Letter box device

A technology of equipment and mailboxes, applied in the field of mailbox equipment, can solve the problems of low production efficiency, time-consuming and laborious, complicated operation, etc., and achieve the effects of convenient operation, reduced equipment investment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

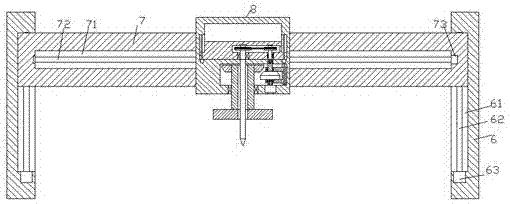

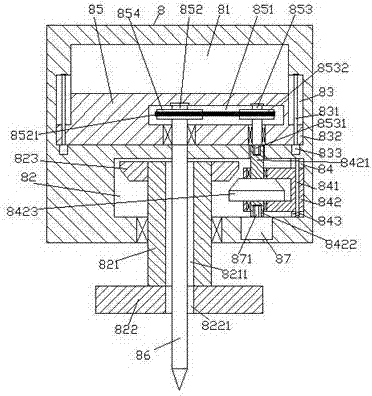

[0023] Such as Figure 1-Figure 5 As shown, a letter box device of the present invention includes a body composed of a strut 6 and a top beam 7, a manipulation assembly 8 is arranged in the body, a first hollow cavity 81 is provided in the manipulation assembly 8, and the The inner walls of the left and right sides of the first hollow cavity 81 are mutually called with a first sliding groove 83, and a first screw-shaped rod 831 is arranged in the first sliding groove 83, and the sliding fit connection in the first hollow cavity 81 is There is a first sliding block 85, a second hollow cavity 82 is provided in the manipulation assembly 8 below the first hollow cavity 81, and a guide groove 84 is provided on the right side inner wall of the second hollow cavity 82. The guide groove 84 is provided with a guide rod 841, and the guide rod 841 is slidingly fitted with a guide frame 842 that penetrates into the second hollow cavity 82 on the left side and penetrates into the second ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com