Large-scale process pipeline defect detection method

A technology for process pipelines and detection methods, applied in measuring devices, image enhancements, instruments, etc., can solve problems such as safety hazards, small cracks, and difficulty in detecting small cracks in pipelines, and achieve simple operation process, reduced construction costs, and detection high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

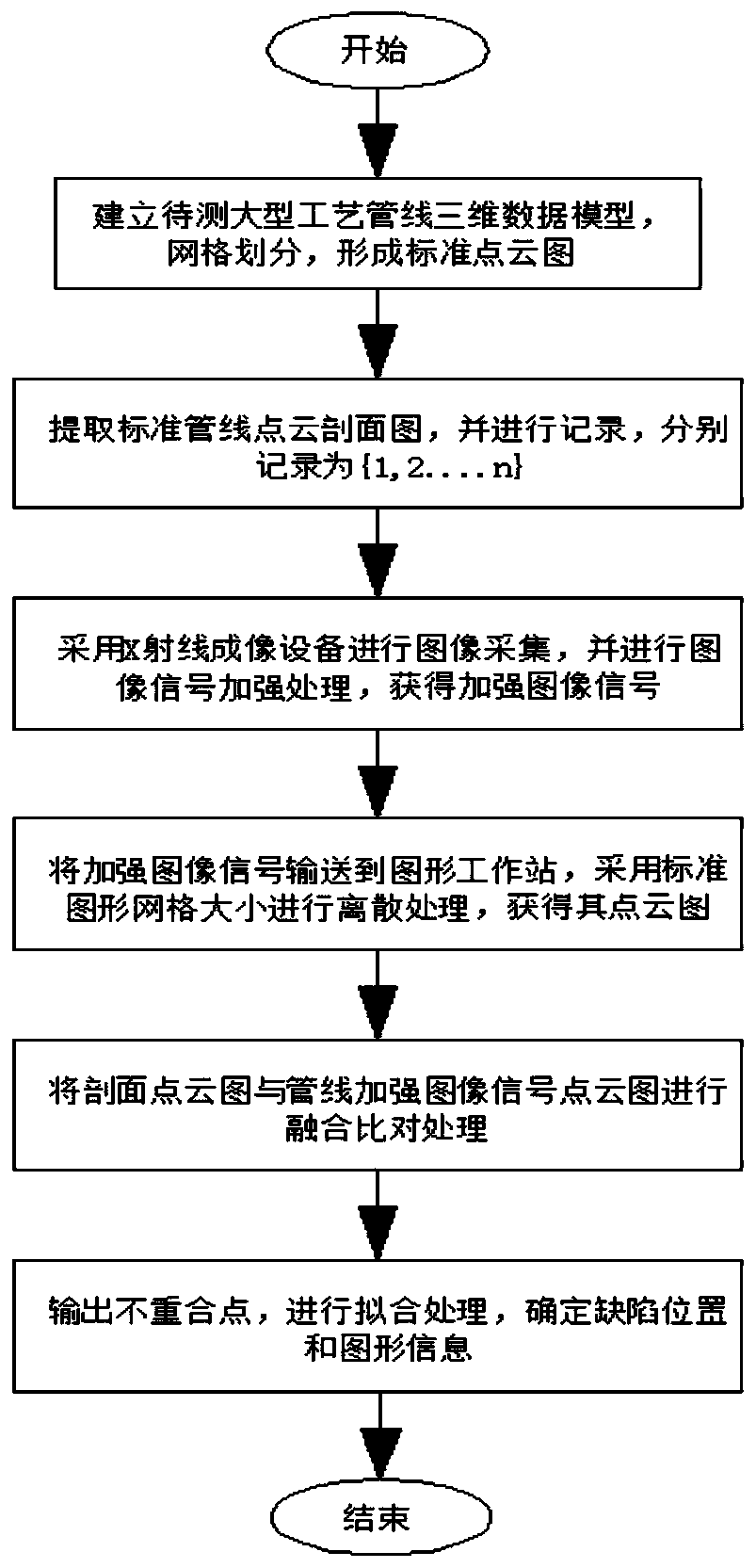

[0016] As shown in the accompanying drawings, the large-scale process pipeline defect detection method of the present invention comprises the following steps:

[0017] Step 1. Establish the 3D data model of the large-scale process pipeline to be tested and set the graphic grid size, then divide the 3D data model into grids according to the set graphic grid size, extract the grid division points, and form a standard pipeline point cloud graphics;

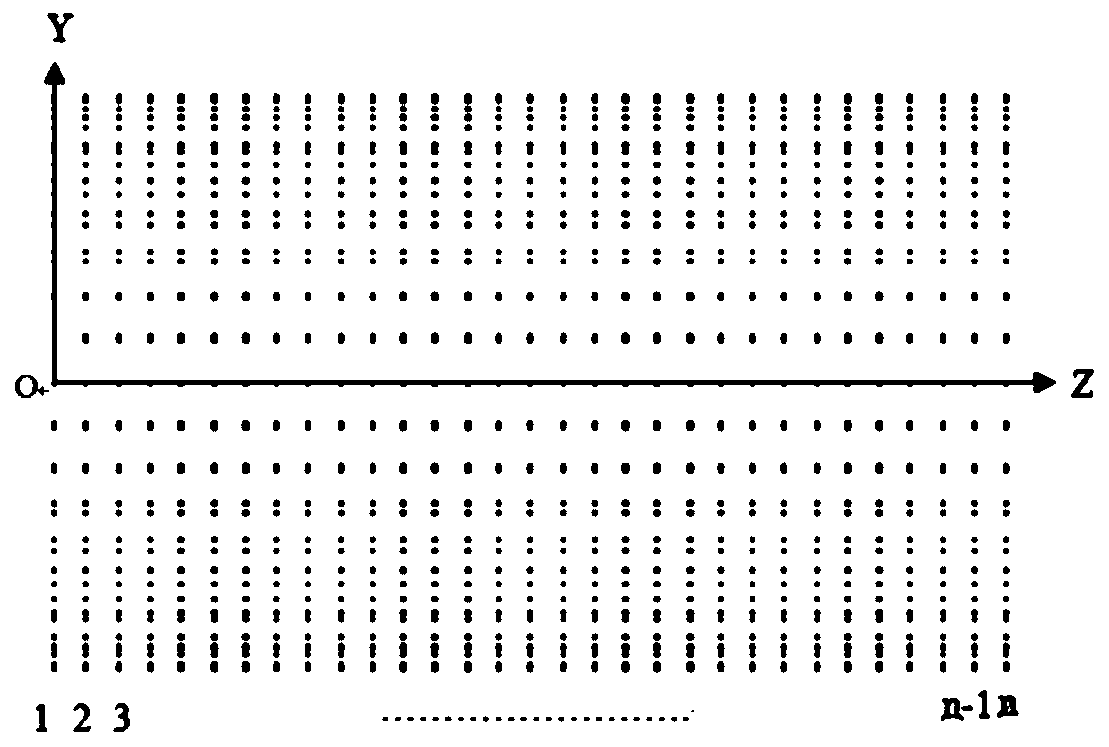

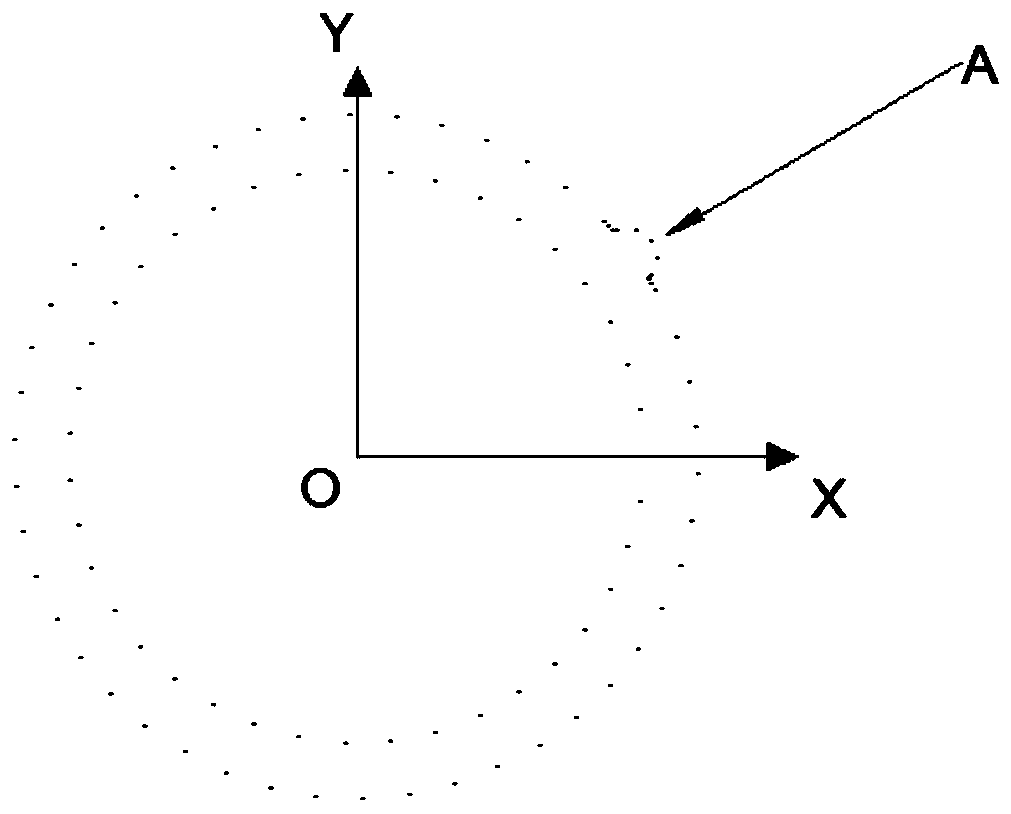

[0018] Step 2. Make multiple cross-sections along the axis perpendicular to the standard pipeline point cloud graphics, and then extract the point cloud cross-sections for recording, which are respectively recorded as {1, 2, 3...n};

[0019] Step 3, using X-ray imaging equipment to collect images of the large-scale process pipeline to be detected, and using image enhancement components to perform s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com