High-power three-ring-fire stove burner

A high-power, burner technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of small power adjustable range, inconvenient use, deflagration and insufficient combustion, etc., to achieve a large power range, The effect of complete combustion and sufficient primary air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

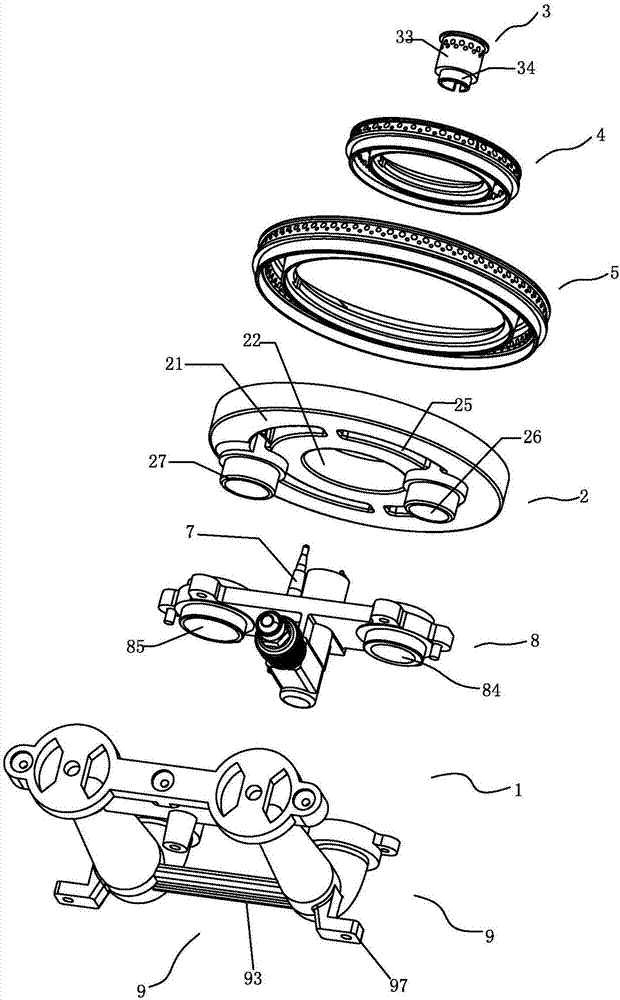

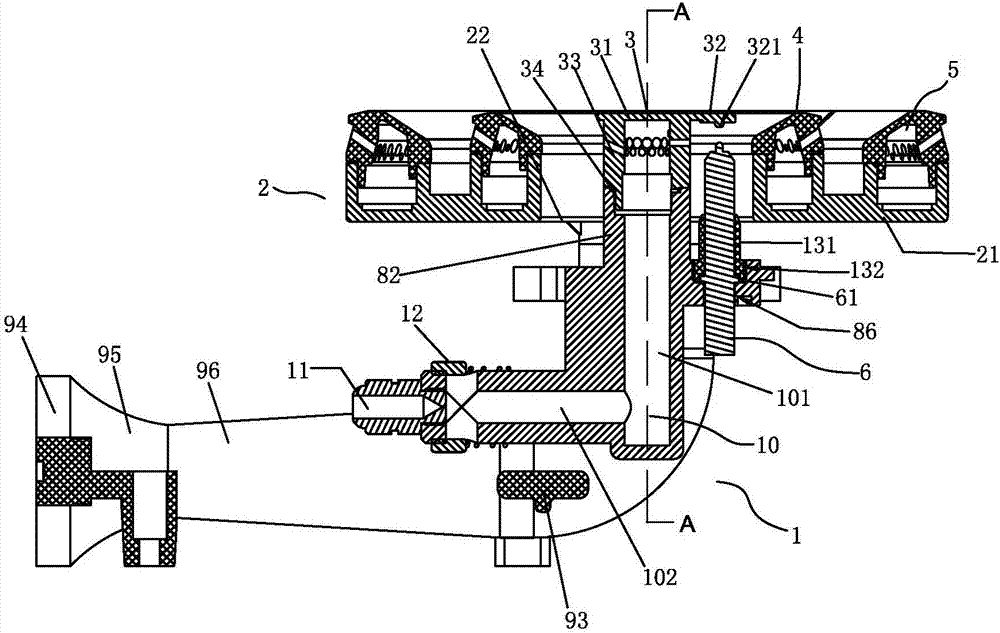

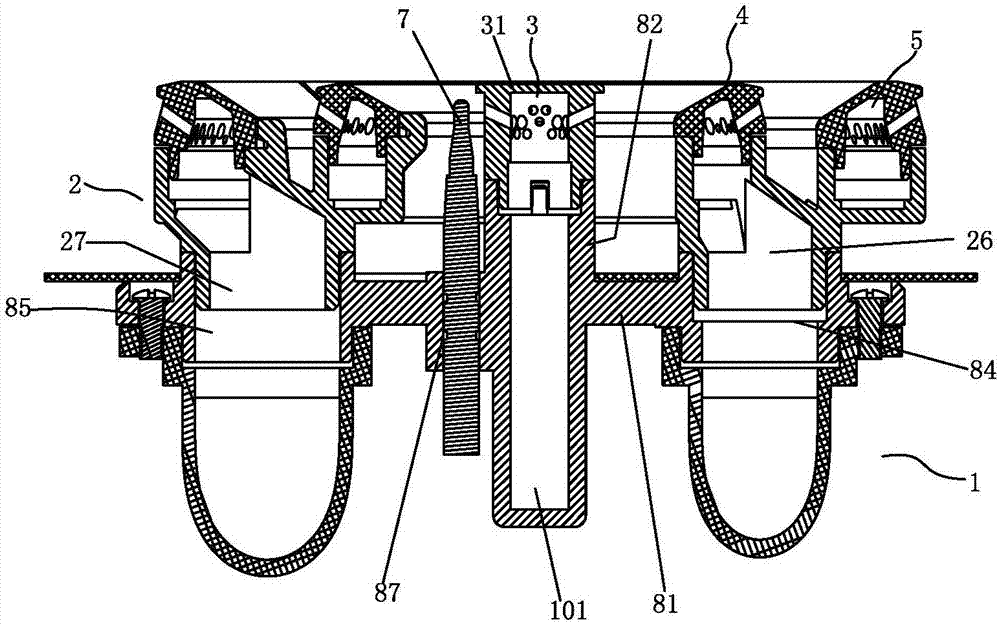

[0033] like figure 1 As shown, a high-power three-ring fire cooker burner includes a burner head 1, a fire distribution seat 2, a central fire cover 3, an inner ring fire cover 4, an outer ring fire cover 5, an ignition needle 6 and an induction needle 7, The furnace head 1 includes a head portion 8 and an injection pipe portion 9,

[0034] The head 8 includes a seat plate 81, a central fire cover seat 82 arranged at the center of the upper surface of the seat plate, a central injection tube assembly 83 arranged on the center lower surface of the seat plate, an outer ring air guide channel 85 arranged at one end of the seat plate, and an The inner ring air guide channel 84 at the other end of the plate, the inner and outer ring air guide channels 84, 85 extend to the upper surface and the lower surface of the seat plate; the seat plate is provided with an ignition pin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap