Mixing apparatus and its use

一种混合装置、脊部的技术,应用在混合装置的应用领域,能够解决结构昂贵等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

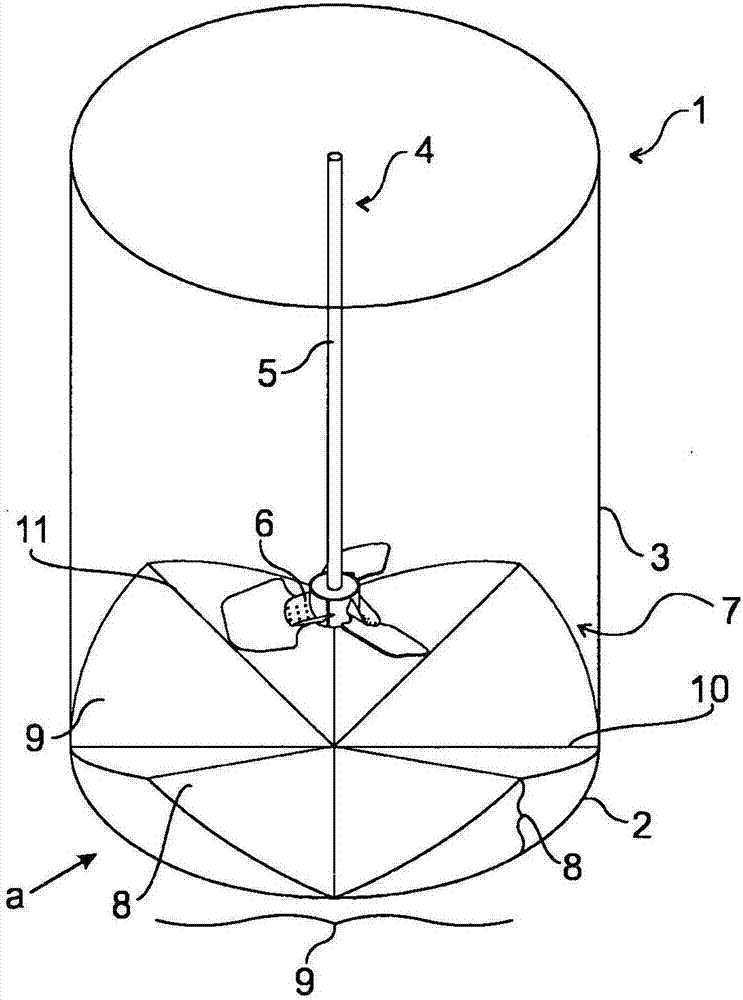

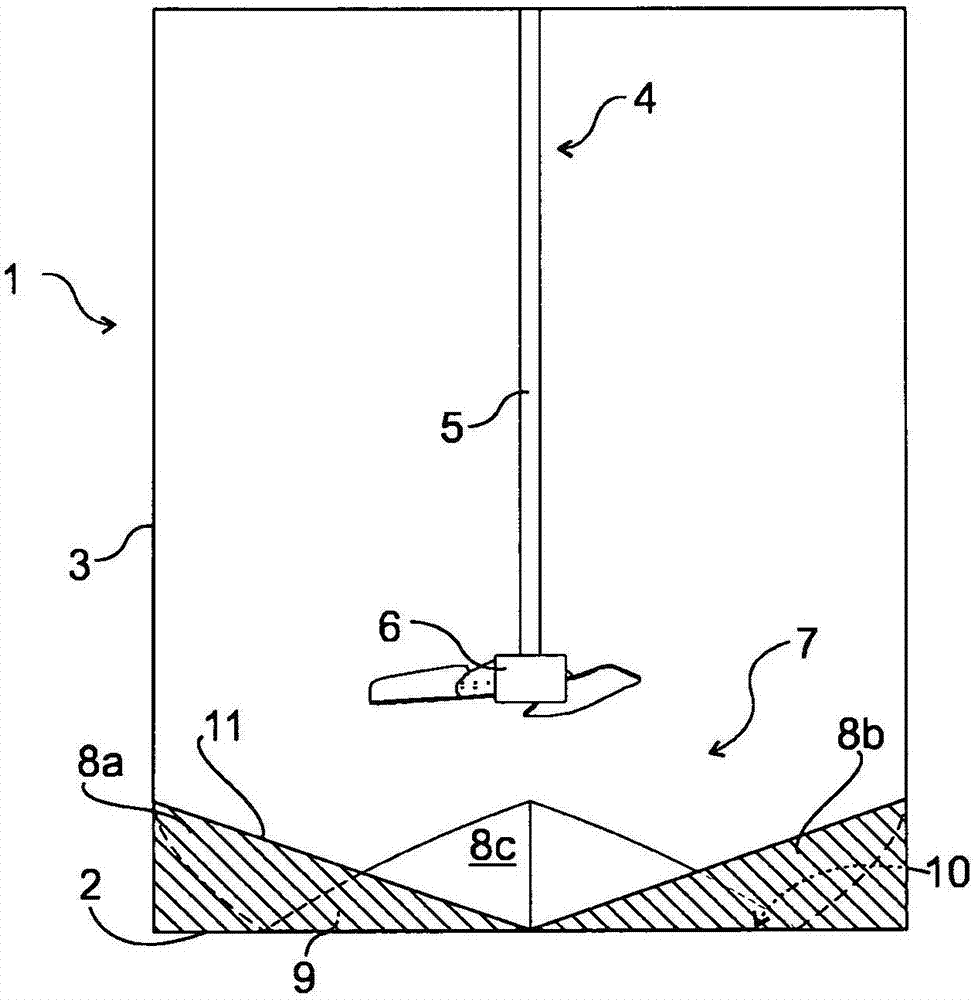

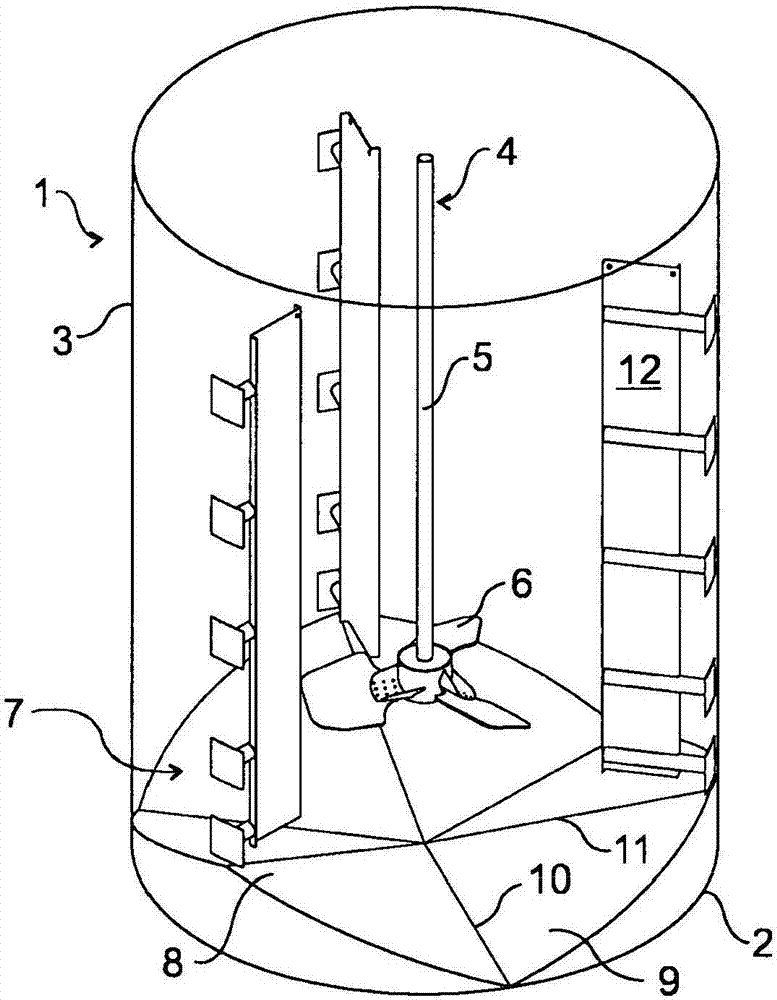

[0051] Figure 1A An exemplary embodiment of a mixing device according to the invention is shown in a side view. exist Figure 1A As well as in the remaining drawings, structural details have been omitted for clarity. The mixing device according to the invention comprises a tank 1 with a bottom 2 and walls 3 . The bottom 2 is circular and the groove 1 is a straight cylinder. The mixing device also comprises stirring means 4 with a rotating shaft 5 and an impeller 6 . exist Figure 1A Among them, the impeller 6 is a downward pumping hydrofoil impeller. The dimensions of the tank 1 and stirring means 4 may vary depending on the particular application in which the mixing device is used. At the bottom 2 of the tank 1 there is a corrugated structure 7 . The corrugated structure 7 has four ridges 8 and corresponding recesses 9 arranged such that the angle between two adjacent ridges 8 and corresponding recesses 9 is equal to all ridges 8 and corresponding recesses 9 is the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com