One-piece forming mechanism for transplanting seedlings, making nests and forming holes

A technology for seedling transplanting and forming mechanism, which is applied in the fields of excavation/covering of trenches, agriculture, and applications, can solve the problems of high labor intensity, time-consuming and labor-intensive, low production efficiency, etc. Guaranteed growth quality and survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

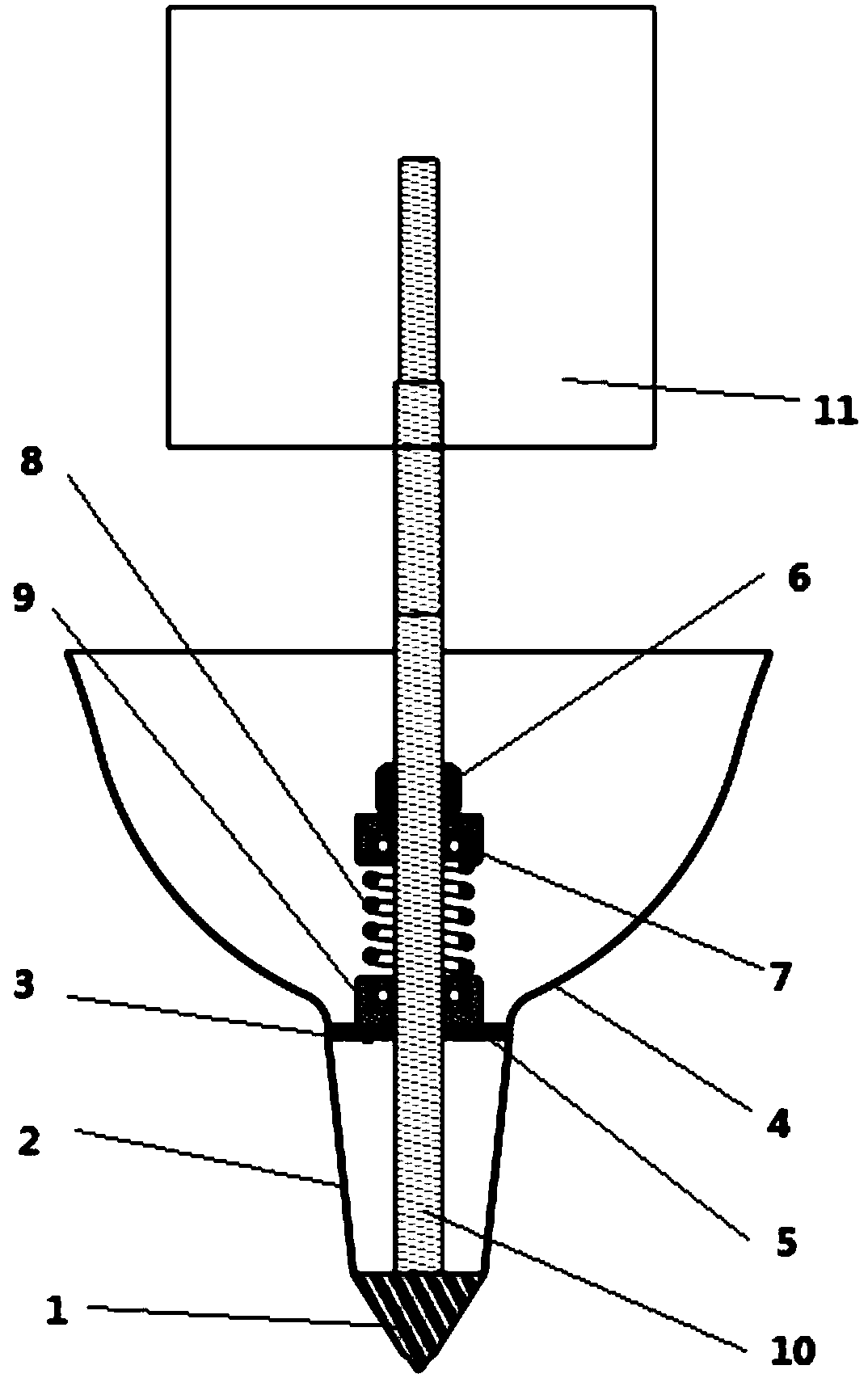

[0018] Such as figure 1 As shown, a seedling transplanting, nesting, and hole-forming integrated mechanism in this embodiment includes a rotating hole opening mechanism, which is composed of a drilling bit 1 and a rotating cone sleeve 2; the drilling bit 1 is connected with a rotating shaft 10 The vibration and rotation power source 11 is connected; the rotating taper sleeve 2 is set outside the rotary shaft 10, and is fixedly connected with the rear end of the drilling bit 1; Disk 3; vibrating rammed earth mechanism, set outside the rotary shaft 10, corresponding to the upper and lower sides of the rotating cone sleeve 2, composed of a rammed earth cylinder 4 and a loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com