Gear selecting and shifting operating mechanism for automotive transmission

A technology of automobile transmission and control mechanism, which is applied in the direction of instruments, controlled components, mechanical equipment, etc., can solve the problems of reduced efficiency of shift cable, limitation of leverage ratio, and influence on shift quality, so as to improve the quality of shift selection and increase The Effect of Election Shift Leverage Ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

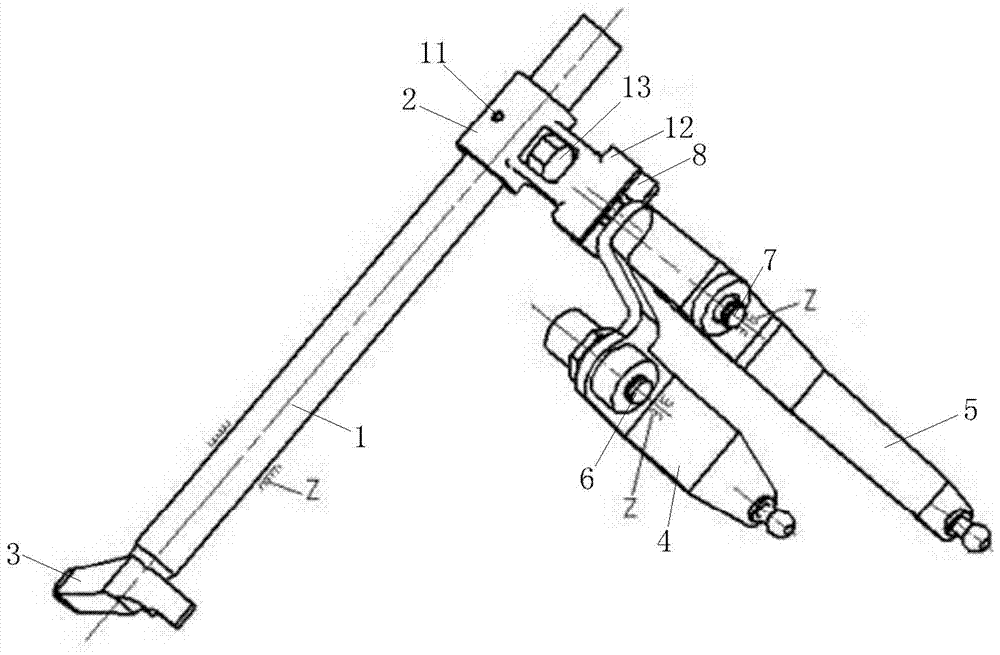

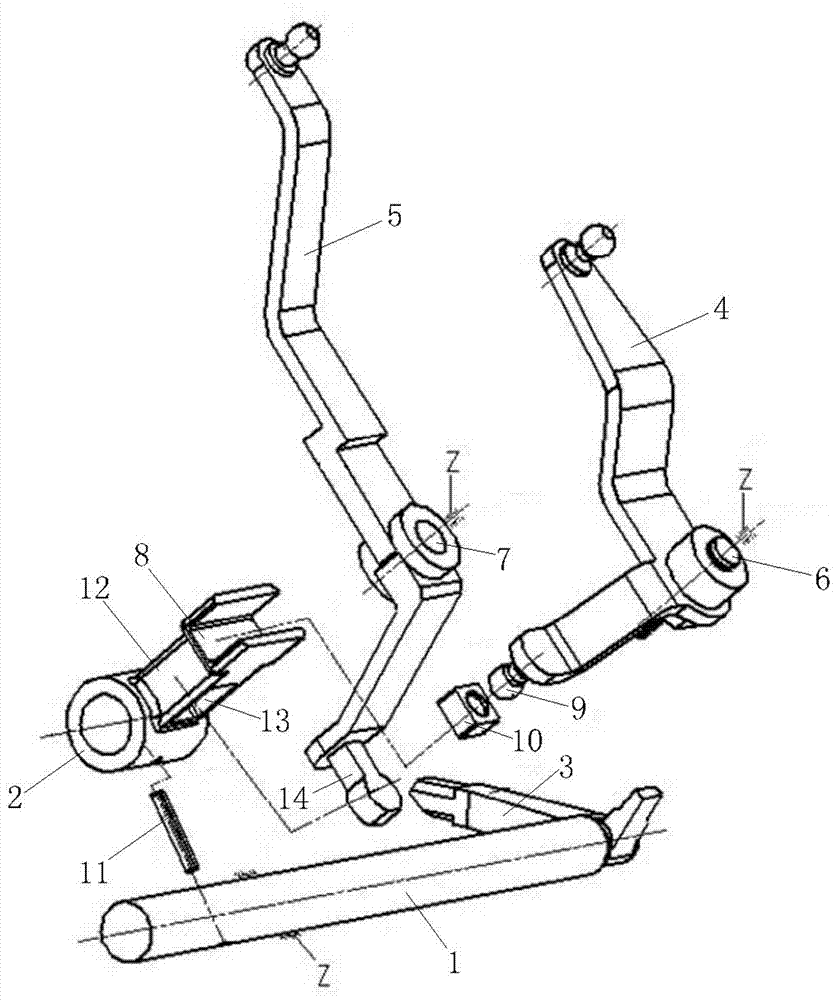

[0019] Such as figure 1 and figure 2 The shifting control mechanism of the automobile transmission shown is set in the transmission housing Z, including a shift shaft 1 capable of reciprocating rotation at a certain angle along its central axis and capable of reciprocating translation along the axial direction for a certain distance and fixed on the shift shaft 1. On the shift block 2, one end of the shift shaft 1 is provided with a shift lever 3, and the shift block 2 is connected with a select rocker 4 and a shift rocker 5, and the select rocker 4 is connected with the selector Between the gear blocks 2, there is a step-off structure for restricting the movement of the gear selection rocker 4 with the selection of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com