the wall above the overhanging plate body, and the ends of the stressed ribs extending out of the overhang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com