Replacement device for clamping and/or centering subassemblies

A technology of centering device and rotating device, applied in positioning devices, assembling machines, transportation and packaging, etc., can solve the problems of limited repeatability, adjustment cost, etc., and achieve the effect of avoiding mutual obstruction and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

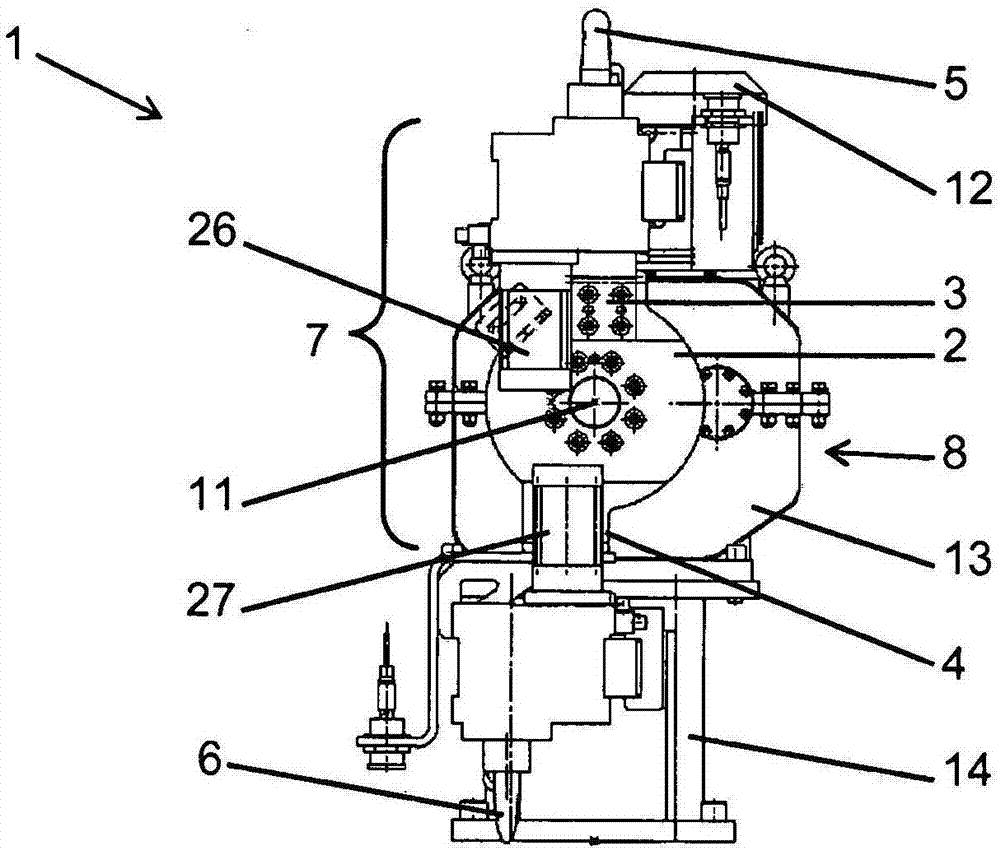

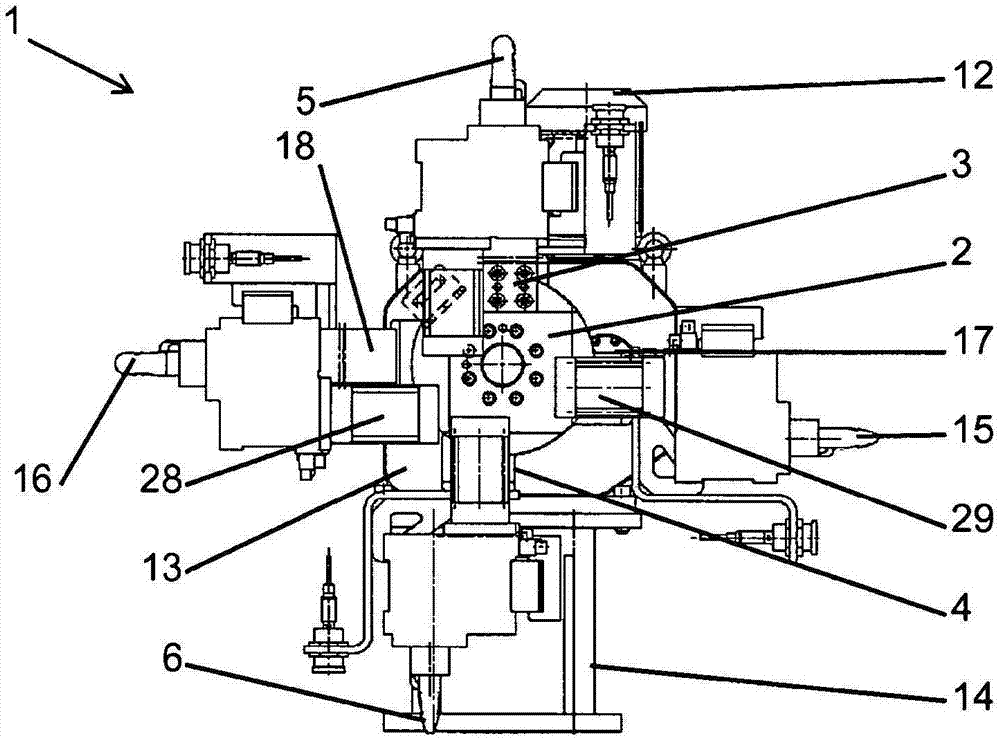

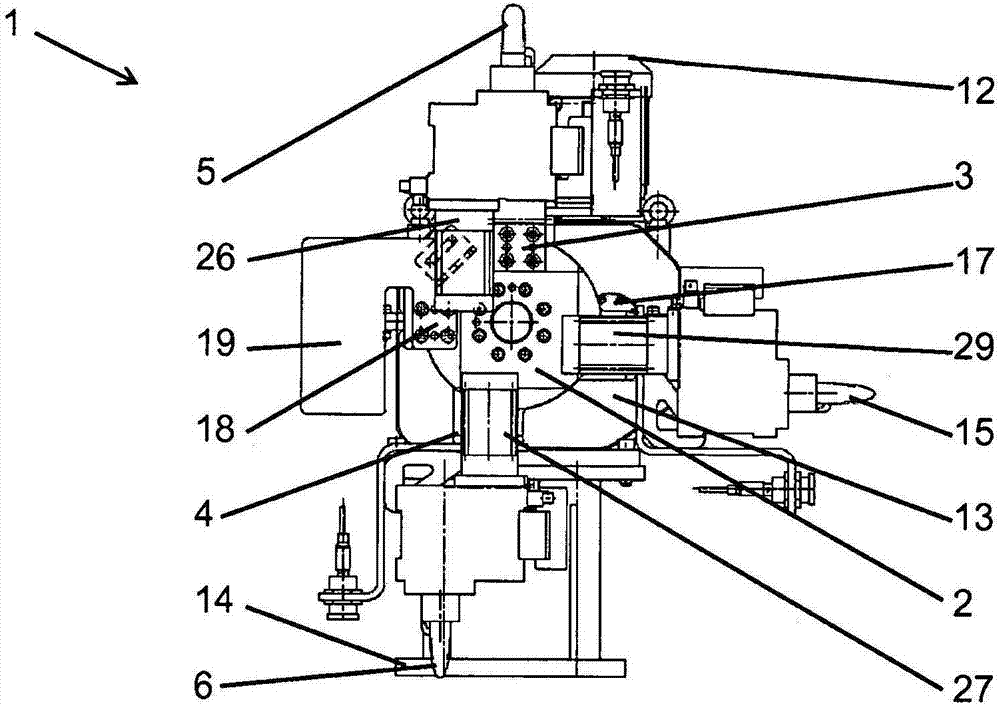

[0022] figure 1 A front view of the changing device 1 according to the invention with a changing head 2 is shown, which is rotatably mounted about a rotation axis 11. As can be seen, it relates to a change head 2 having at least two tool holders 3, 4 for accommodating at least one tool and a rotating device 7, which is included in figure 1 The Markov intermittent transmission mechanism 8 not shown in detail, wherein the tool is formed by a clamping and / or centering device 5, 6 in order to accommodate different workpieces and / or Different workpieces are positioned and constructed differently, and a rotating device 7 is provided to rotate one of the tools into a working position.

[0023] Here, the clamping and / or centering devices 5, 6 are to be understood as suitable devices which allow the positioning of corresponding workpieces, such as car body parts, or ensure that said workpieces are held in corresponding positions. Here, as the centering devices 5, 6, for example, corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com