Molybdenum disulfide doped nano-silver particle composite humidity sensor and preparation method thereof

A nano-silver particle and humidity sensor technology, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of low response sensitivity, long response time and recovery time, humidity sensor sensitivity and response speed are difficult to further improve, and achieve high Response sensitivity, fast response speed, effect of increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

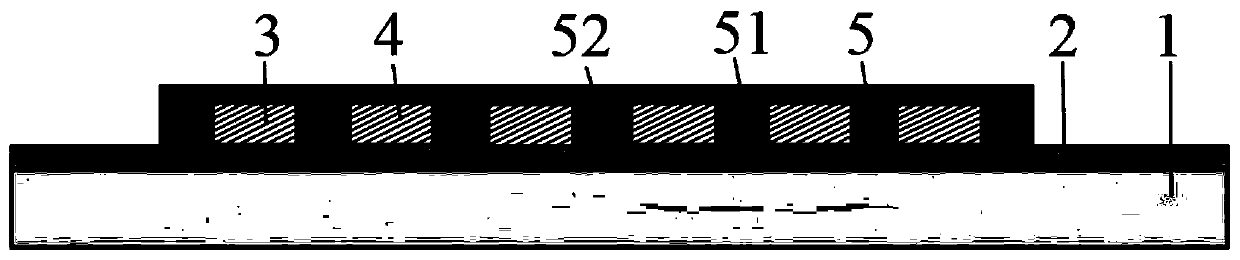

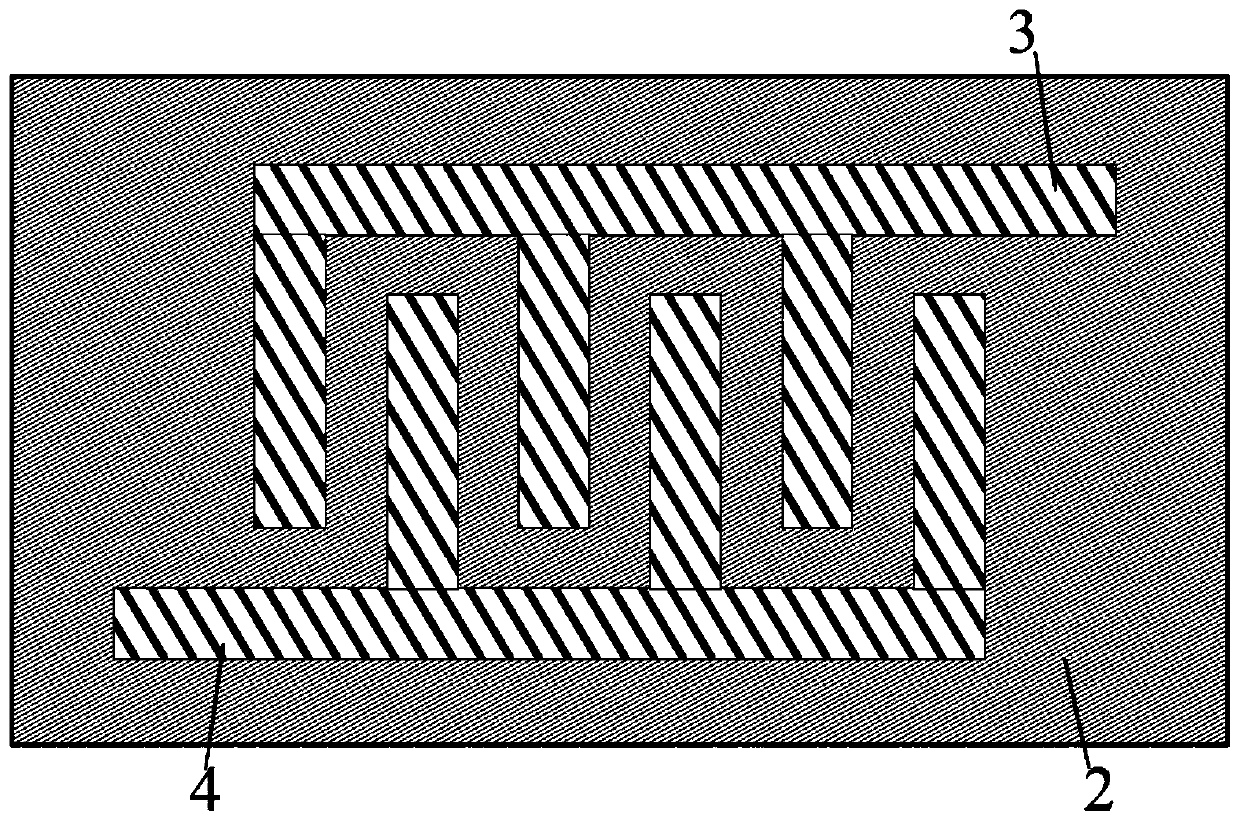

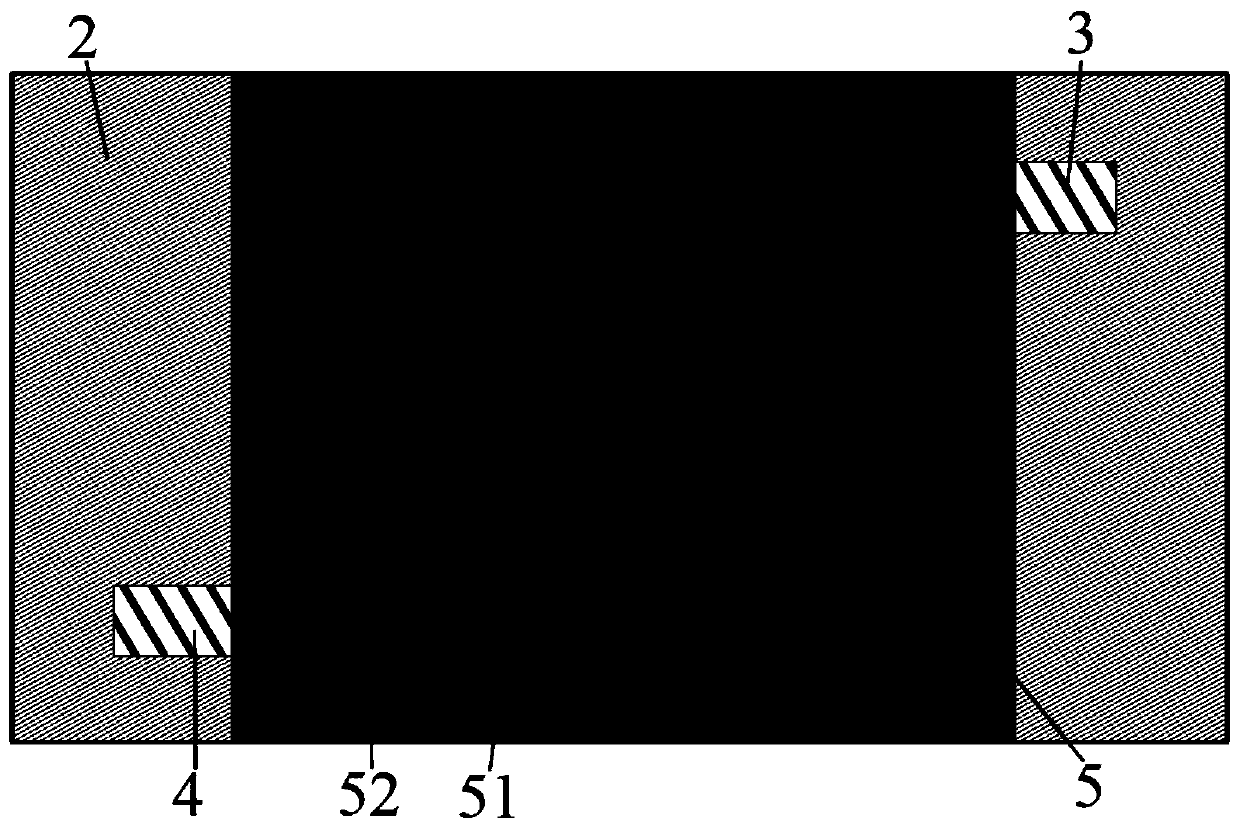

[0027] A method for preparing a molybdenum disulfide-doped nano-silver particle composite humidity sensor, comprising the following steps:

[0028] (1) the nano-silver particles with a particle diameter less than or equal to 100 nanometers are mixed into water to form a concentration of 0.1 mg / ml of nano-silver particle water dispersion, and the nano-silver particle water dispersion is mixed with a concentration of 0.1 mg / ml In the molybdenum disulfide aqueous dispersion, the volume ratios of the molybdenum disulfide aqueous dispersion and the nano-silver particle aqueous dispersion are respectively 5:1, 10:1, 15:1, and 20:1, and 4 samples are obtained. Ultrasonic dispersion for 2 hours to obtain a molybdenum disulfide-doped nano-silver particle composite material dispersion;

[0029] (2) Clean the silicon substrate, form a layer of silicon dioxide on the surface of the silicon substrate by a thermal oxidation method, and then form a first electrode and a second electrode on t...

Embodiment 2

[0038] A method for preparing a molybdenum disulfide-doped nano-silver particle composite humidity sensor, comprising the following steps:

