A dust cup orderly release mechanism and its vacuum cleaner

A release mechanism and dust cup technology, which is applied to vacuum cleaners, suction filters, household appliances, etc., to achieve a simple and reliable release structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

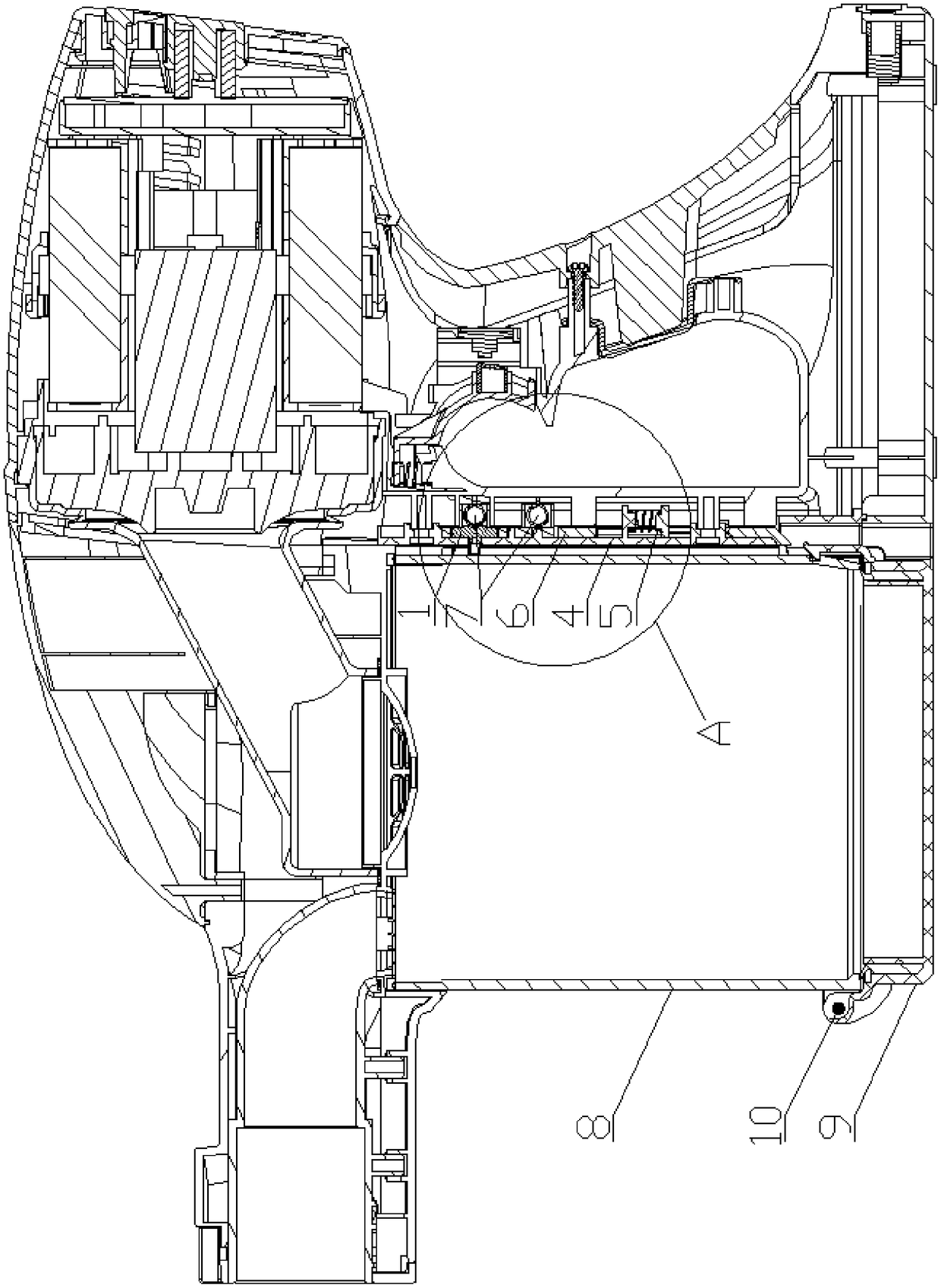

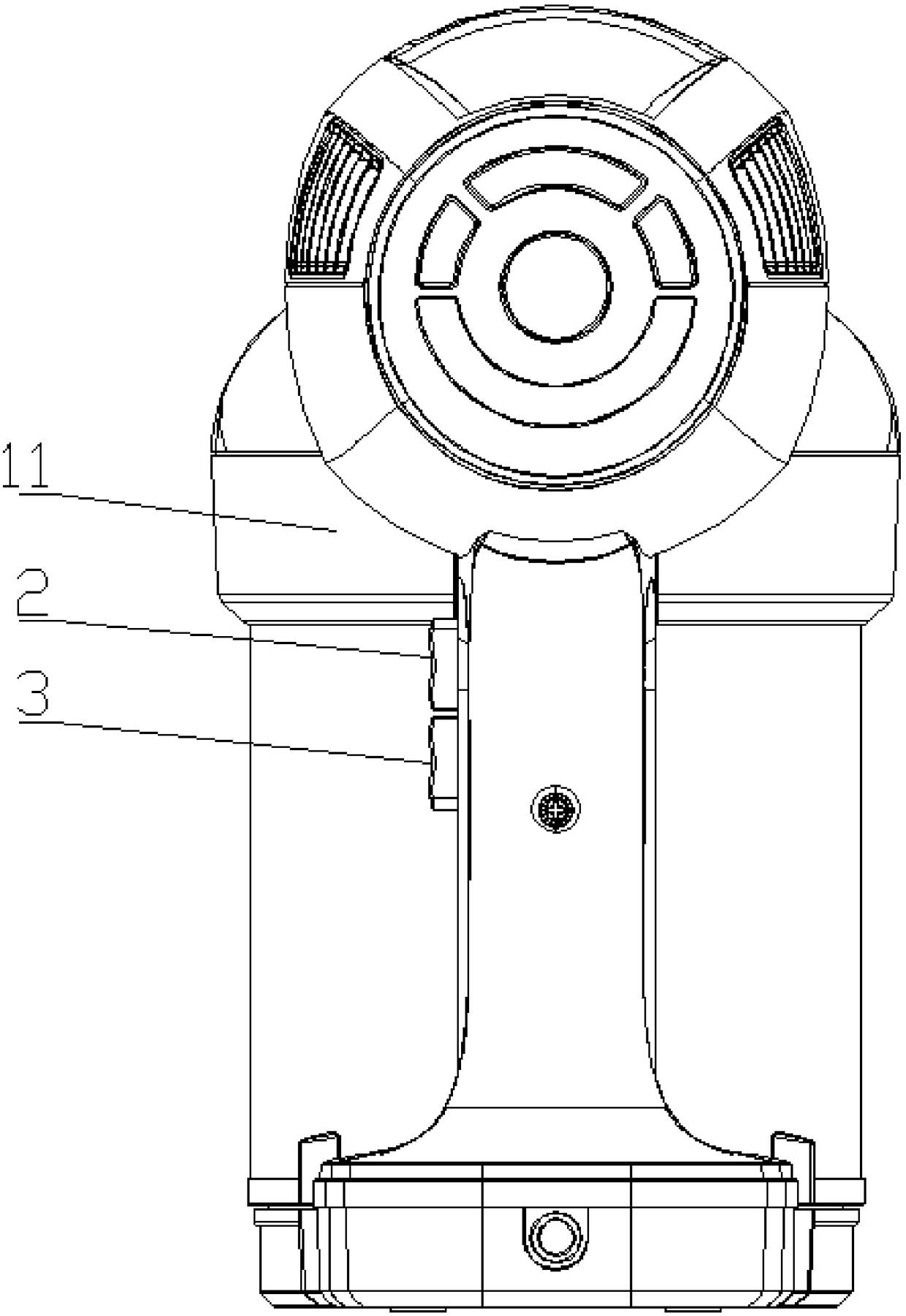

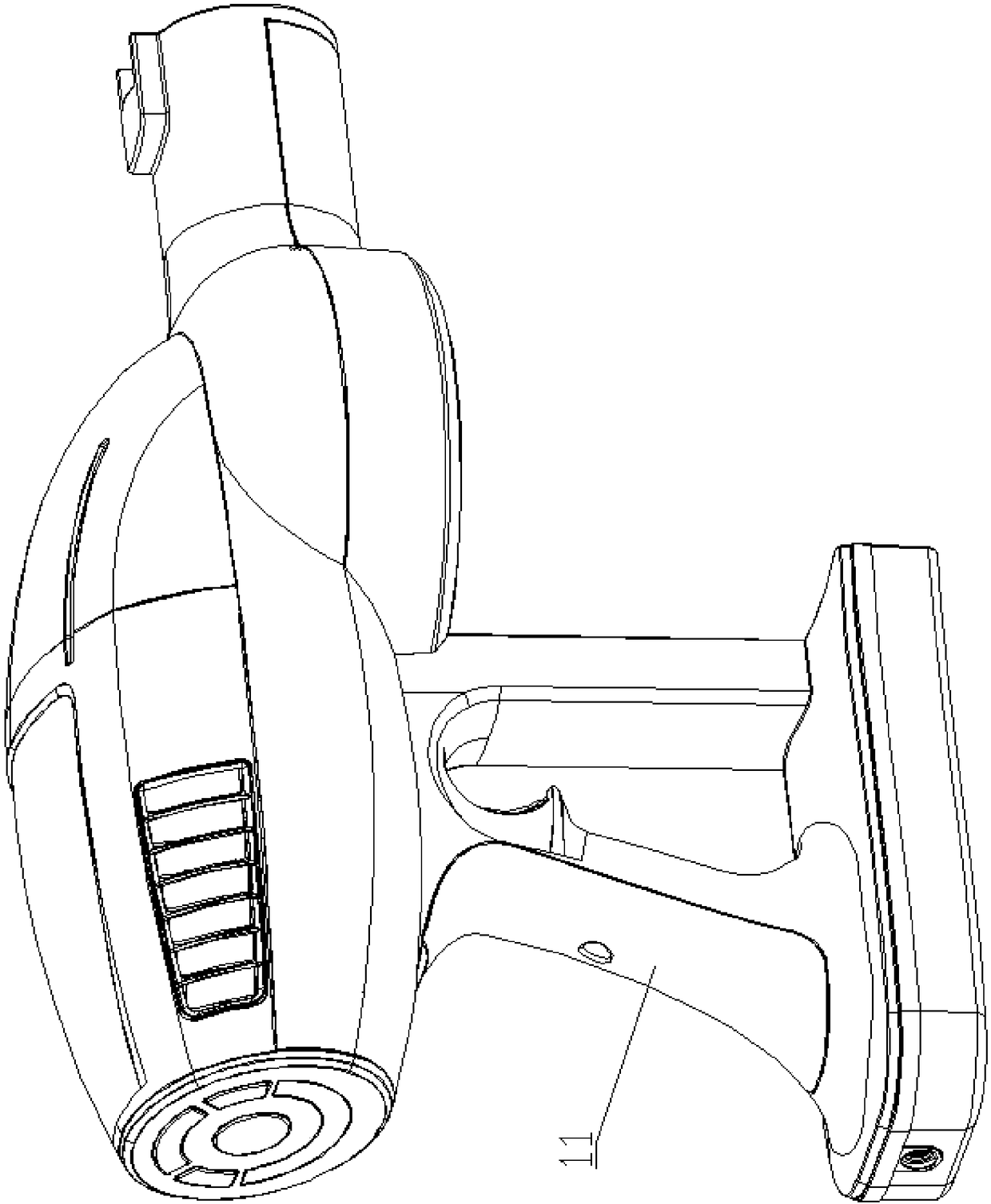

[0037] In order to achieve the purpose of the present invention, a dust cup orderly release mechanism includes: a dust cup release button 2 that controls the release of the entire dust cup 8; a dust cup cover release button 3 drives the dust cup cover release key 6 to release the dust cup cover 9; The dust cup cover release button 6 is equipped with a push rod 6a. When the dust cup cover release button 3 is not pressed, the push rod 6a is against the dust cup release button 2, and the dust cup release button 2 is restricted from releasing the entire dust cup 8. When the release button 3 is pressed, the push rod 6a is separated from the dust cup release button 2, and the restriction on the dust cup release button 2 is released.

[0038] The beneficial effect of adopting the above technical solution is: when the dust cup is installed in the fuselage, the eject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com