Anti-drawing flexible pipe connector

A technology for anti-drawing flexible and pipes, applied in the direction of pipes/pipe joints/fittings, hose connection devices, mechanical equipment, etc., can solve the problem of no anti-drawing device, uneven foundation, large, or blockage in pipes It is necessary to add reinforcement piers and other problems at the head and turning places to achieve the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

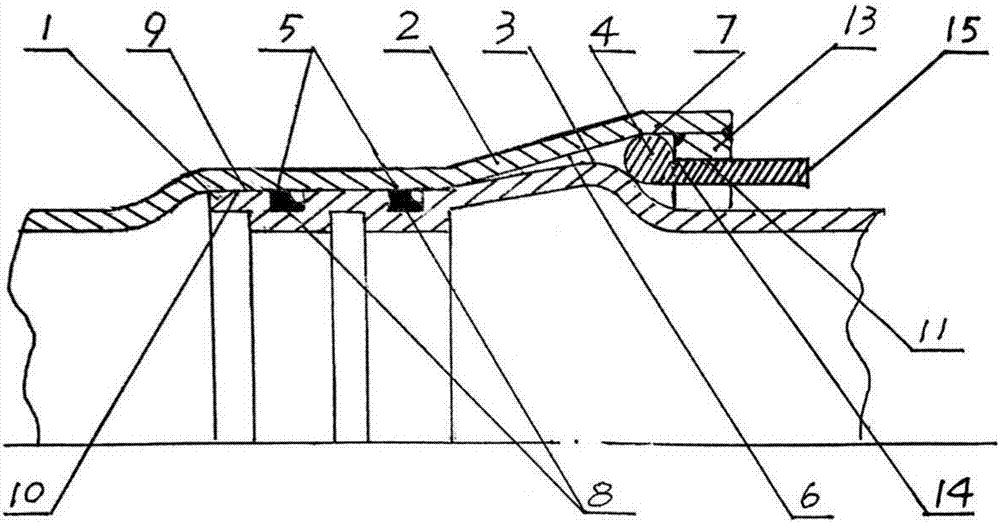

[0025] An embodiment of the pullout-resistant flexible pipe interface of the present invention, as attached figure 1 As shown, including a plug 1 and a socket 2 that cooperate with each other;

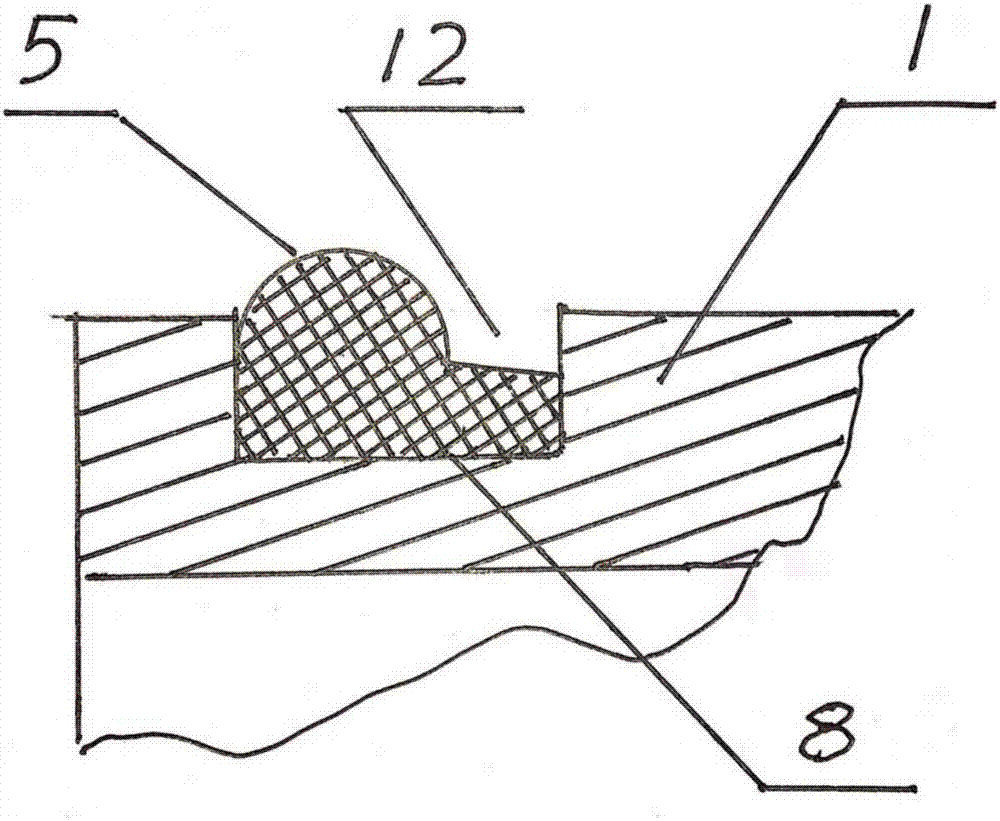

[0026] The plug 1 includes a protruding platform 9 sequentially connected inwardly from the port, a supporting protuberance 3 and a plug 1 connecting end for connecting pipes, and the outer diameter of the protruding platform 9 is smaller than that of the supporting protruding 3 Outer diameter, the outer diameter of the support protrusion 3 is greater than the outer diameter of the connecting end of the plug 1;

[0027] The socket head 2 includes an inner port 11 connected in sequence from the port inward, a conical slope 6 with a gradually reduced i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com