A short sausage cut flower structure

A cut flower structure and sausage technology, applied in sausage production, slaughter, food science, etc., can solve the problems of low efficiency, uneven petals, ugly, etc., and achieve the effect of fast cutting speed, simple structure and uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

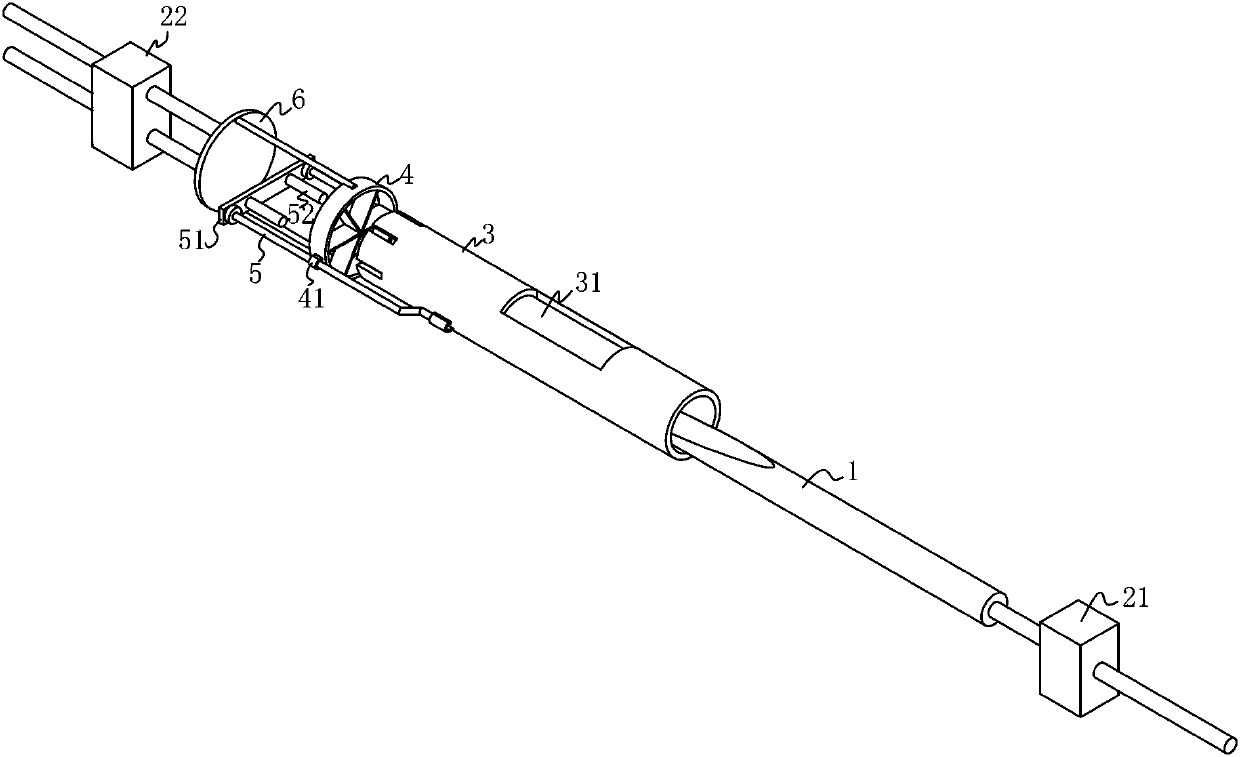

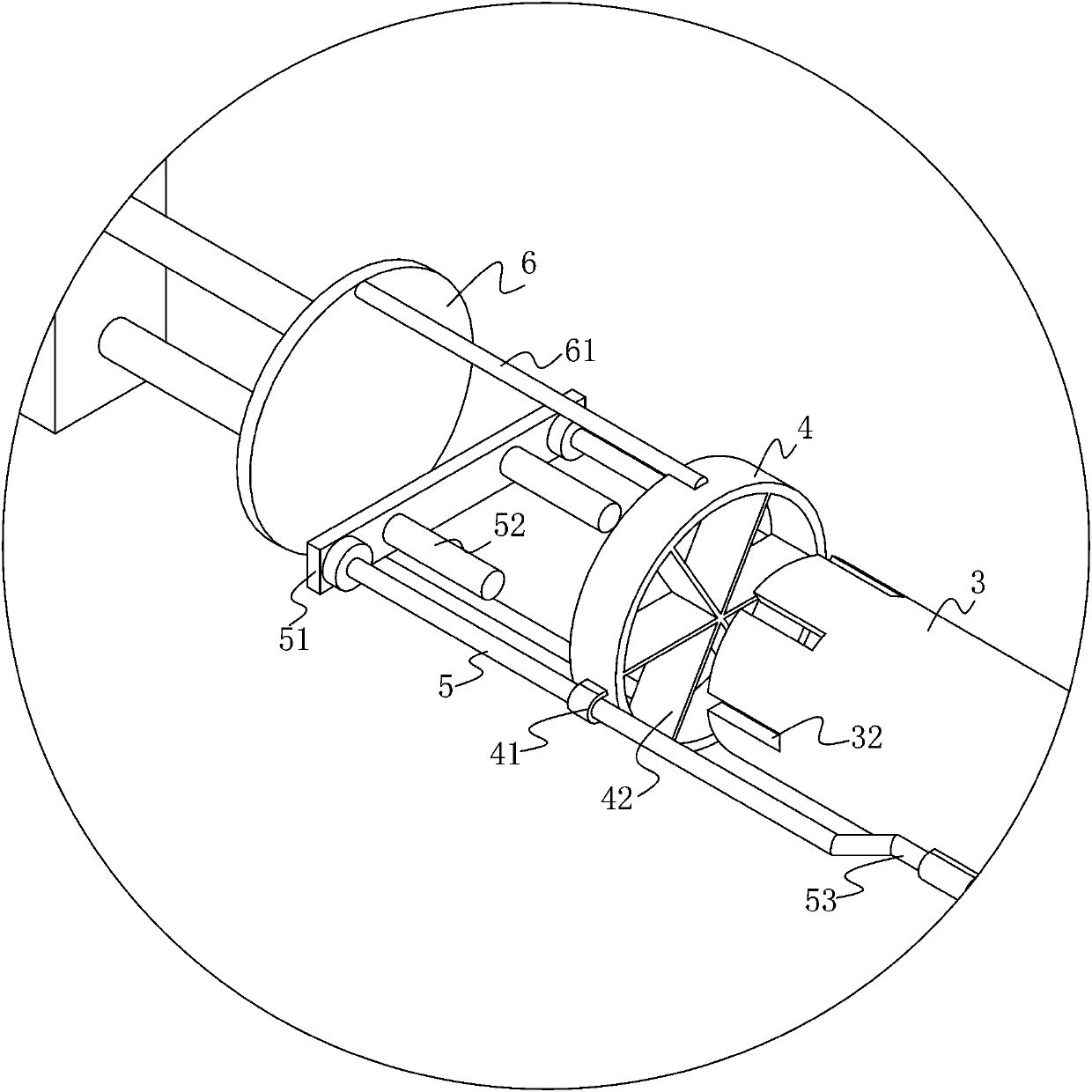

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

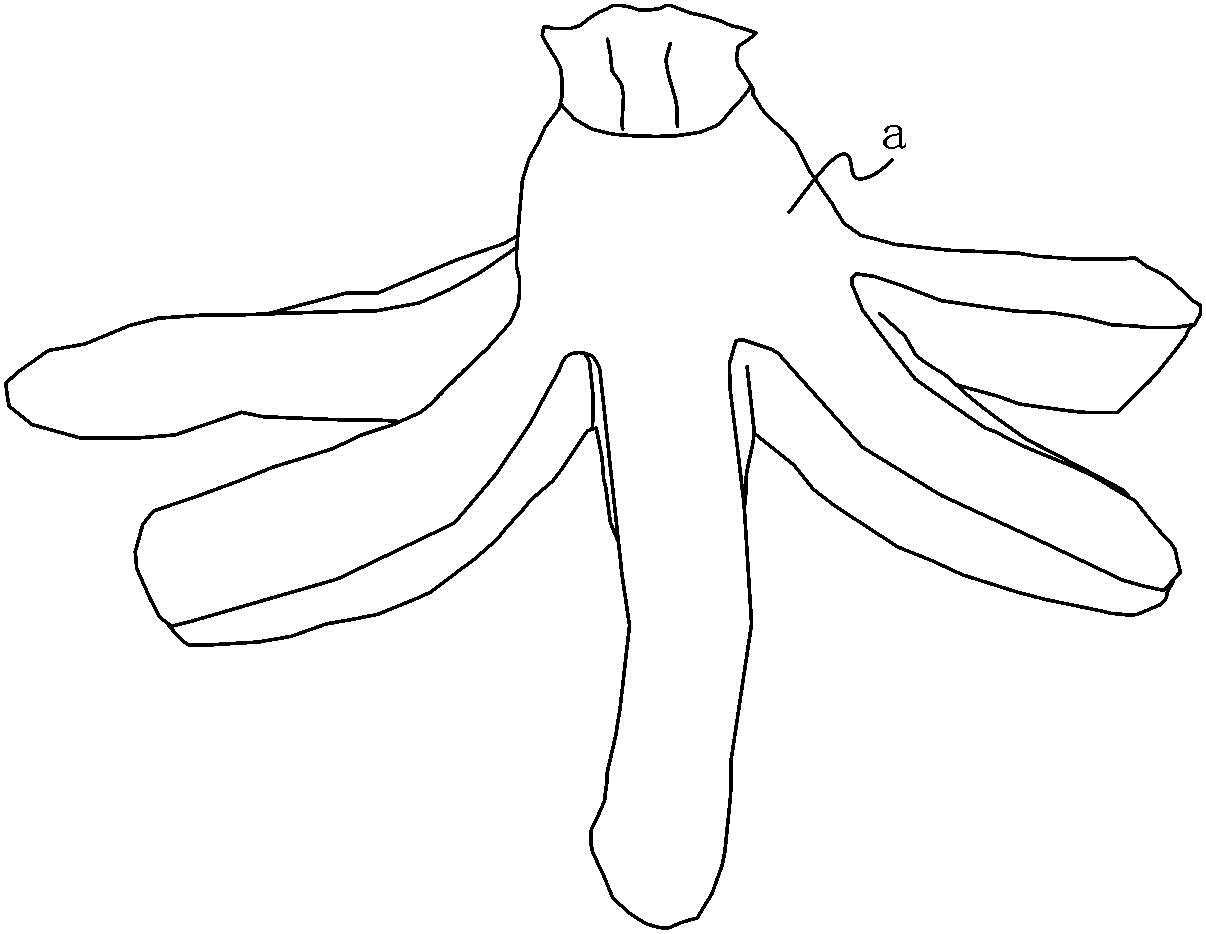

[0030] Such as Figure 1 to Figure 9 As shown, a short sausage cut flower structure described in this embodiment includes: a tube 3 with an inner diameter larger than the short sausage a, a pushing structure, and a cutter structure;

[0031] Pushing structure, the pushing structure includes a push rod 1 and a first push cylinder 21, the power output end of the first push cylinder 21 is connected with the tail end of the push rod 1, and the head end of the push rod 1 is provided with a push rod The thickness of the head 11 and the front part of the push rod 1 gradually increases from the edge connected with the push head 11 to the outer wall of the push rod 1 to form a reset slope 12, and the push head 11 is located in the tube 3;

[0032] The tube 3 is prov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap