Three-branch six-degrees-of-freedom low-temperature test bed of railway vehicle air spring

A technology of air springs and rail vehicles, which is applied in the field of rail vehicle testing, can solve problems such as performance testing without consideration, and achieve the effects of compact structure, light weight, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing, content of the present invention and working process thereof are described in further detail, so that those skilled in the art can implement with reference to following description:

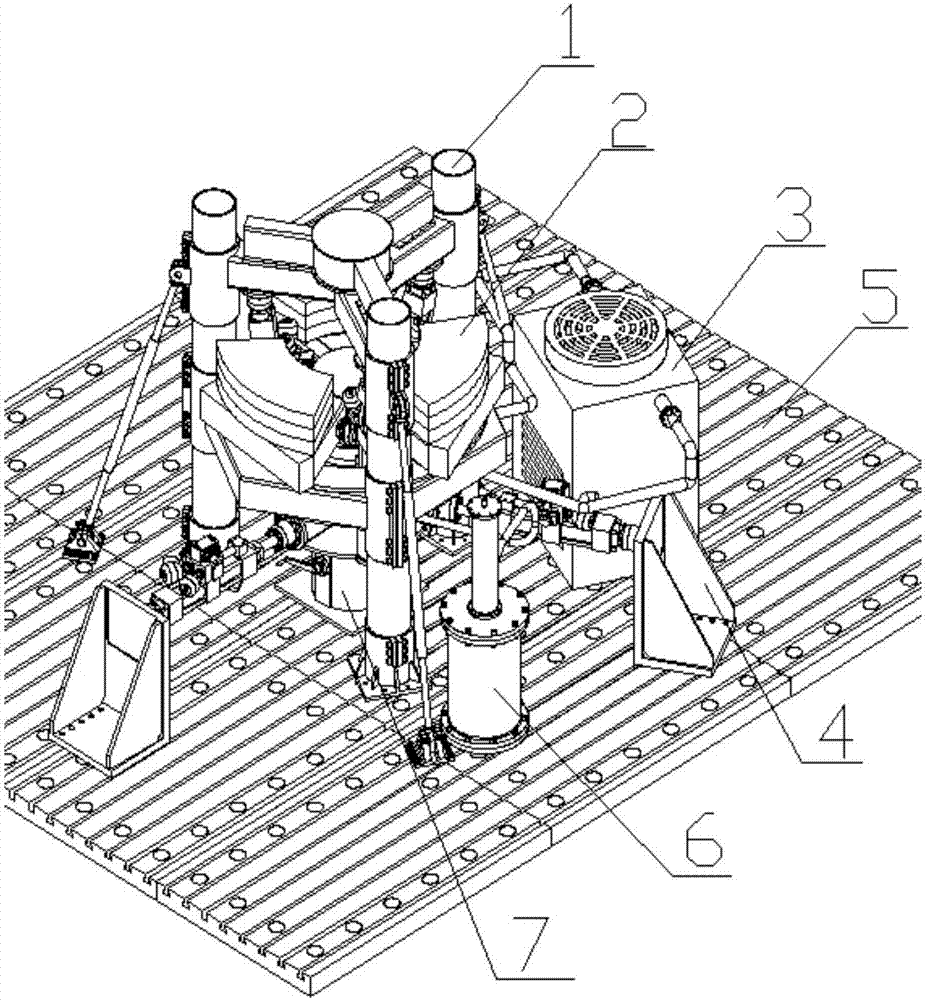

[0040] refer to figure 1 , a trifurcated six-degree-of-freedom low-temperature test bench, consisting of a trifurcated test platform 1, a loaded mass arc block 2, a refrigeration cycle system 3, a horizontal actuating mechanism 4, a T-slot foundation 5, a variable-capacity gas storage cylinder 6 and an adjustable Adjustable support upsetting 7 and other components. Among them, the T-slot foundation 5 is used as the installation basis of the entire test bench; the trifurcated test platform 1 is fixed on the T-slot foundation 5 by bolts. The load mass arc block 2 is placed on the weight trifurcated platform 11 of the trifurcated test bench platform 1, which is used to simulate the mass of the rail vehicle body; the refrigeration cycle system 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com