Energy conservation optimization control method and system for pump station

A technology for optimizing control and control relationship, applied in pump control, liquid displacement machinery, machine/engine, etc., can solve problems such as lack of flexibility and adaptability, different pump wear conditions, and short pump replacement cycle, so as to avoid The effect of frequent start, small overshoot and fast control speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

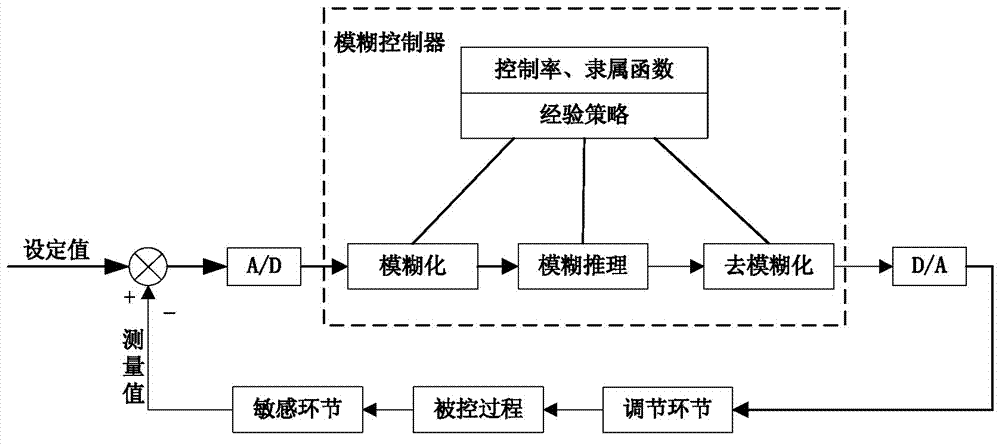

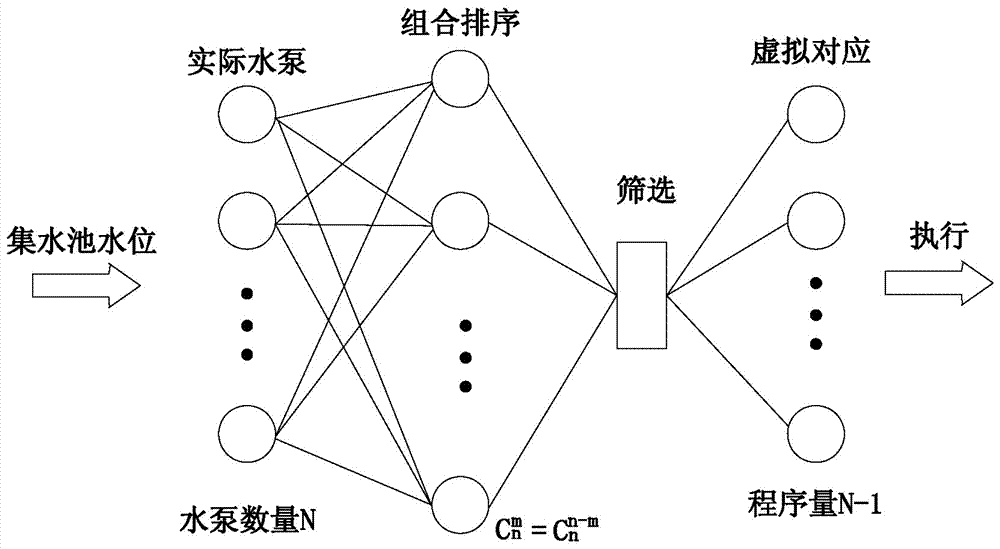

[0027] Such as Figure 4 As shown, the pumping station energy-saving optimization control method of the present invention includes the following steps:

[0028] Step 1. The liquid level difference E, the liquid level change rate EC, and the number U of the pumps to be activated are divided and graded respectively;

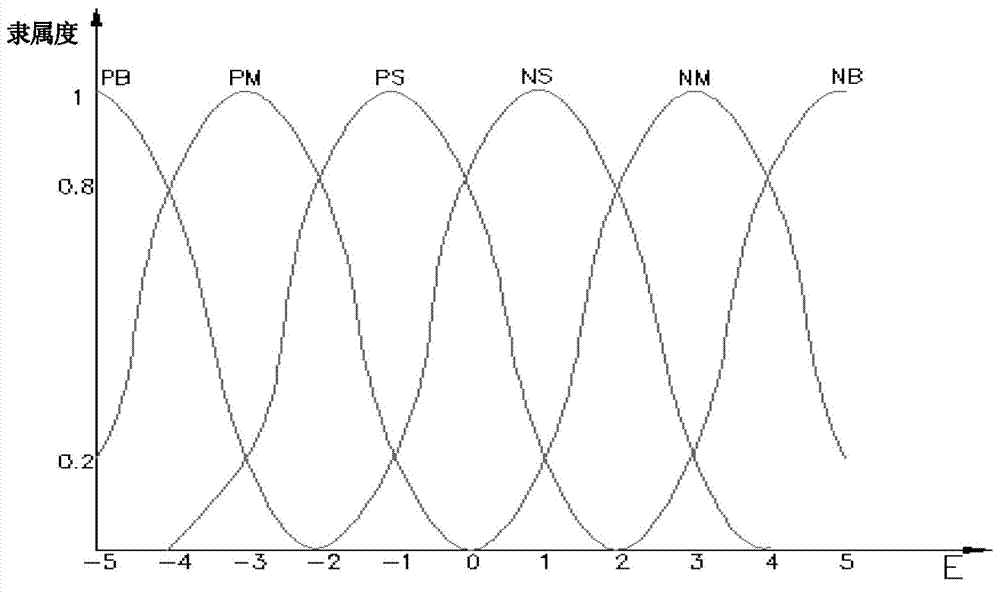

[0029] Step 2. According to the Gaussian function, establish the membership degree table of the gear and series of the liquid level difference E, and set the gear of the liquid level difference E, the gear of the number of starting pumps U, and the gear of the liquid level change rate EC the state table;

[0030] Step 3. According to the membership table and the status table, the weighted average method is used to calculate the control relationship table for the classification of the liquid level difference E, the classification of the liquid level change rate EC and the classification of the number of pumps U;

[0031] Step 4. According to the formula y1=10 / (L2-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com