High-temperature-resistant valve

A technology of high temperature resistance and valve, applied in the direction of valve details, valve device, valve housing structure, etc., can solve the problems of poor sealing, complex valve structure, etc., and achieve the effect of small thermal expansion coefficient, stable chemical performance and internal compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

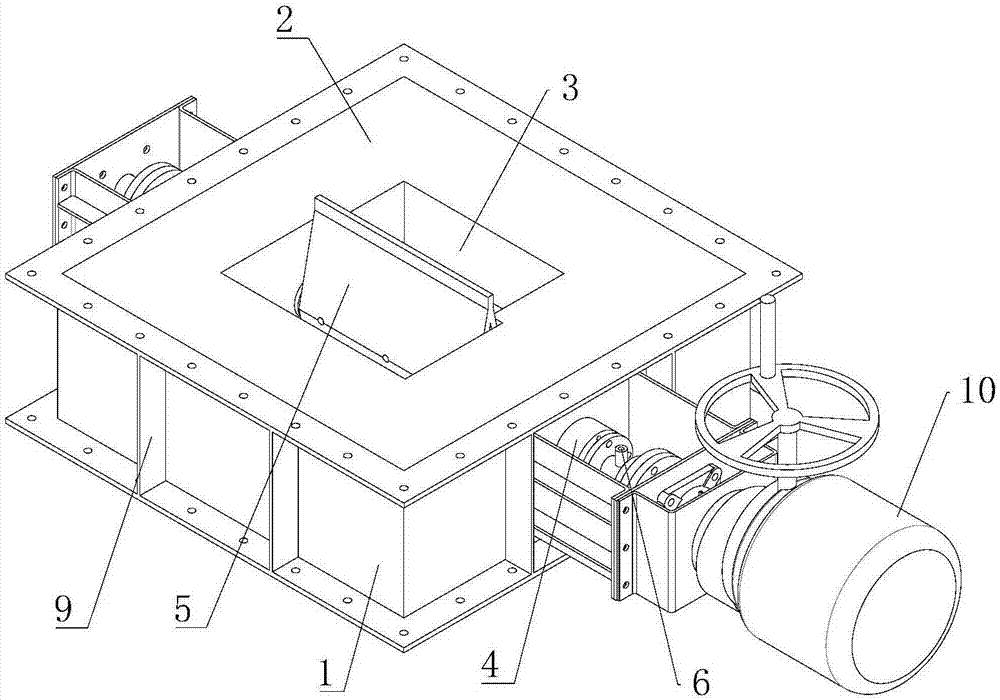

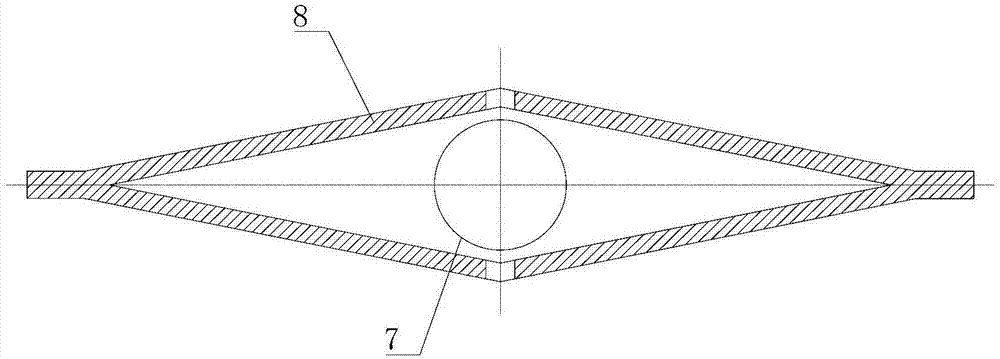

[0029] like figure 1 As shown, it is an embodiment of the high temperature resistant valve of the present invention. This embodiment includes a valve body 1, the valve body 1 is a hollow rectangular structure, and its middle part is filled with a lining 2 made of refractory castable material. A vent hole 3 is opened in the middle of the lining 2, and a rotating shaft 4 runs through the vent hole 3, and a blade 5 is fixed on the rotating shaft 4, and the blade 5 is adapted to the vent hole 3. The rotating shaft 4 drives the vane 5 to rotate to realize the on-off of the valve. This inner lining 2 formed of refractory castable has excellent resistance to flex cracking and dynamic fatigue, relatively low coefficient of thermal expansion and contraction, simple construction, high temperature resistance not lower than 1000 degrees Celsius, and comprehensive performance is more obvious than other similar products improve. During the construction process, it is necessary to strictly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com