Bubbling detection table testing liquid recovery system

A recycling system and testing bench technology, applied in measuring devices, suspension and porous material analysis, scientific instruments, etc., can solve problems such as test liquid waste, and achieve the effect of convenient reuse, reduction of dosage, and improvement of testing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

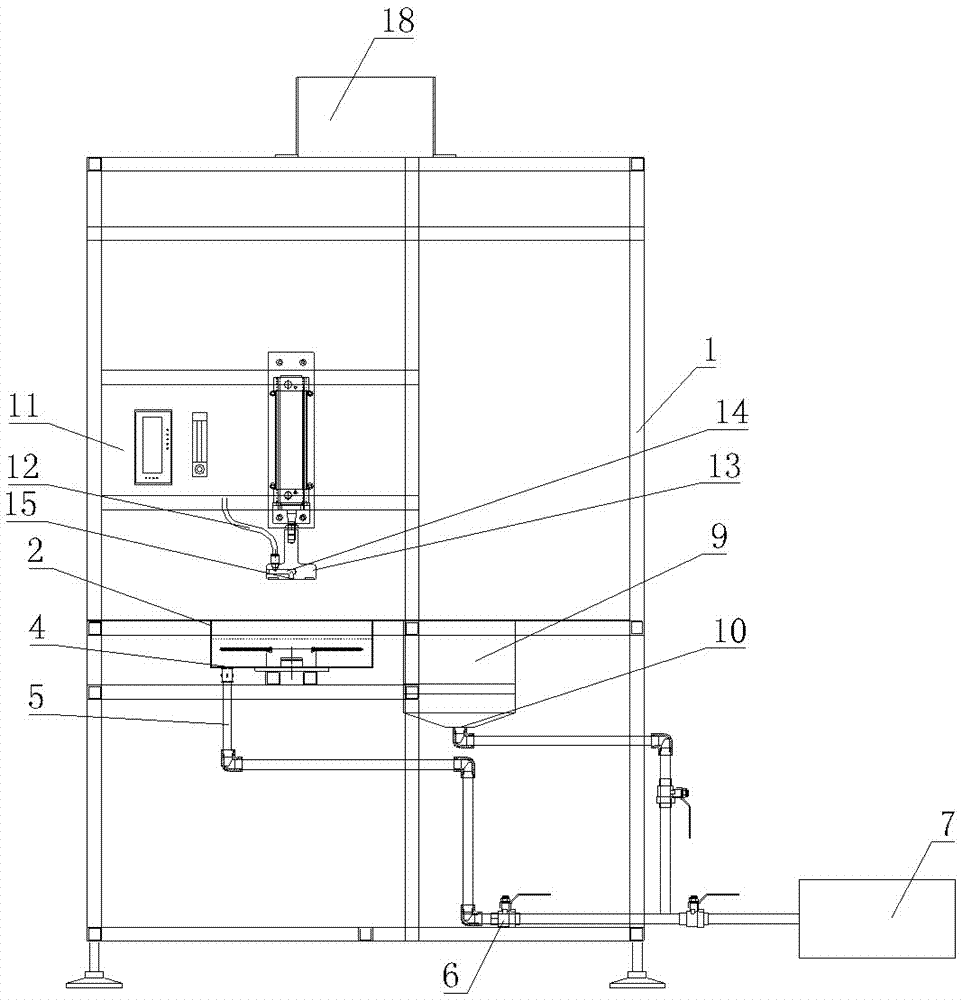

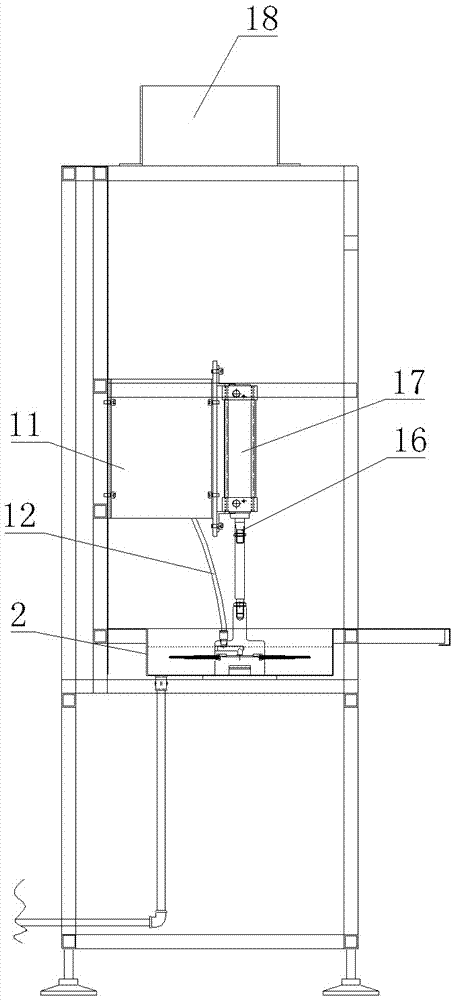

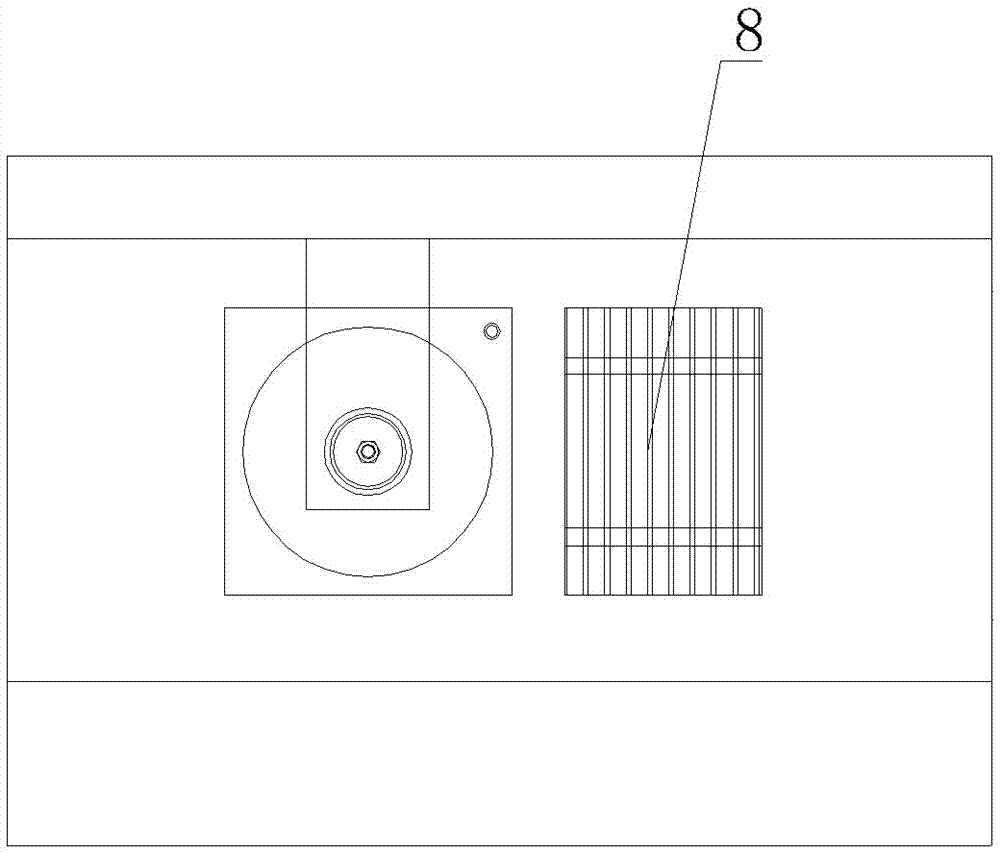

[0013] See figure 1 , figure 2 , image 3 , the recovery system of the test liquid of the bubbling detection platform of the present invention comprises a cabinet 1, the middle part of the cabinet 1 is provided with a test tank 2, the bottom of the test tank 2 is provided with a drain port 4, and the drain port 4 is connected with a drain pipe 5, A drain valve 6 is provided on the drain pipe 5, and the drain pipe 5 is connected to the collecting tank 7. In the cabinet 1, a filter rack 8 is arranged on the side corresponding to the test tank 2, and a liquid holding tank 9 is arranged at the lower end of the drain rack 8. , The bottom of the liquid storage tank 9 is provided with a liquid discharge port 10, and the liquid discharge port 10 is connected to the liquid discharge pipe 5.

[0014] An air source 11 is also provided in the cabinet 1, and the air source 11 is connected to the detection compression head 13 through the air pipeline 12. The detection compression head 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com