Upper locking type damping rail fastener

A technology of fasteners and rails, which is applied in the direction of rails, fixed rails, rail superstructures, etc., can solve the problems of large dynamic displacement of rails, large number of parts, complex structure, etc. The effect of direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

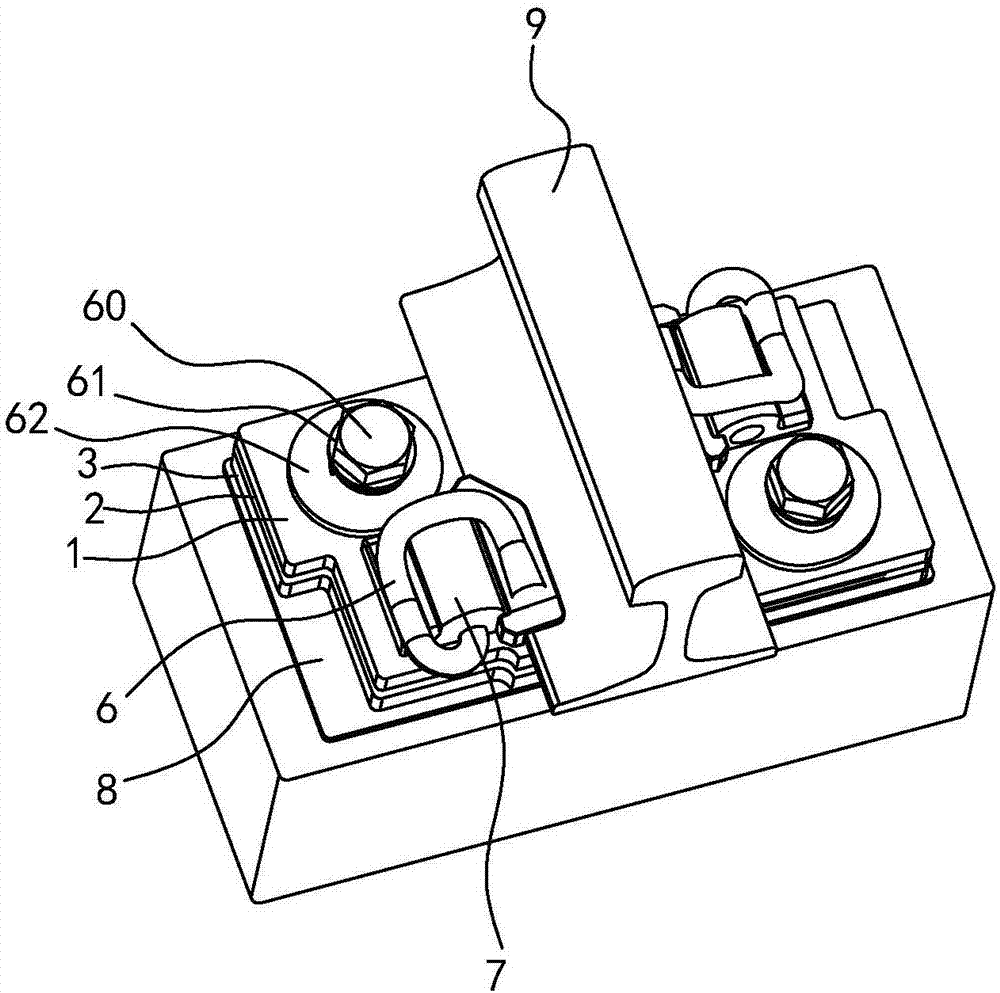

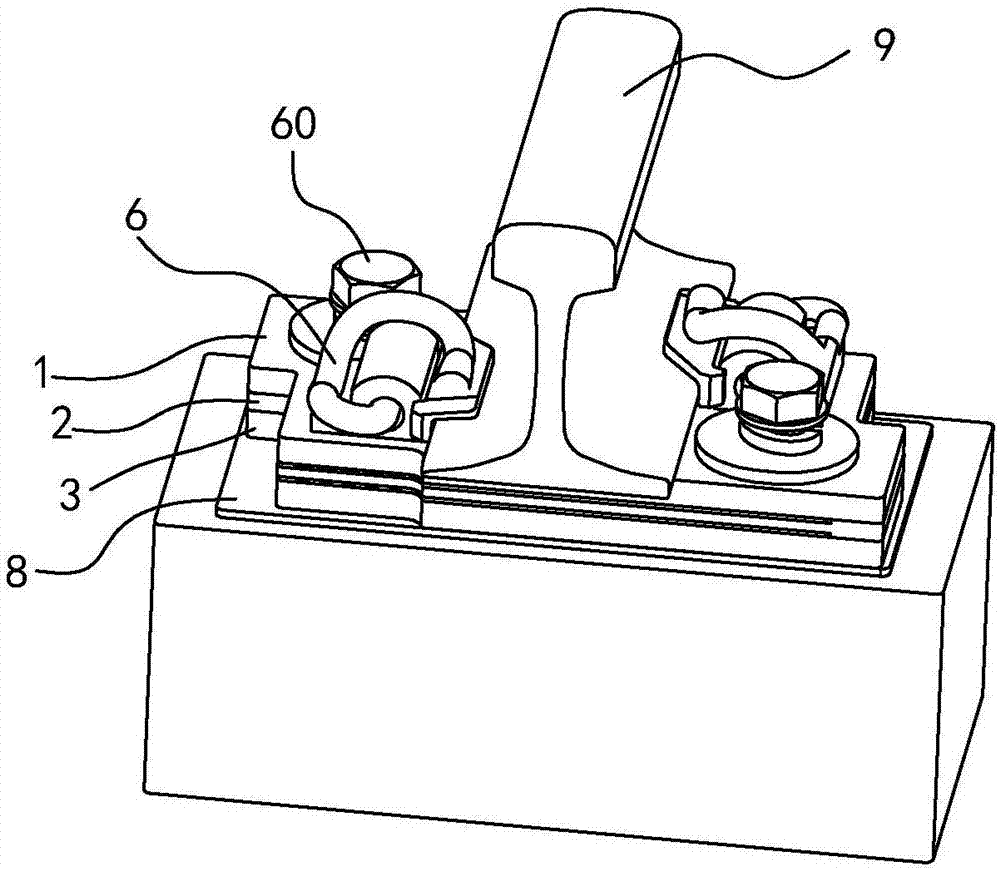

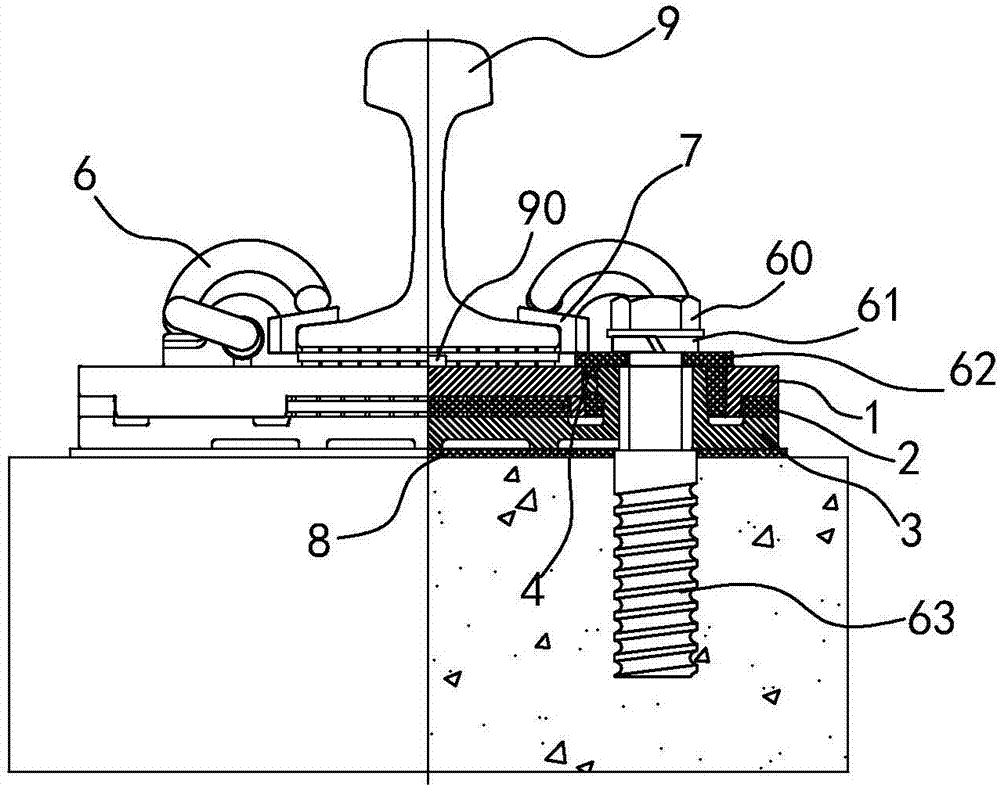

[0052] Example: lock type shock-absorbing rail fasteners

[0053] See attached Figure 1-3 and attached Figure 18 , including insulated buffer backing plate 8 arranged on sleeper 80, iron backing plate combination structure, under-rail backing plate 90, gauge block 7, anchor bolt 60, spring bar 6, spring washer 61, flat pad 62 and pre-set Buried casing 63, rail 9 is pressed on the backing plate 90 under the rail, the backing plate 90 under the rail is located above the iron backing plate combination, two gauge blocks 7 are respectively pressed on both sides of the rail 9, and two spring bars 6 are respectively pressed on the On the two gauge blocks 7 , the anchor bolts 60 pass through the spring washers 61 and the flat pads 62 sequentially and penetrate into the embedded bushings 63 pre-embedded in the sleepers 80 .

[0054] See attached Figure 4-7 , the combined structure of the iron backing plate includes an upper iron backing plate 1, an elastic backing plate 2, a lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com