a reaction kettle

A reactor and reaction technology, applied in chemical/physical/physicochemical fixed reactors, chemical/physical/physicochemical processes using energy, chemical/physical/physicochemical processes, etc., can solve the problem of increasing the manufacturing cost of reactors , increase the floor area of the reactor, prone to air leakage and other problems, to achieve the effect of large adjustable power range, compact structure, and improved heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solution of the present invention, the reaction kettle provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

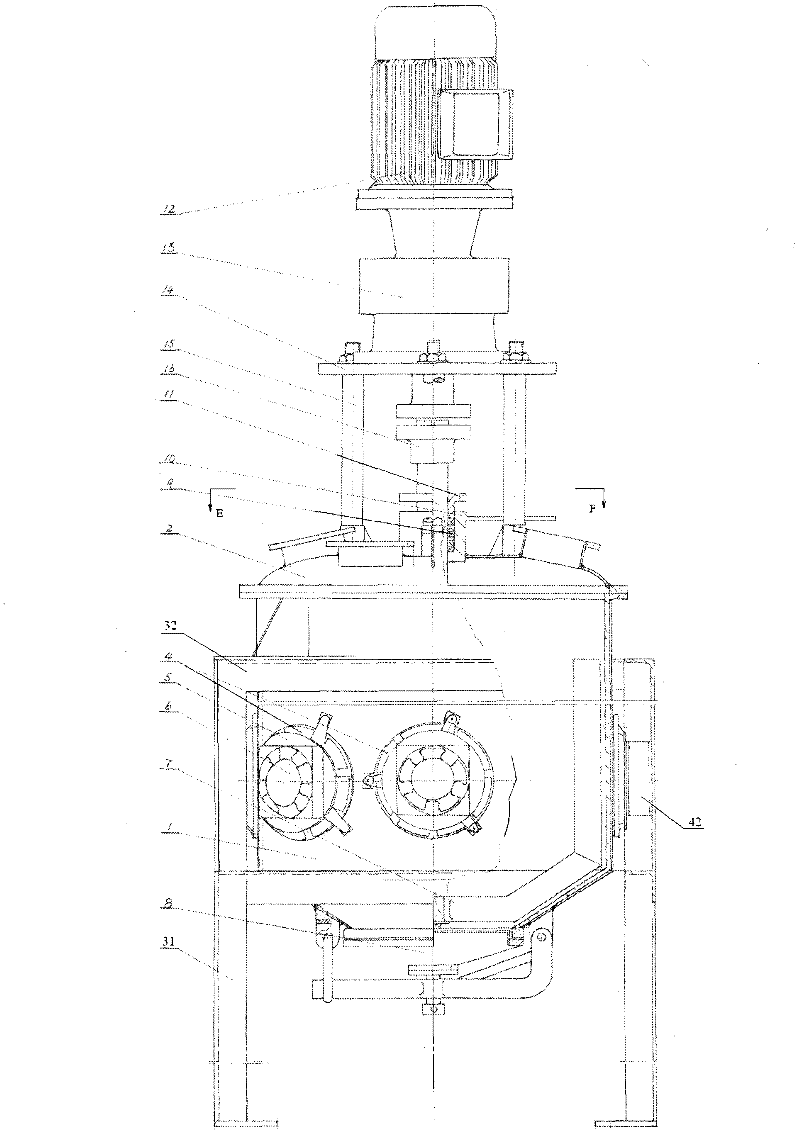

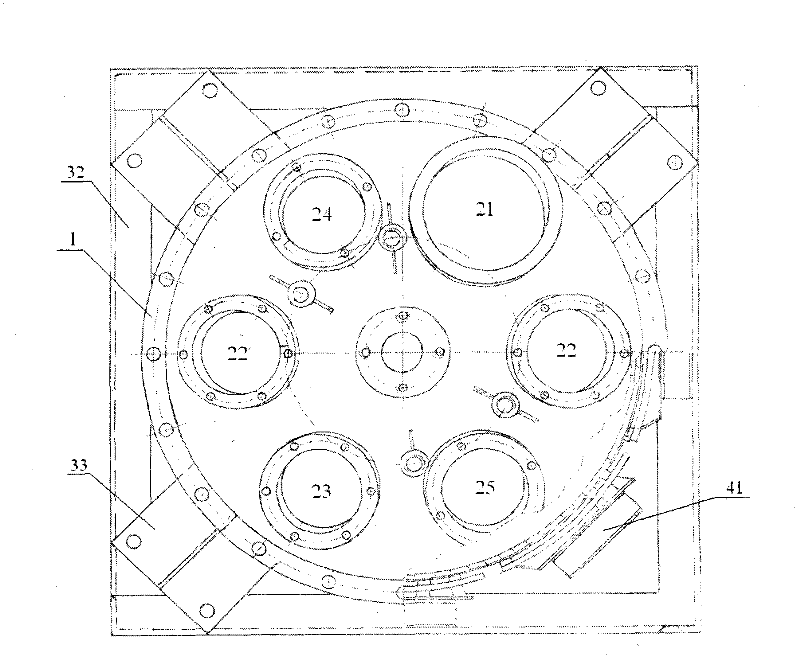

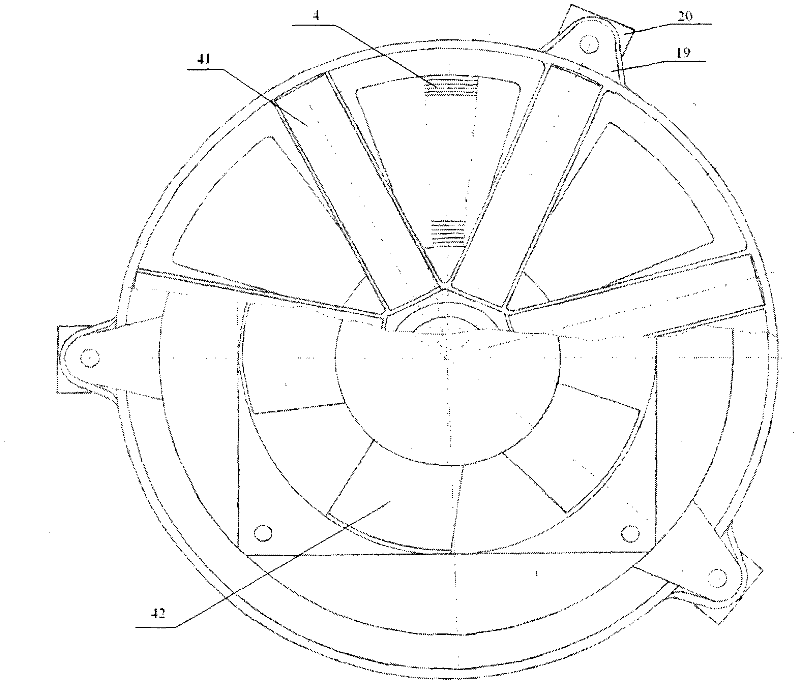

[0024] figure 1 It is a schematic diagram of the structure of the reaction kettle provided by the present invention, and the right part of the reaction kettle body is cut off. see figure 1 , The reactor includes a steel reactor pot body 1 and a reactor pot lid 2 placed on the top of the reactor pot body 1 . Reactor pot body 1 is supported by support 3, and support 3 comprises leg 31 and support platform 32, is provided with lug 33 roughly in the middle position of reaction kettle pot body 1, by means of lug 33 and support platform 32, reaction kettle pot body 1 Be fixed on the support 3, so that a part of the reactor pot body 1 is located above the support platform 32, and the other part is below the support platform 32, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap