Outdoor telegraph pole mounting equipment

A technology for installing equipment and utility poles, applied in the field of utility poles, and can solve the problems of low work efficiency, vertical utility poles, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

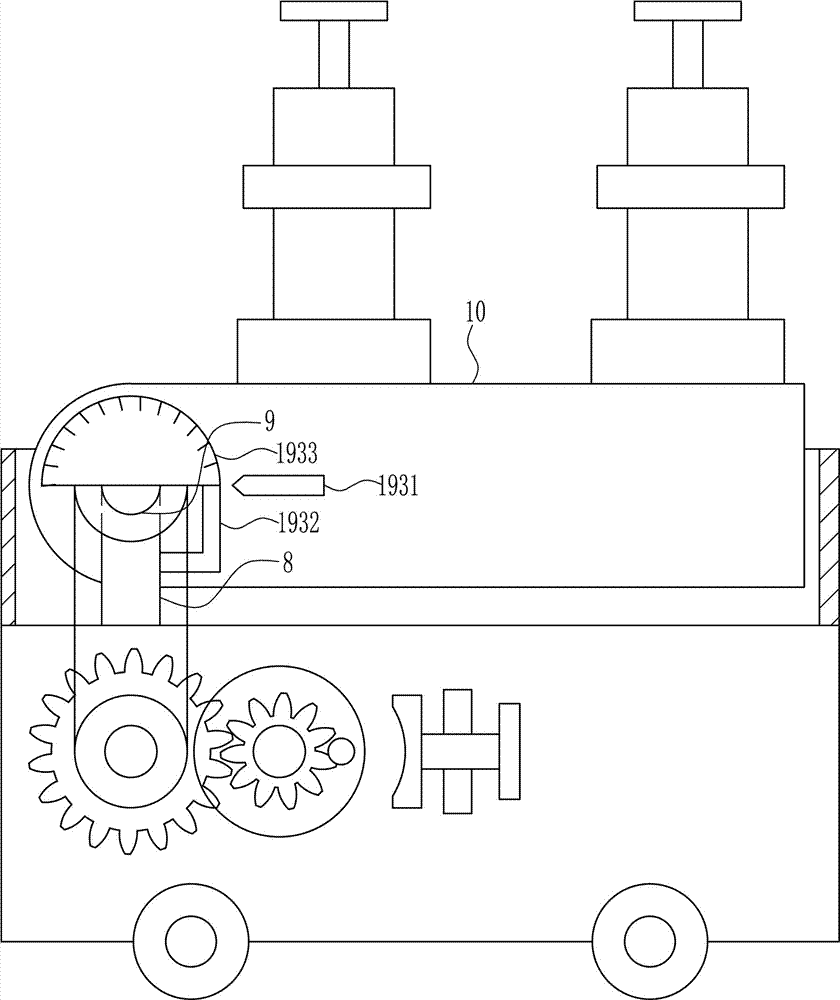

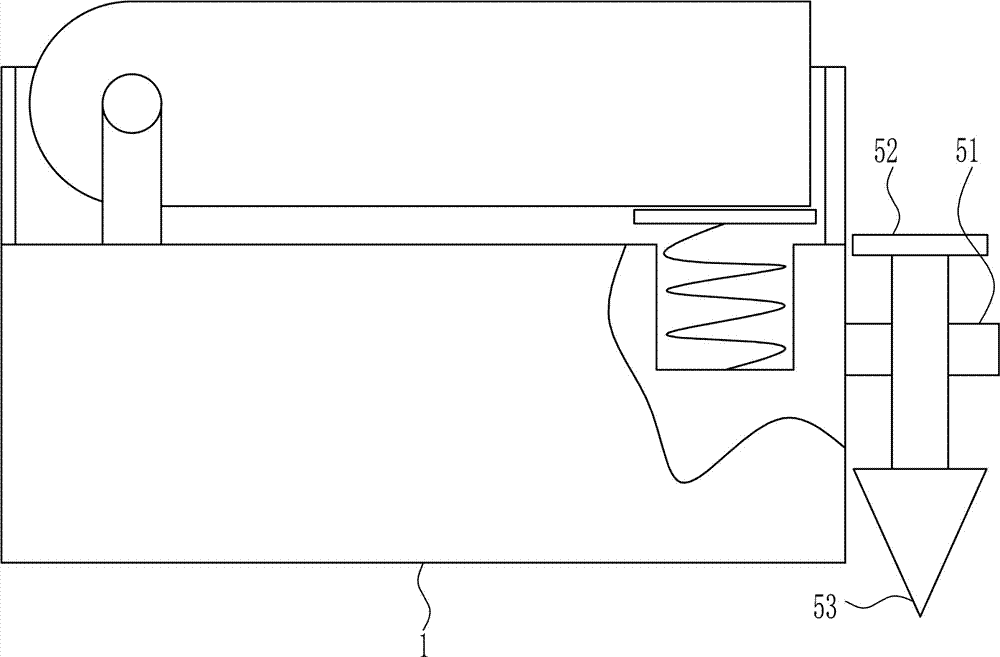

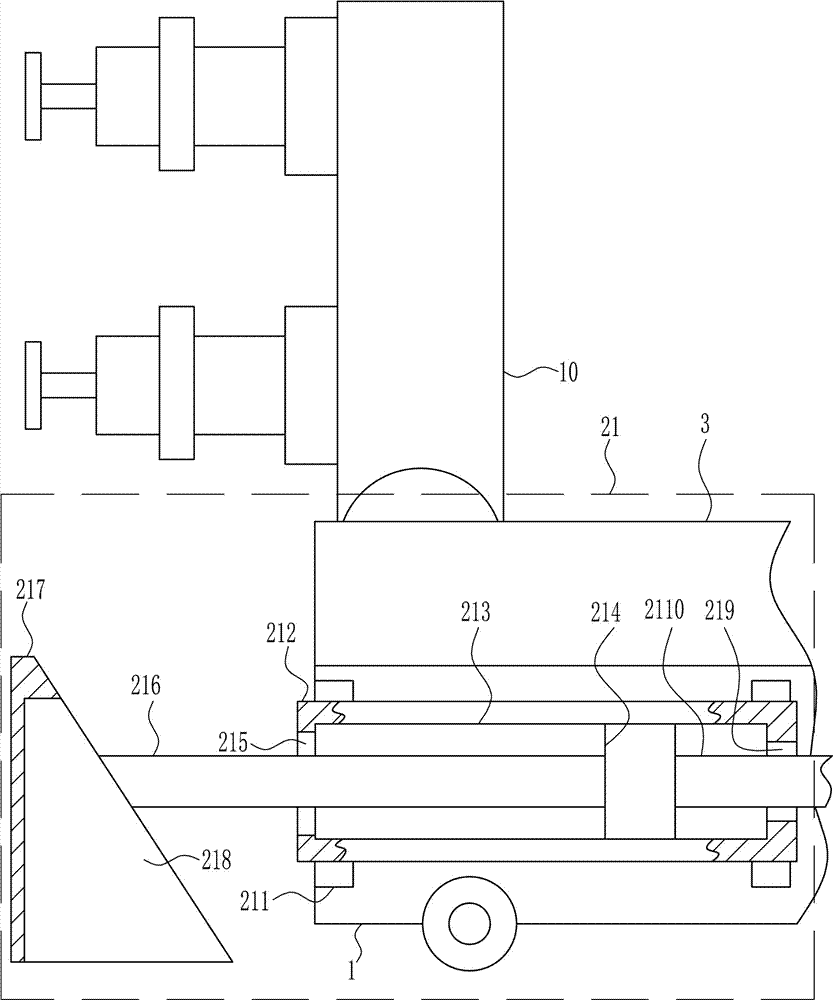

[0042] An outdoor pole-mounted device such as Figure 1-8 Shown, include mobile platform 1, wheel 2, workbench 3, spring 6, buffer plate 7, first support seat 8, first rotating shaft 9, rotating plate 10, push handle 11, place block 12, fixed plate 13, The first slide rail 14, the first slider 15, the pressing plate 16 and the first screw rod 18, the lower side of the mobile platform 1 is rotatably connected with the wheels 2, and the upper side of the mobile platform 1 is equipped with a workbench 3 by welding, and the workbench 3 There is a first empty slot 4 on the top, and a second empty slot 5 is opened on the right side of the mobile platform 1. The second empty slot 5 communicates with the first empty slot 4, and the inner and lower side walls of the second empty slot 5 are welded. A spring 6 is installed, a buffer plate 7 is installed on the upper end of the spring 6 by welding, a first support seat 8 is installed on the left side of the mobile platform 1 by welding, t...

Embodiment 2

[0044] An outdoor pole-mounted device such as Figure 1-8 Shown, include mobile platform 1, wheel 2, workbench 3, spring 6, buffer plate 7, first support seat 8, first rotating shaft 9, rotating plate 10, push handle 11, place block 12, fixed plate 13, The first slide rail 14, the first slider 15, the pressing plate 16 and