Pipeline inner wall morphology and center axis straightness measuring device and method

A measurement method and technology of central axis, applied in measurement devices, optical devices, instruments, etc., can solve problems such as insufficient measurement methods, errors in measurement results, and inability to take into account functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

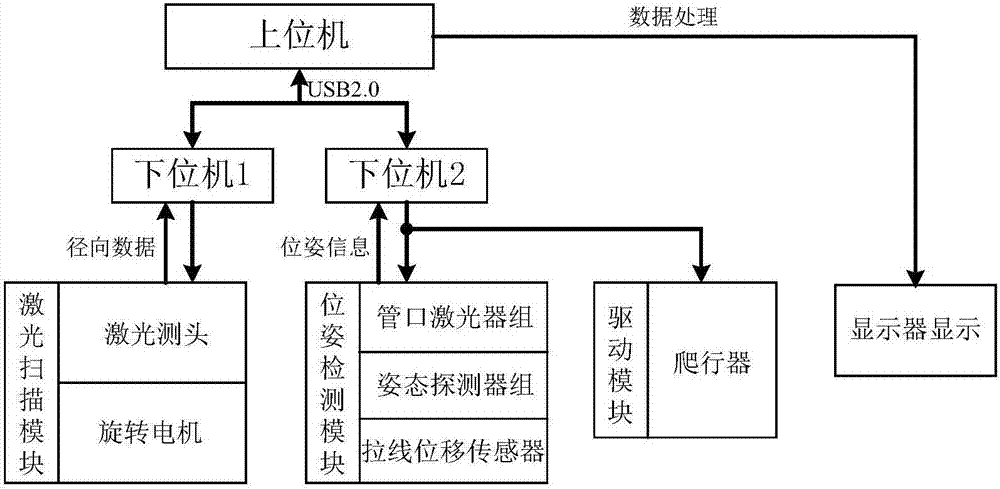

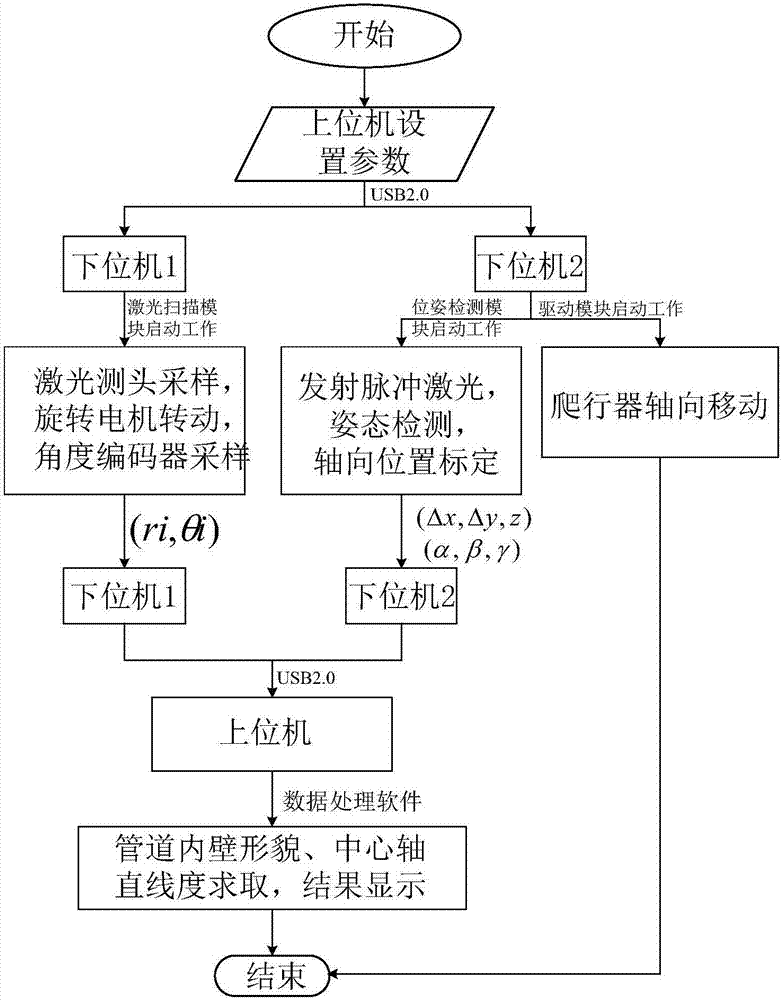

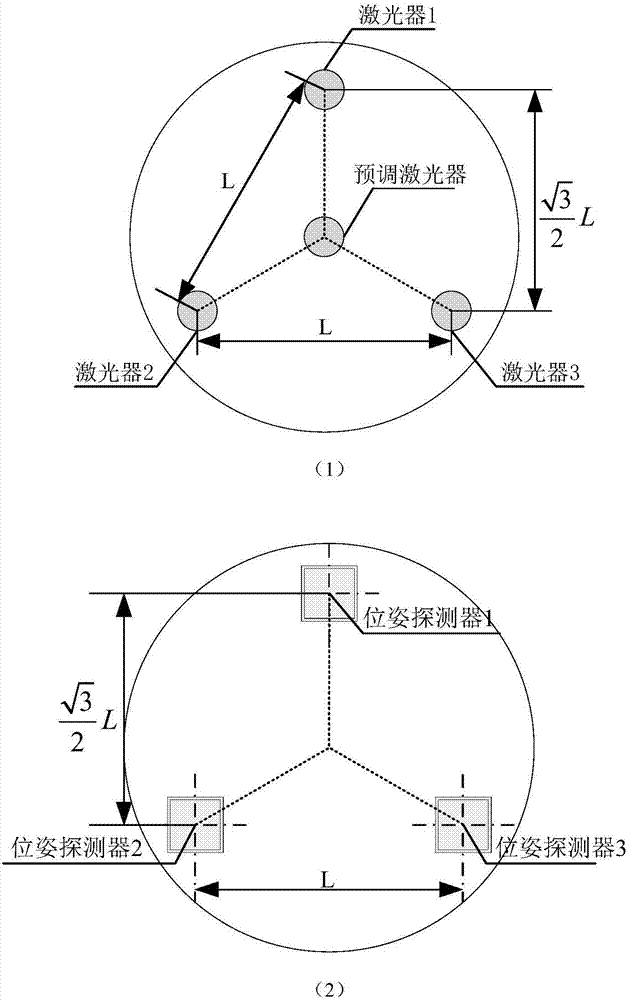

[0067] The invention relates to a method for measuring the shape of the inner wall of the pipeline and the straightness of the central axis. Before the formal measurement, a pre-adjustment device is used for pre-adjustment. The presetting device includes a laser and a target with the same size as the attitude detector. The presetting laser is exactly the same as the lasers in the laser group, and is installed at the geometric center of the laser group. It is fixed relative to other lasers and is only used for For pre-adjustment, first place the target at the mouth of the pipe, adjust the center of the target surface to the center of the pipe axis, then place the laser at an appropriate position outside the pipe so that the laser beam can enter the center of the target vertically, and then move the target to the end of the pipe. If the laser beam is normally incident on the target surface, the pre-adjustment is completed; if the laser beam misses the target, adjust the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com