Manufacturing method of static-conducting gauze element used for preventing haze

A production method and a technology for conducting static electricity, applied in the field of anti-haze windows, can solve the problems of poor durability and electrostatic haze repelling effect, poor haze repelling effect of gauze, affecting the conductivity of gauze, etc., so as to improve the antibacterial and bactericidal properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

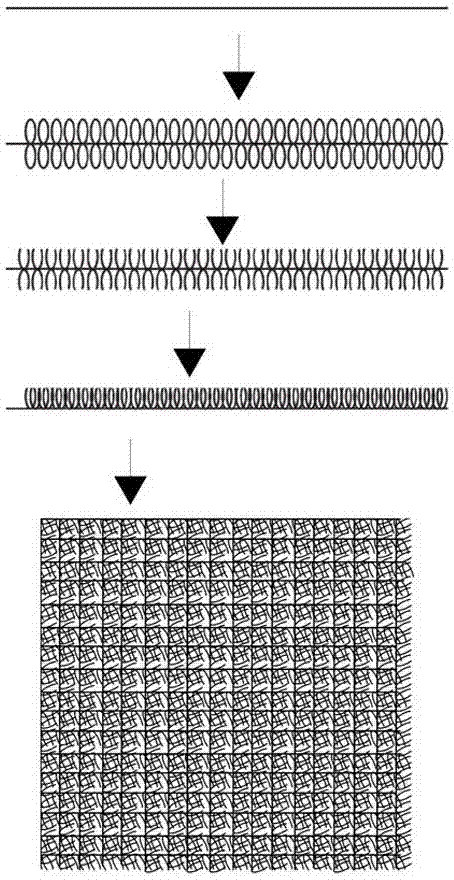

[0022] refer to figure 1 , a kind of preparation method of the antistatic gauze that is used for anti-haze window, wherein: its preparation steps are as follows:

[0023] 1. An ordinary long yarn is used as the main yarn, and then a branch yarn is densely and evenly wound on the main yarn, and the branch yarn is knotted and locked on the main yarn in an "8" shape;

[0024] 2. Cut off the two ends of the "8" prefix of the branch yarn in step 1 to form branch thread fluff, and turn the fluff on one side of the branch thread to the other side, and shape the main yarn and branch thread fluff to form a fluff Cashmere yarn, the length of the branch yarn is controlled within 6mm;

[0025] 3. Use the plush yarn produced in step 2 as the warp and weft threads of the woven gauze for gauze weaving, wherein when weaving the gauze, the branch fluff of the plush yarn should face the same direction to form a plush surface Gauze, the mesh number of the gauze with plush surface is: 5~20 mesh...

Embodiment 2

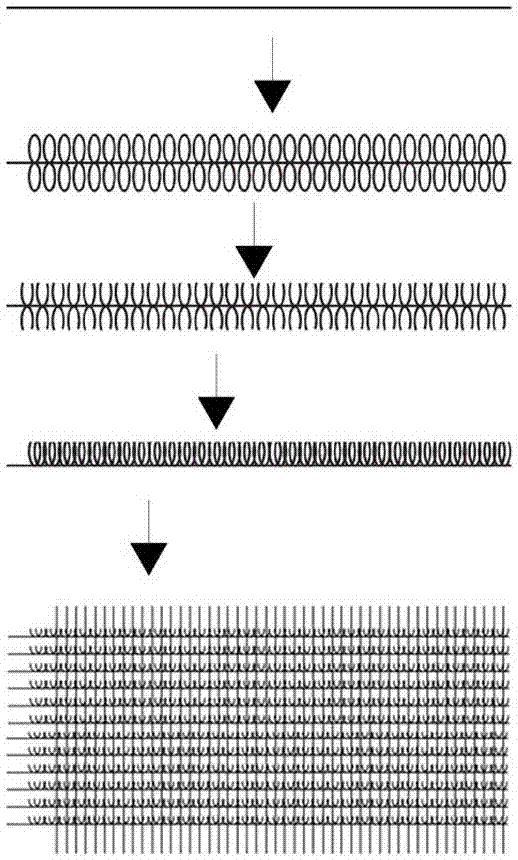

[0029] refer to figure 2 , the only difference from Embodiment 1 is step 3, the plush yarn described in step 2 is used as the warp or weft of the weaving gauze and ordinary yarns are mixed to weave the gauze, and the mesh number of the woven gauze is : 20~50 mesh, using this mixed gauze weaving method, the gauze mesh is not easy to be knotted and drawn, so the mesh mesh of this kind of weaving is relatively dense, and the yield of the gauze mesh is relatively high.

Embodiment 3

[0031] The only difference from Example 1 is step 5. In order to make the static conductive gauze have better oxidation resistance and conductivity, during vacuum sputtering, select a metal target with good conductivity in the vacuum sputtering furnace, first A layer of metal ions with good conductivity, such as silver ions, is sputtered on the gauze coated with a transparent adhesive layer, and then a metal ion with good oxidation resistance, such as nickel ions, is sputtered to make nickel ions with good oxidation resistance Attached to the outermost layer of the transparent adhesive layer, due to the strong passivation ability of metallic nickel, a very thin passivation film can be quickly formed on the surface, which can resist the corrosion of the atmosphere, alkali and certain acids, so it can Provides good oxidation resistance for the static conductive gauze, effectively improving the durability of the static conductive gauze.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com