the first screw rod 18, the lower side of the mobile platform 1 is rotatably connected with the wheels 2, and the upper side of the mobile platform 1 is equipped with a workbench 3 by welding, and the workbench 3 There is a first empty slot 4 on the top, and a second empty slot 5 is opened on the right side of the mobile platform 1. The second empty slot 5 communicates with the first empty slot 4, and the inner and lower side walls of the second empty slot 5 are welded. A spring 6 is installed, a buffer plate 7 is installed on the upper end of the spring 6 by welding, a first support seat 8 is installed on the left side of the mobile platform 1 by welding, t...

Embodiment 3

[0047] An outdoor pole-mounted device such as Figure 1-8 Shown, include mobile platform 1, wheel 2, workbench 3, spring 6, buffer plate 7, first support seat 8, first rotating shaft 9, rotating plate 10, push handle 11, place block 12, fixed plate 13, The first slide rail 14, the first slider 15, the pressing plate 16 and the first screw rod 18, the lower side of the mobile platform 1 is rotatably connected with the wheels 2, and the upper side of the mobile platform 1 is equipped with a workbench 3 by welding, and the workbench 3 There is a first empty slot 4 on the top, and a second empty slot 5 is opened on the right side of the mobile platform 1. The second empty slot 5 communicates with the first empty slot 4, and the inner and lower side walls of the second empty slot 5 are welded. A spring 6 is installed, a buffer plate 7 is installed on the upper end of the spring 6 by welding, a first support seat 8 is installed on the left side of the mobile platform 1 by welding, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com