A large-cavity-sleeve deep-hole integrated molding method and device for seedling transplanting

A technology for seedling transplanting and forming device, applied in the directions of planting method, application, excavation/covering of trenches, etc., can solve problems such as the influence of seedling growth and development quality, and achieve the effect of ensuring growth quality and survival rate, and ensuring upright growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

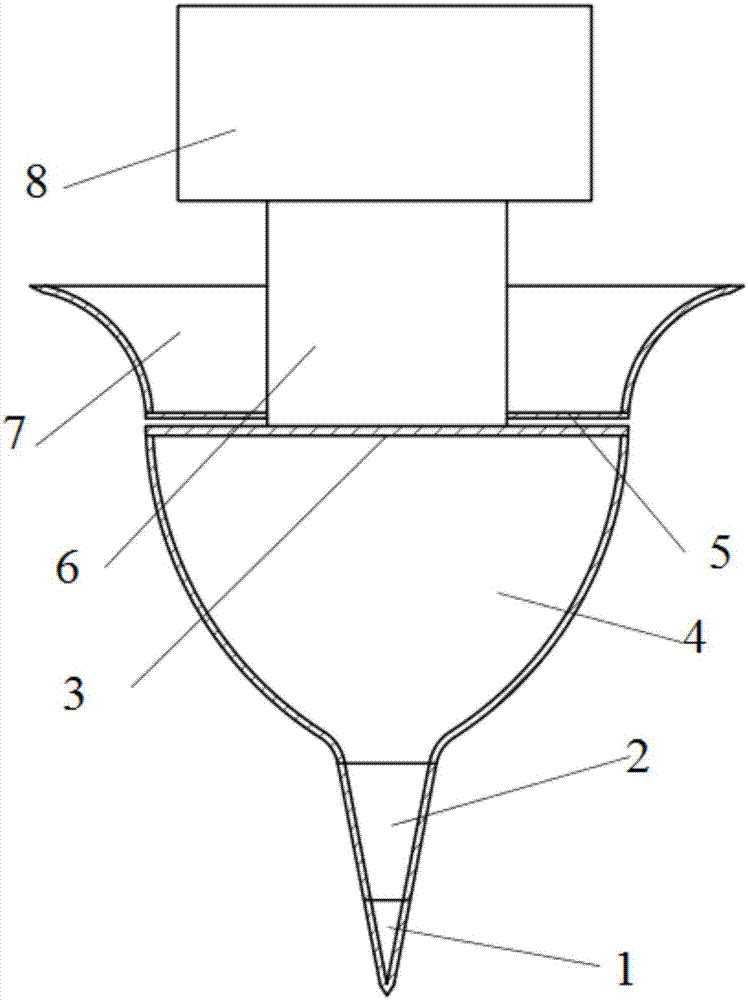

[0036] Such as figure 1 As shown, a large nest cover deep hole integral molding device for transplanting and making nests of seedlings in this embodiment is used to realize the above method. Cover 2, large dimple forming die 4, the perforating drill bit 1 is connected with the vibration and rotation power source 8 through the power connection device 6; the rotating cone sleeve 2, large dimple forming die 4 are all set outside the power connection device 6, And one end of the rotating cone sleeve 2 is affixed to the rear end of the perforating drill bit 1, and the other end is connected with the large dimple forming die 4 to form an integral body. The rotating cone sleeve 2 and the large dimple forming die 4 are an integral structure. The outer wall of the large dimple forming die 4 has a bowl-shaped linear profile, and its mouth is far away from the rotating taper sleeve 2; that is, the small end of the rotating taper sleeve is connected with the drilling bit, and its large en...

Embodiment 2

[0041] Such as figure 1As shown, the difference between the present embodiment and the first embodiment is that the forming device further includes a topsoil anti-collapse plate 7 that is rotatably connected with the large cavity forming die 4 through a movable assembly. The surface soil anti-collapse plate 7 is plate-shaped, and the diameter of the small end of the surface soil anti-collapse plate 7 is greater than or equal to the diameter of the large end of the large dimple forming mold 4. Between the mold 4, the said swivel can adopt rubber ring, also can adopt slewing bearing.

[0042] During work, at first the power connection device 6 needs to be fixed on the vibrating and rotating power source 8, and then the friction force of the rubber ring provided between the surface soil anti-collapse plate 7 and the large dimple forming mold 4 is used to ensure the surface soil anti-collapse plate 7 and the large cavity forming plate. The nest forming mold 4 can be rotated toget...

Embodiment 3

[0045] Such as figure 1 As shown, the difference between the present embodiment and the second embodiment is that the structure of the movable assembly is different, it includes the lower friction disc 3, the upper friction disc 5 and the locking device, and the large dimple forming die 4 is away from the punching hole One end of the drill bit 1 is provided with the lower friction disc 3, and the end of the topsoil anti-collapse disc 7 facing the large dimple forming die 4 is provided with the upper friction disc 4 which is in frictional contact with the lower friction disc 3 , the locking device is located in the surface soil anti-collapse plate 7 and is located on the power connection device 6; by the perforating drill bit 1, the rotating cone sleeve 2, the large dimple forming die 4, the lower friction disc 3, the power connection device 6, the vibration The rotating power source 8 constitutes a rotating opening mechanism; the surface soil anti-collapse plate 7, the upper f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com