Compound adjustment pin

A pinning and calibration technology, applied in the field of sight calibration devices, can solve problems affecting observation clarity and aiming accuracy, and achieve the effect of simple structure and fast aiming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

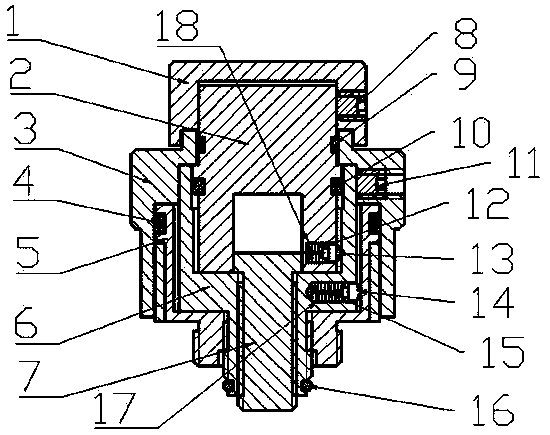

[0012] like figure 1 As shown, it is a compound adjustment nail of the present invention, including a first knob 1, an inner rotation shaft 2, a second knob 3, a fixed body 5, an outer rotation shaft 6, a moving block 7, a screw A8 and a screw B11; The above-mentioned external rotation shaft 6 is arranged on the inner side of the fixed body 5 and is threadedly connected with the fixed body 5; the second knob 3 is arranged on the outside of the fixed body 5, and is connected with the external rotation shaft by a screw B11 The shaft 6 is connected and fixed; the inner rotating shaft 2 is arranged on the inner side of the outer rotating shaft 6; the first knob 1 is arranged on the top of the inner rotating shaft 2, and the screw A8 is connected with the The inner rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com