Apparatus for spinning and winding several synthetic threads

Technology of a spinning device, thread, applied in the field of spinning and winding devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

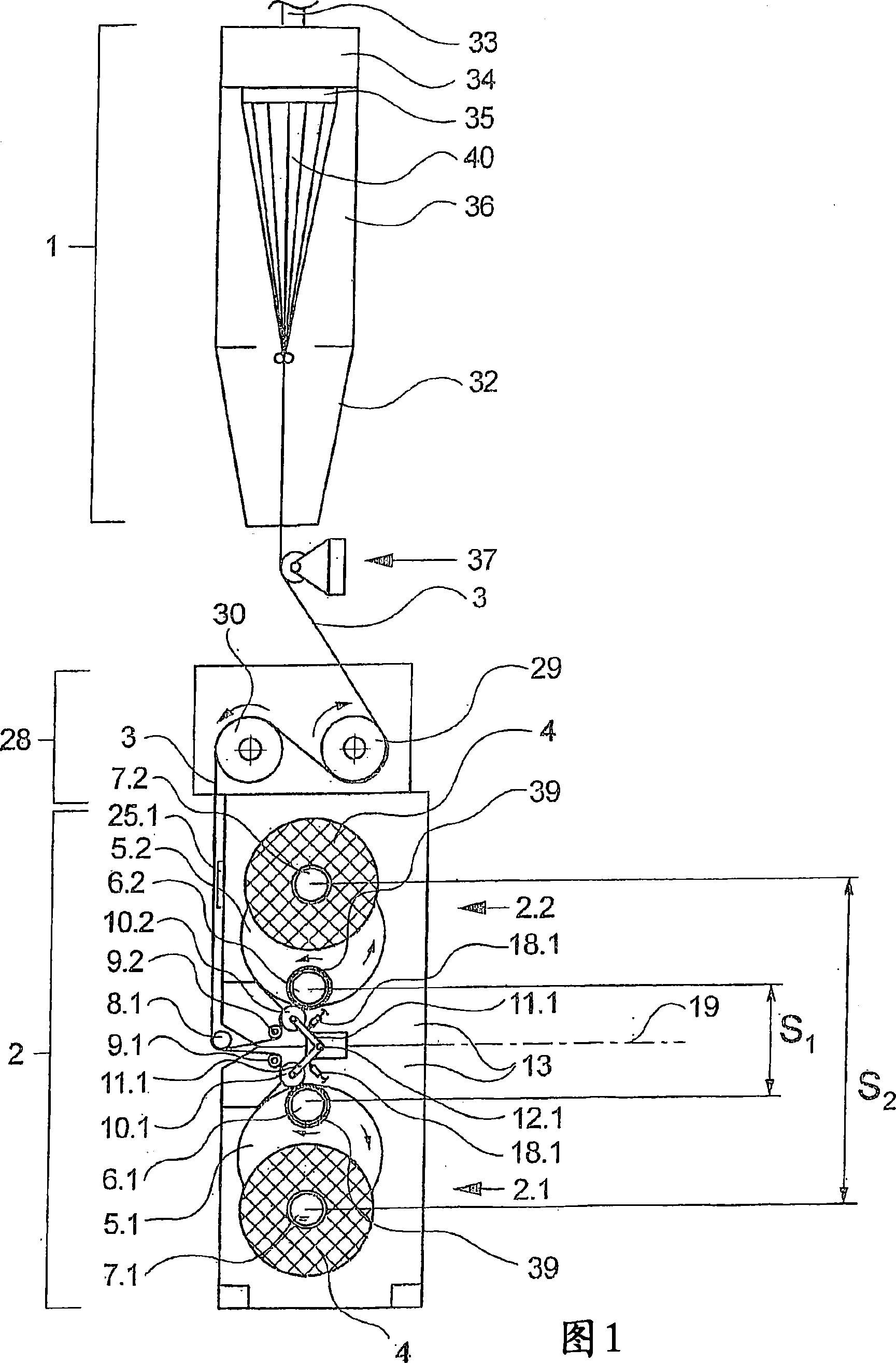

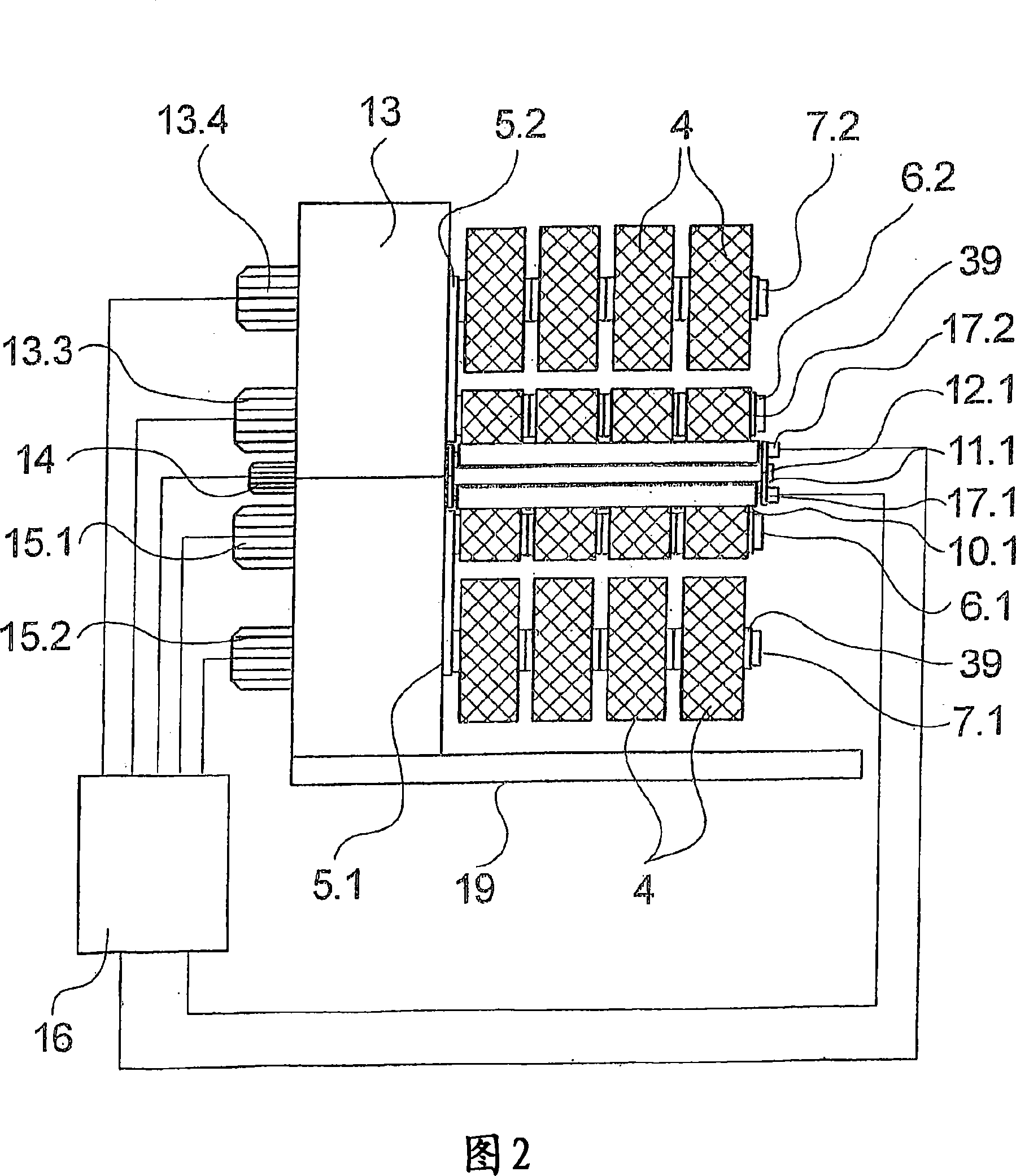

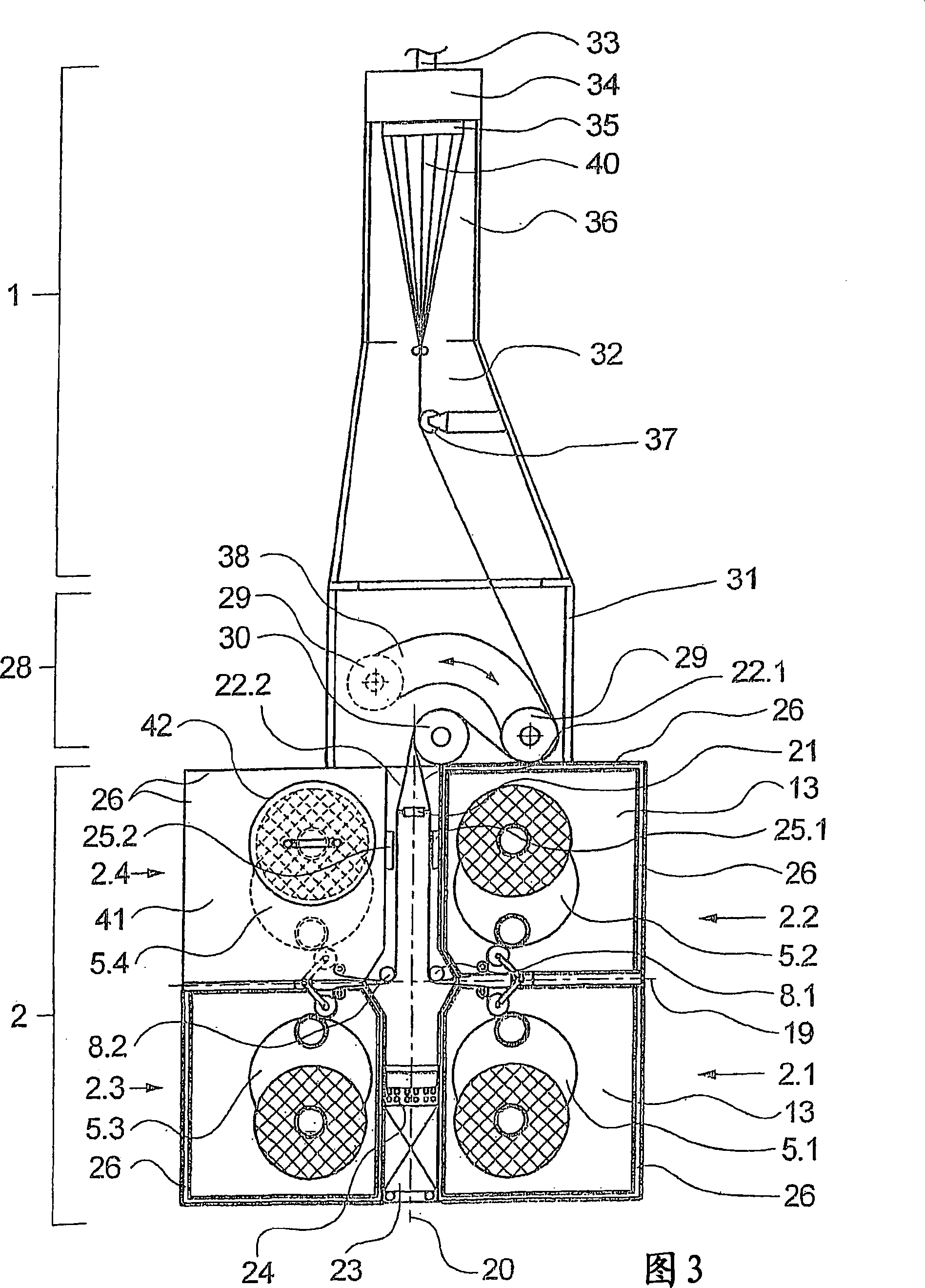

[0035] exist figure 1The middle outline shows a view of a first exemplary embodiment of the device according to the invention. The device has a spinning device 1 , a drawing device 28 arranged below the spinning device 1 and a winding unit group 2 arranged below the drawing device 28 with winding units 2 . 1 and 2 . 2 .

[0036] The spinning device 1 is connected via a melt inlet 33 to a melt source (not shown here), for example an extruder. The melt inlet 33 leads to a spinning beam 34 which has a plurality of spinnerets 35 arranged side by side, preferably arranged in a row, on its bottom side. In this exemplary embodiment, the spinnerets 35 are arranged in rows, which extend perpendicularly to the plane of the drawing. Further melt delivery components such as distributor lines and spinning pumps are generally arranged in the spin beam 34 .

[0037] A cooling tunnel 36 is formed below the spinneret 35 and is connected to a cooling air flow generator (not shown here). The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com