Air spring

A gas spring and cylinder technology, applied in the field of gas springs, can solve certain problems such as the inability to achieve the buffer effect, and achieve the effect of enhancing the buffer effect and ensuring the rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

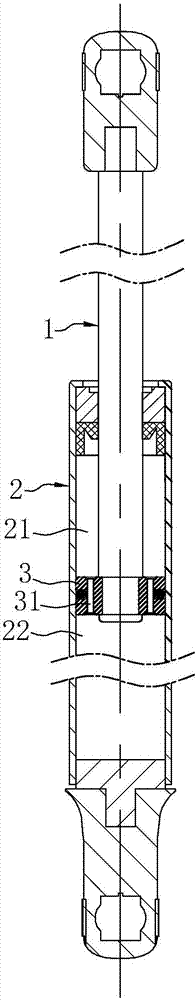

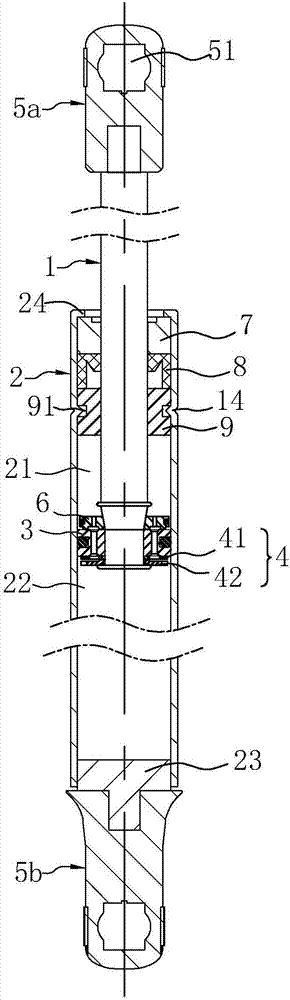

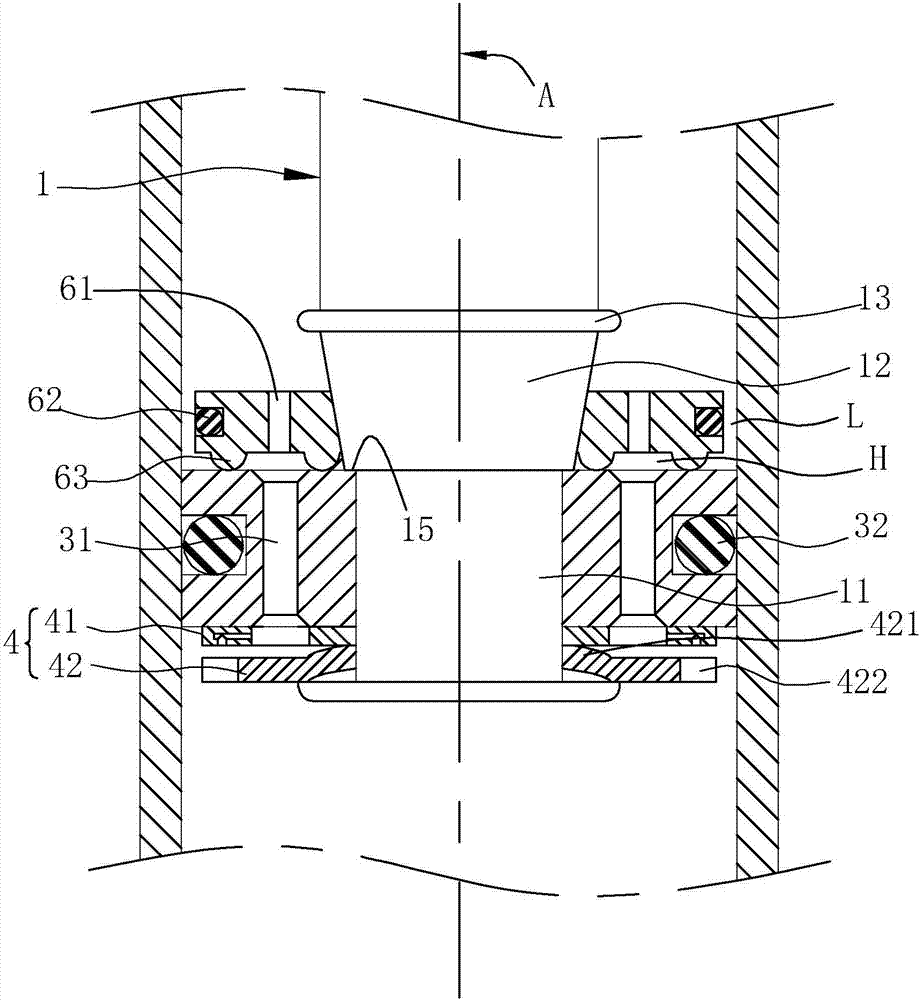

[0040] see figure 2 , a gas spring, including a cylindrical cylinder 2, the cylinder 2 is hollow filled with a filler, in this embodiment the filler is a mixture of oil and gas. One end side of the cylinder body 2 is blocked by a closed seat 23, a cylinder side bracket 5b is fixed on the closed seat 23, a piston rod 1 is inserted from the other end of the cylinder body 2, and a part of the piston rod 1 protrudes from the cylinder body 2, and the piston rod side bracket 5a is fixed at its end, and the cylinder side bracket 5b and the piston rod side bracket 5a are both provided with mounting holes 51.

[0041] One end of the cylinder body 2 away from the closed seat 23 is sequentially accommodated with a guide sleeve 7, an oil seal 8 and a spacer 9, and an annular small-diameter portion 14 is provided on the outer wall of the cylinder body 2, and the annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com