Corrugator

A corrugated board, factory technology, applied in the field of joining/separating components, producing corrugated board, which can solve the problems of long reorganization time, inflexibility of corrugated board factories, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

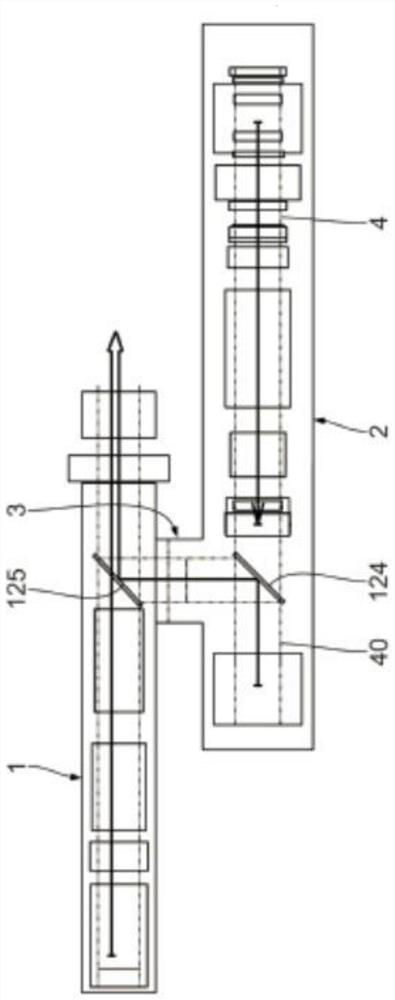

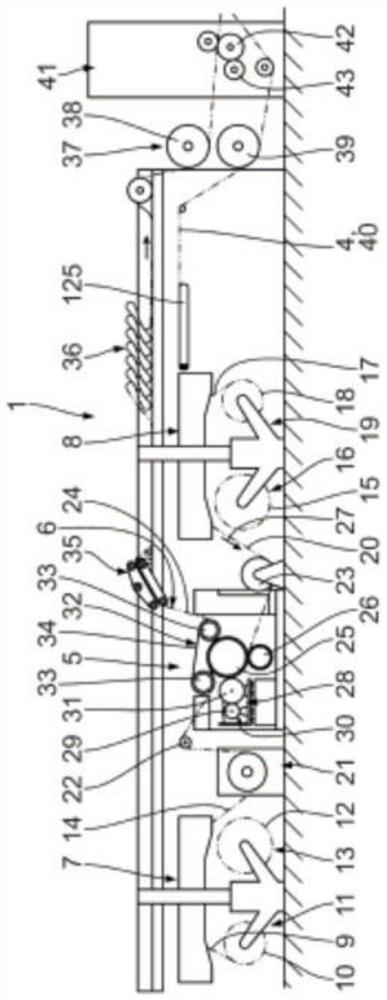

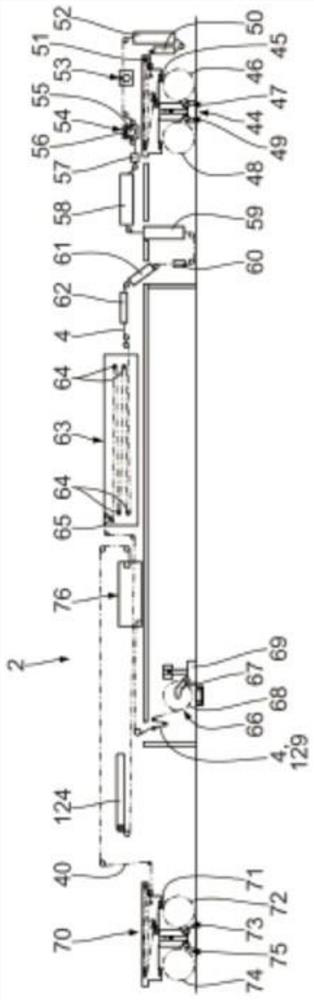

[0054] initial reference Figure 1 to Figure 3 , a corrugated board plant (not shown in its entirety) comprising a corrugated board production assembly 1 (not shown in its entirety) and a printed web / laminated web production assembly 2 and a laminated web transfer assembly 3, by means of which laminated web The transfer assembly, printing web / laminate web production assembly 2 is in particular transversely connected to the corrugated cardboard production assembly 1 . In the corrugating board production unit 1 in particular a continuous three-layer corrugated board web can be produced, while in the printing web / laminated web production unit 2 an in particular continuous laminated web 40 and / or optionally Printed printing web 4 .

[0055] Especially at figure 1 , figure 2 The corrugated cardboard production assembly 1 shown in includes a device 5 for producing a continuous corrugated cardboard web 6 which is laminated on one side.

[0056] Upstream of the device 5 for produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com