[0039] (1) the nano-silver particles with a particle diameter less than or equal to 100 nanometers are mixed into water to form a concentration of 4.0 mg / ml of nano-silver particle water dispersion, and the nano-silver particle water dispersion is mixed with a concentration of 4.0 mg / ml In the molybdenum disulfide aqueous dispersion, the volume ratios of the molybdenum disulfide aqueous dispersion and the nano-silver particle aqueous dispersion are respectively 5:1, 10:1, 15:1, and 20:1, and 4 samples are obtained. Ultrasonic dispersion for 24 hours to obtain a molybdenum disulfide-doped nano-silver particle composite material dispersion;

[0040] (2) Clean the silicon substrate, form a layer of silicon dioxide on the surface of the silicon substrate by a thermal oxidation method, and then form a first electrode and a second electrode on ...

Embodiment 3

[0049] A method for preparing a molybdenum disulfide-doped nano-silver particle composite humidity sensor, comprising the following steps:

[0050] (1) the nano-silver particles with a particle diameter less than or equal to 100 nanometers are mixed into water to form a concentration of 2 mg / ml of nano-silver particle water dispersion, and the nano-silver particle water dispersion is mixed with a concentration of 2 mg / ml In the molybdenum disulfide aqueous dispersion, the volume ratios of the molybdenum disulfide aqueous dispersion and the nano-silver particle aqueous dispersion are respectively 5:1, 10:1, 15:1, and 20:1, and 4 samples are obtained. Ultrasonic dispersion for 13 hours to obtain a molybdenum disulfide-doped nano-silver particle composite material dispersion;

[0051] (2) Clean the silicon substrate, form a layer of silicon dioxide on the surface of the silicon substrate by a thermal oxidation method, and then form a first electrode and a second electrode on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com