A Compression Molding Process Using Polymer Films to Improve the Appearance of Fiber Composites

A technology of compression molding and polymer film, applied in the field of fiber composite material molding, can solve the problems of polymer film resin can not be discharged, inconvenient operation, poor matching of polymer film resin fluidity control, etc., to save equipment and labor costs, shorten the traditional Technological process, eliminating the effect of filling soil to repair the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Ordinary carbon cloth surface

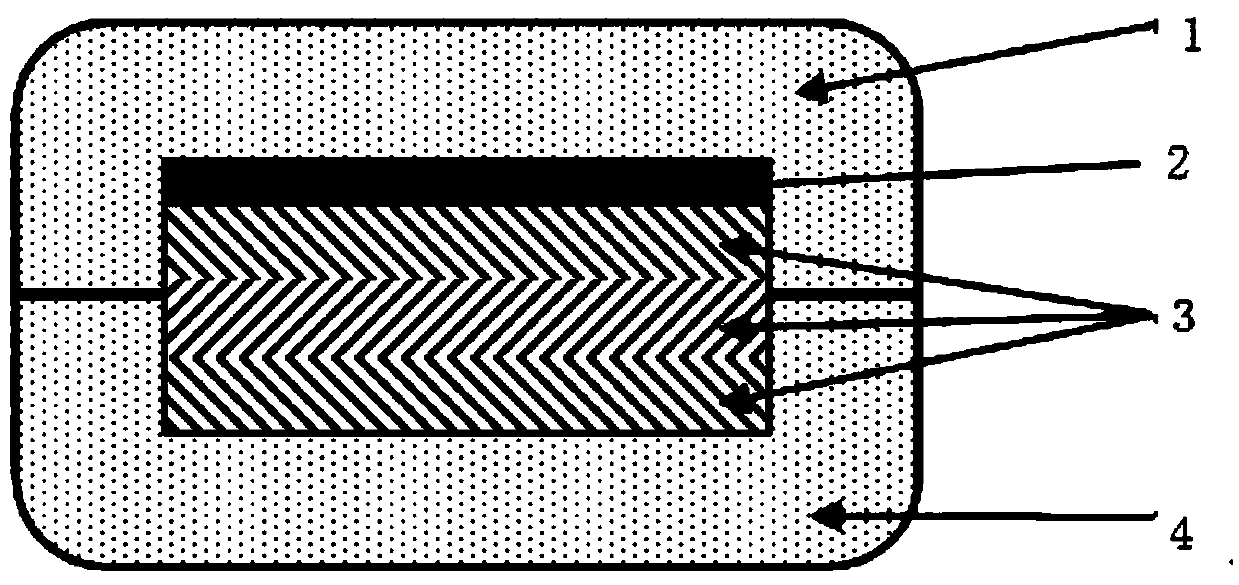

[0034] Try to make a tennis racket by combining a polymer film with a thickness of 0.3mm (from Xiamen Hower New Materials, with a solvent content of 0.1%, a softening point of 80°C, and a curing temperature of 135-145°C) and a fiber composite cloth (curing temperature of 125-135°C). ℃), cut into the required width according to the structure, and then wrap the polymer film on the composite cloth according to the structure, the surface is as figure 1 as shown ( figure 1 It is a schematic diagram of the structure of the single-sided polymer film molding process, wherein 1 is the upper mold, 2 is the polymer film, 3 is multi-layer multi-fiber composite material, 4 is the lower mold), preformed according to the frame shape, and put it into the mold Cavity and close the mold, send it into the hot pressing table with a temperature of 150°C and an external pressure of 100kg / cm 2 , heated for 20min, and then cooled with a cooling plat...

Embodiment 2

[0037] Embodiment 2: 3K woven fabric surface

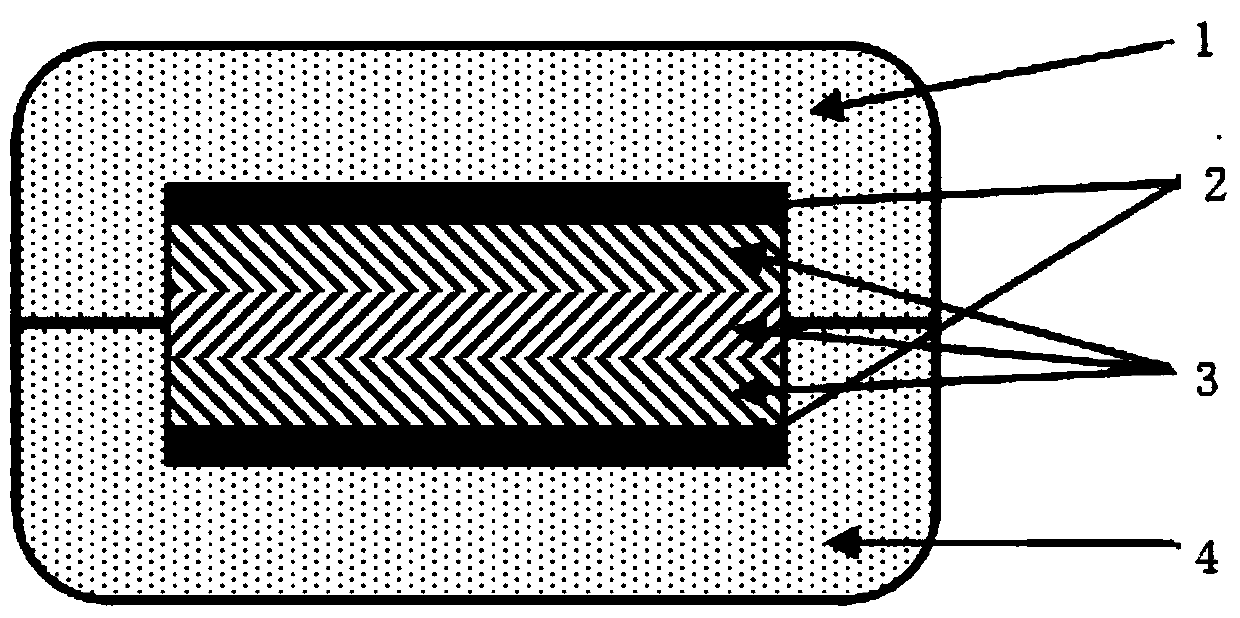

[0038] Try to make a bicycle, cut a polymer film with a thickness of 0.25mm (from Xiamen Haoer New Materials, with a solvent content of 0.2%, a softening point of 75°C, and a curing temperature of 145-160°C) to the desired width according to the structure, and then The structure wraps the polymer film on the outside of the 3K woven fabric (curing temperature 135-145°C), and the surface is as figure 2 as shown ( figure 2 It is a schematic diagram of the structure of the double-sided polymer film molding process, wherein 1 is the upper mold, 2 is the polymer film, 3 is multi-layer multi-fiber composite material, 4 is the lower mold), preformed according to the frame shape, and put it into the mold Cavity and close the mold, send it into the hot pressing table with a temperature of 160°C, and an external pressure of 100kg / cm 2 , heated for 80min, and then cooled with a 30°C cooling platform to an external pressure of 90kg / cm 2 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com