Stirring device for yoghourt production

A stirring device, technology of yogurt, applied in the direction of a mixer with a rotating stirring device, mixer accessories, transportation and packaging

Inactive Publication Date: 2017-08-22

上海正邻机电自动化设备有限公司

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Yogurt needs to be stirred after fermentation, but most of the equipment now only has the function of stirring

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0018] Embodiment 2: The effect of stirring yogurt can also be achieved by replacing the stirring blade with a folded stirring rod, and the other structures are the same as in Embodiment 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

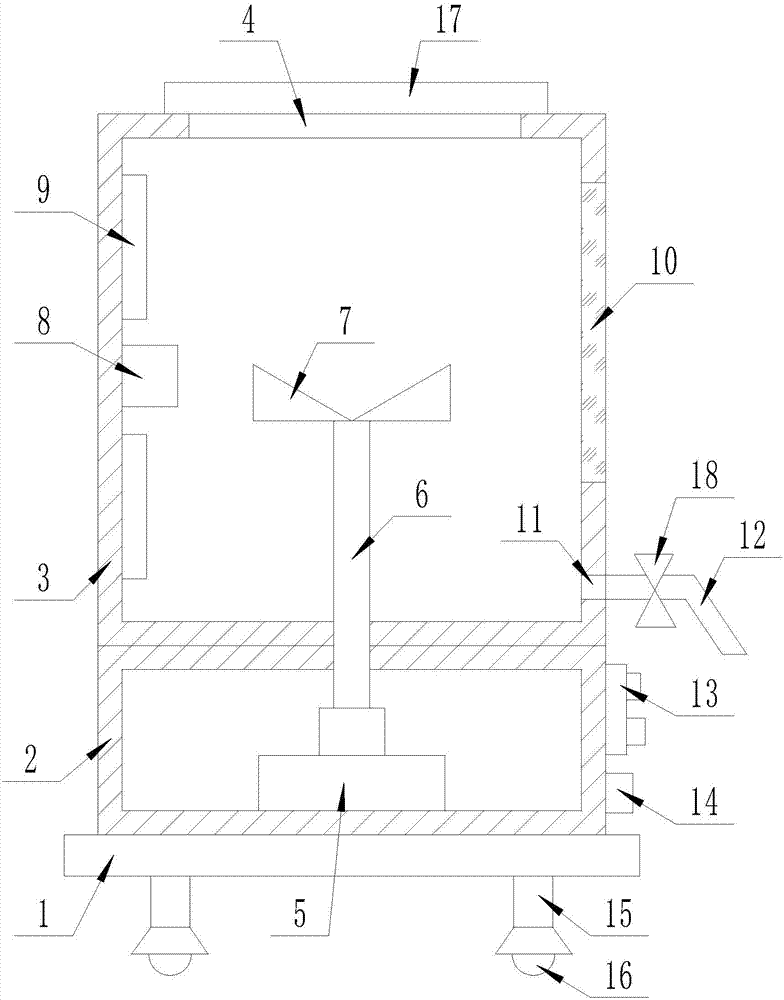

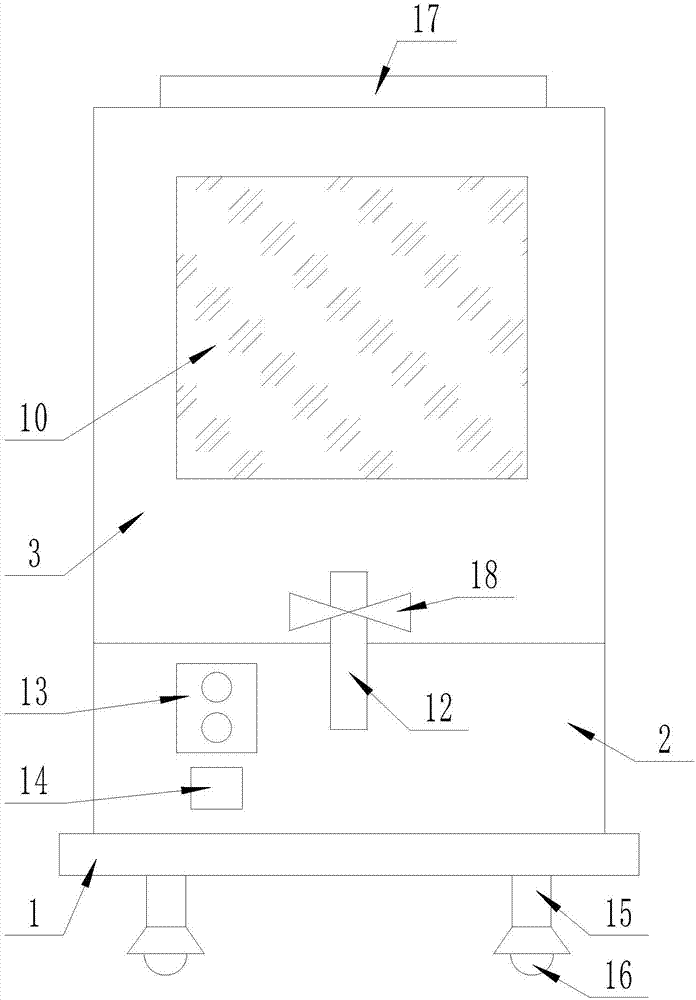

The invention discloses a stirring device for yoghourt production. The stirring device comprises a rectangular base, wherein a rectangular control box body is arranged on the upper surface of the rectangular base; a yoghourt bearing barrel is arranged on the upper surface of the rectangular control box body; a rectangular opening is formed in the upper surface of the yoghourt bearing barrel; a rotating motor of which a rotating end is upward is arranged at the center of the lower surface in the rectangular control box body; a rotating shaft which passes through the upper surface of the rectangular control box body and the lower surface of the yoghourt bearing barrel and extends into the yoghourt bearing barrel at the same time is arranged at the rotating end of the rotating motor; a stirring blade is arranged at the upper end of the rotating shaft; a waterproof temperature sensor and a group of heating sheets are arranged on the left side surface in the yoghourt bearing barrel; an observation opening is formed in the right side surface of the yoghourt bearing barrel; and sealed transparent glass is embedded into the observation opening. The stirring device has the beneficial effects that the fermented yoghourt can be fully stirred in the producing and processing process of the yoghourt, and an appropriate temperature can be controlled.

Description

technical field [0001] The invention relates to the field of yogurt processing, in particular to a stirring device for yogurt production. Background technique [0002] Yogurt is a kind of donkey milk product that uses donkey milk as raw material. After pasteurization, beneficial bacteria (starter) are added to donkey milk, and after fermentation, it is cooled and filled. [0003] The production process of yogurt can be summarized as ingredients, preheating, homogenization, sterilization, cooling, inoculation, filling, fermentation, stirring, packaging and post-ripening procedures. [0004] Yogurt needs to be stirred after fermentation, but most of the equipment now only has a stirring effect. If you can control the temperature of the yogurt at all times during the stirring process, you will produce better quality yogurt. Therefore it is necessary to design a stirring device for yoghurt production. Contents of the invention [0005] The purpose of the present invention i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01F7/18B01F15/00

CPCB01F27/90B01F35/2115B01F35/2215B01F2101/07

Inventor 田野

Owner 上海正邻机电自动化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com