Clutch with limiting function

A clutch and centrifugal body technology, applied in the field of clutches, can solve problems such as serious power loss and unstable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

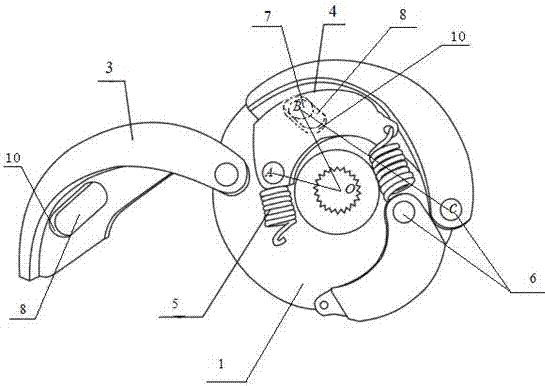

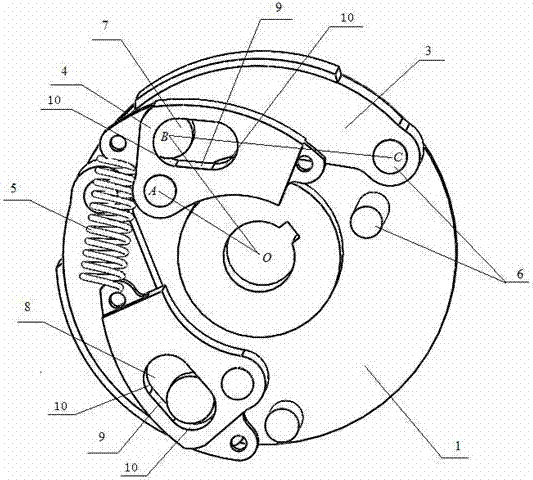

[0029] combined with figure 1 The said clutch with limit is provided with two or more groups of cylinders on the disk surface of the driving disc 1, and the roots of the cylinders are all provided with steps, and each group of cylinders includes centrifugal body positioning columns and special-shaped Lever positioning column, the centrifugal body positioning column is close to the edge, and the special-shaped lever positioning column is arranged on the inner side of the centrifugal body positioning column; one end of the centrifugal body 3 is movably socketed on the centrifugal body positioning column, and the movable body of the centrifugal body 3 The other end of the shaft is provided with a concave groove 8; the bottom of the special-shaped lever 4 is provided with a protruding body 7, and the protruding body 7 enters the inside of the centrifuge body 3 concave groove 8. One end of the special-shaped lever 4 is movably socketed on the special-shaped lever positioning column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com