Methods and systems for prediction of sensor response time

A response time and sensor technology, applied in instruments, measuring devices, machines/engines, etc., can solve problems affecting emission quality, difficulty in meeting on-board diagnostic target completion rate, underestimation of smoke and dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

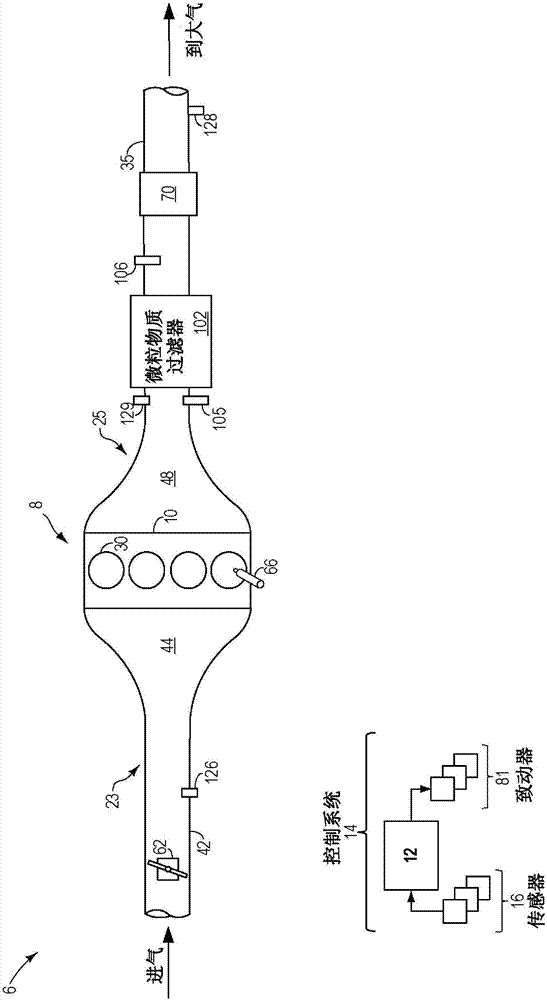

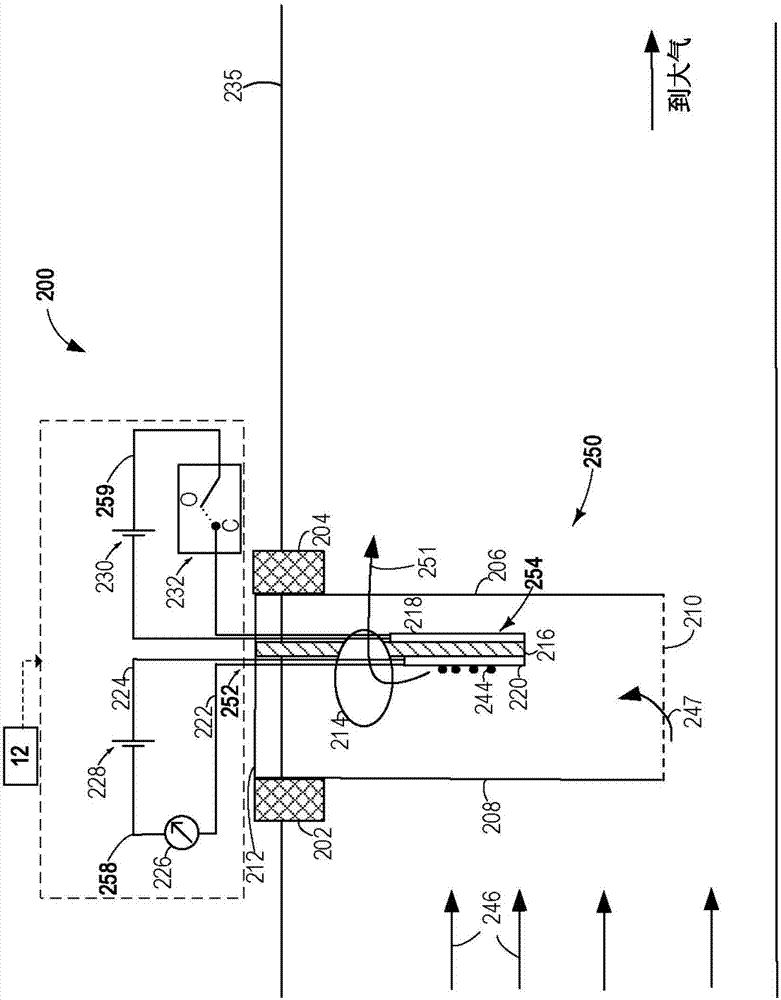

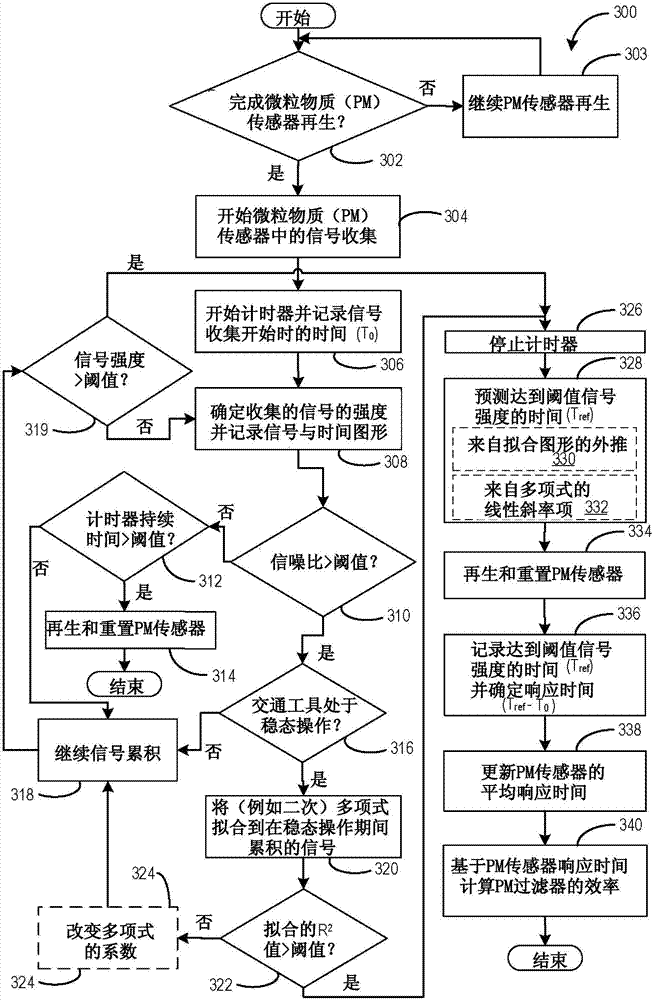

[0015] The following description relates to systems and methods for predicting the response time of a particulate matter (PM) sensor and resetting the PM sensor. In this example, the PM sensor is coupled to a figure 1 The engine system of the engine system shown. A PM sensor may be coupled to the exhaust passage upstream and / or downstream of the particulate matter filter. Due to the respiratory hazard of PM in the air, PM sensors are used to measure the concentration and / or flow of conductive soot particles in any combustion exhaust. exist figure 2 A detailed description of a PM sensor coupled to an exhaust passage is shown in . One example of the use of PM sensors in the automotive industry is for controlling or diagnosing emissions of regulated PM emissions of automobiles. The engine controller is configured to perform tasks such as image 3 A control routine of an example routine to predict the response time of the PM sensor based on the soot accumulation signal obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com