Spring bolt door closing automatic popping device

A technology of automatic pop-up and lock tongue, which is applied in the direction of building locks, buildings, building structures, etc., can solve the problems of loud closing sound and lock tongue wear, and achieve the effect of reducing the sound of closing the door, avoiding friction and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

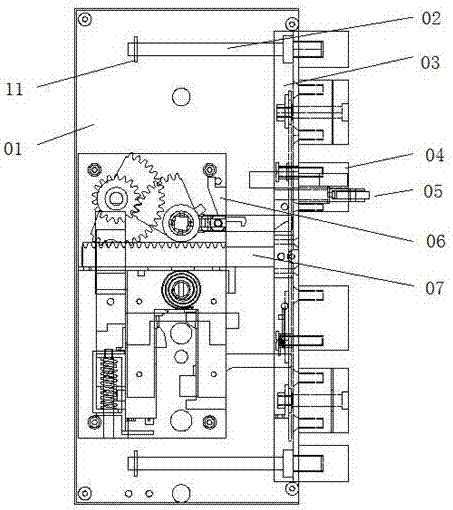

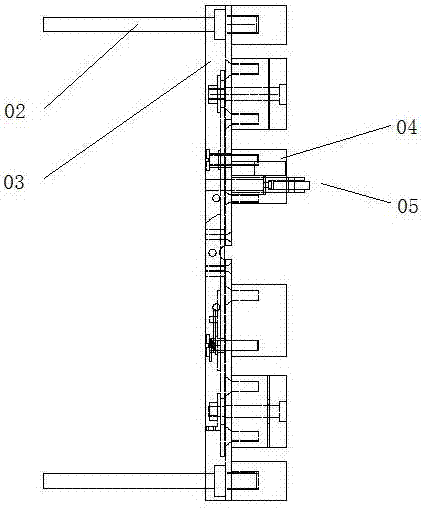

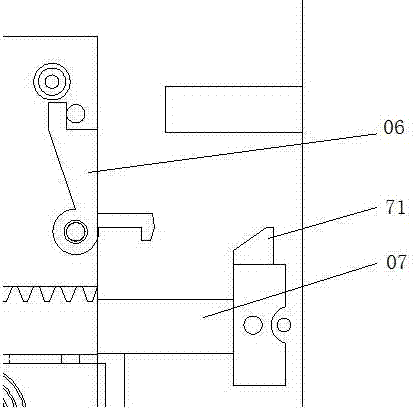

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, the automatic pop-up device for closing the deadbolt includes a bottom plate 01, a support plate 11 arranged on the bottom plate 01, a deadbolt bottom plate 03, a guide rod 02 and a deadbolt 04 fixedly connected to the deadbolt bottom plate 03, the deadbolt The bottom plate 03 is fixedly connected with the pull rod 07, and the connection between the pull rod 07 and the deadbolt bottom plate 03 is provided with a buckle protrusion A71, and the bottom plate 01 is rotatably connected with a dead bolt buckle 06, and the dead bolt buckle 06 is provided with a buckle Protrusion B, when the door is opened, the buckle protrusion B is buckled on the buckle protrusion A71; the lock tongue 04 is provided with a touch device 05, and the touch device 05 includes a touch lever 51, a touch head 52 and a touch bearing 53; the door is closed At this time, the door frame presses the touch bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com