Indirect sliding friction auxiliary apparatus

A sliding friction and auxiliary device technology, applied in the direction of bearing elements, shafts and bearings, rigid supports of bearing components, etc., can solve problems affecting the operation of the unit, and achieve the effect of solving induration and improving use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

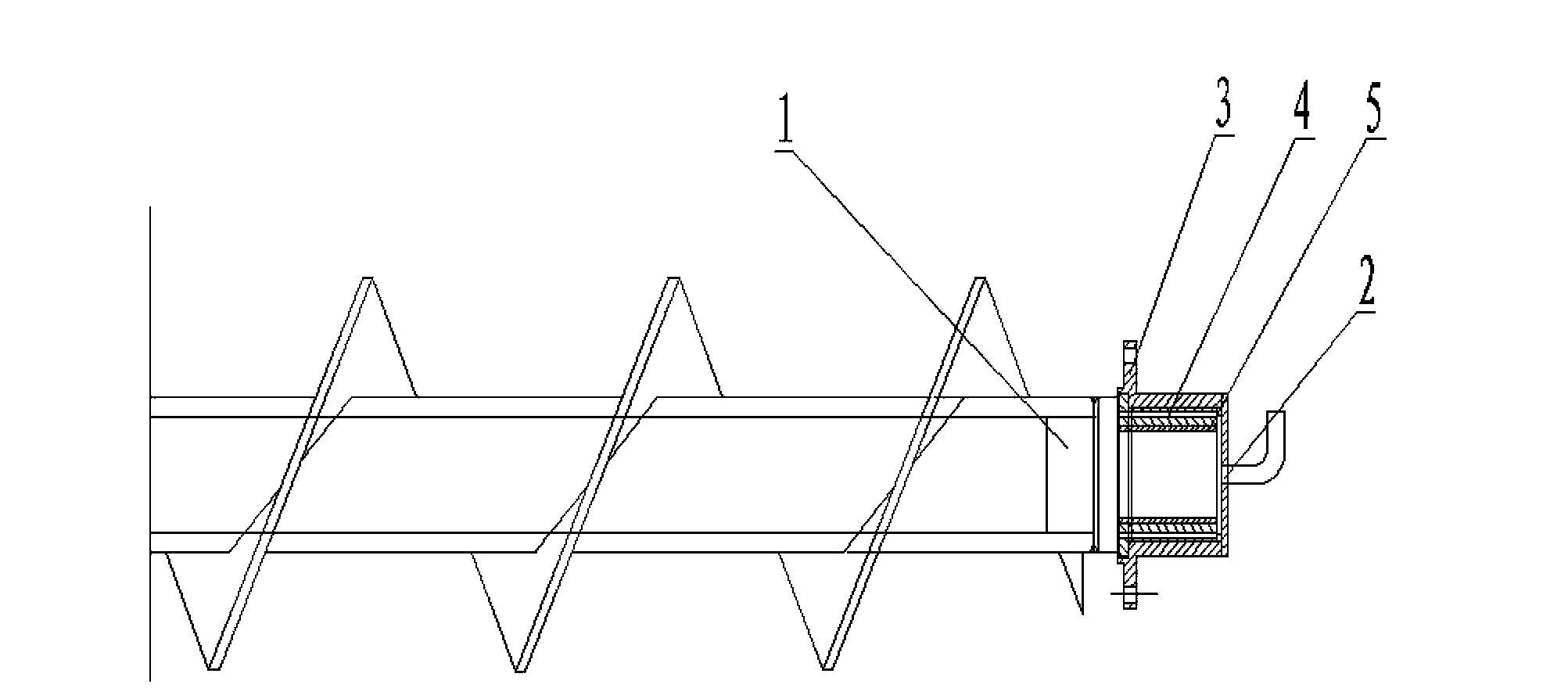

[0009] Such as figure 1 As shown, the indirect sliding friction pair device includes a screw main shaft 1, a lower shaft inner sleeve 5, a lower shaft outer sleeve 4, a lower shaft seat 3, a water-cooled cover 2, the screw main shaft 1 is connected with the lower shaft inner sleeve 5, and the lower shaft inner sleeve 5 is connected with the lower shaft outer sleeve 4, the lower shaft outer sleeve 4 is connected with the lower shaft 3 seat, the lower shaft seat 3 is connected with the water-cooled cover 2, and the lower shaft inner sleeve 5 is a chrome-plated medium-carbon alloy steel processed by precision machining The component is machined with medium carbon alloy steel 40Cr, the outer surface is finished by grinding process, and it needs to be chrome-plated, which enhances the wear resistance, the inner surface is in contact with the screw s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com