Mini-tiller easy to drive

A micro-tiller and engine technology, applied in the field of micro-tillers, can solve problems such as low efficiency and high manual labor consumption, and achieve the effects of improving efficiency, simple structure, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

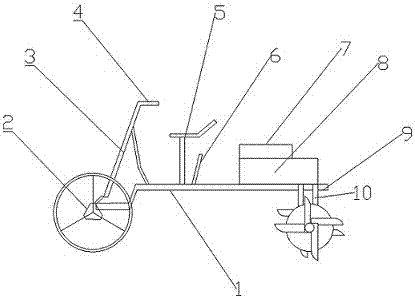

[0032] Such as figure 1 As shown, a micro tillage machine that is convenient for driving includes a micro tillage machine body 1, a front axle 2, a steering wheel 3, a seat 5, an engine 7, a gearbox 8 and a rear axle 9 are arranged on the micro tillage machine body 1, The front axle 2 is installed at the front end of the micro tillage machine body 1, and the front axle 2 is connected with the steering machine 3, a handle 4 is connected to the steering machine 3, a lever 6 is installed at the right rear of the seat 5, the engine 7 and Gear box 8 is installed on the rear of micro tiller body 1, and gear box 8 is installed on the micro tiller body 1, and engine 7 is installed on the top of box 8, and engine 7 is a water-cooled diesel engine, and the bottom of box 8 is connected with Two output shafts 10 are connected to the rear axle 9 .

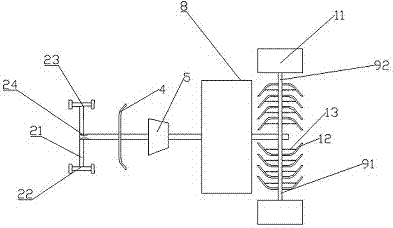

[0033] Such as figure 2As shown, the front axle 2 includes a crossbeam 21, a left bearing sleeve bar 22, a right bearing sleeve bar 23 and ...

Embodiment 2

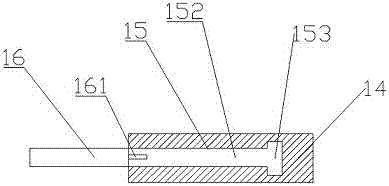

[0037] The difference from Example 1 is that, as Figure 6 As shown, an opening 111 is provided on the tire 11, and a sealing cover 112 used in conjunction with the opening 111 is arranged on the opening 111. The rotary tiller 12 includes a mounting seat 121 and a rotary tiller blade 122, and the rotary tiller blade 122 is made of high manganese and high carbon. Made of steel material. Such as Figure 7 As shown, the top of the second mounting rod 16 is provided with a U-shaped groove 162, and the tire 11 mounted on the second mounting rod 16 is a rubber tire.

[0038] When the tiller is going to cultivate the land, the sealing cover on the tire 11 is opened 112, all the gas inside the tire 11 is released, then the tire 11 is folded and placed in the U-shaped groove 162, and the second mounting rod 16 is placed along the Groove 151 advances in the first installation rod 14, then rotates the second installation rod 16, the second installation rod 16 and tire 11 are fixed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com