Heater unit for equipment for heating and/or frothing milk

A foaming milk and heater technology, applied in applications, kitchen utensils, home utensils, etc., can solve the problems of narrowing radial channels, time-consuming, troublesome removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

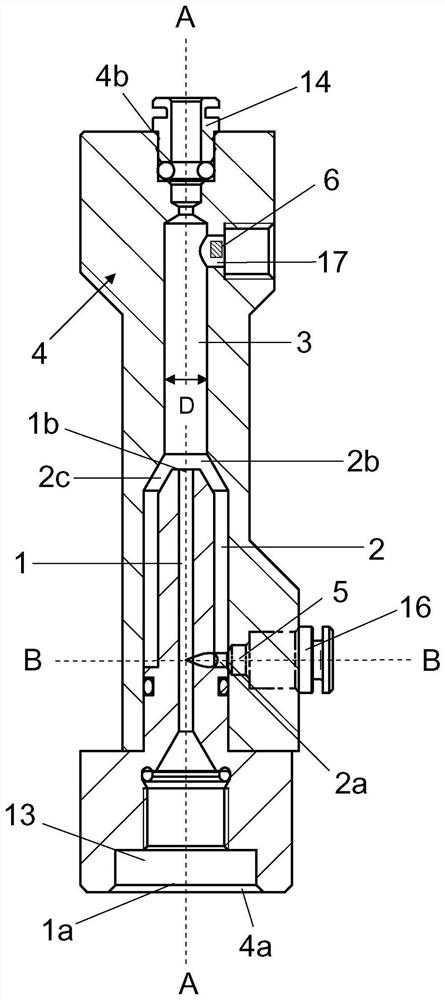

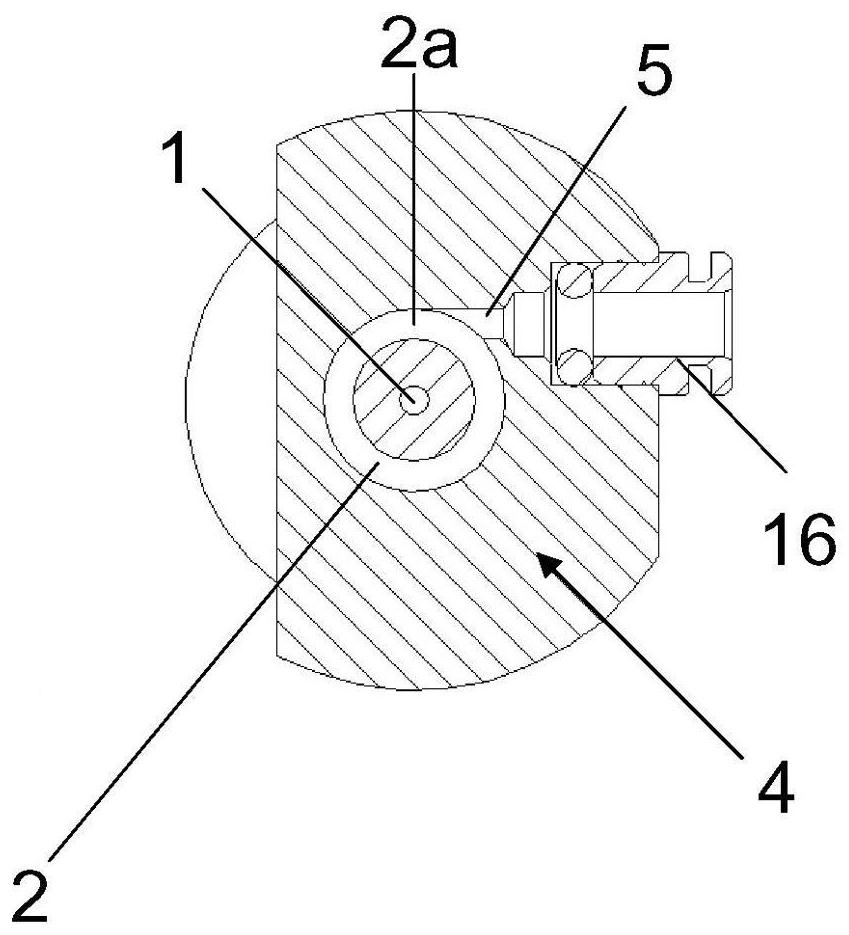

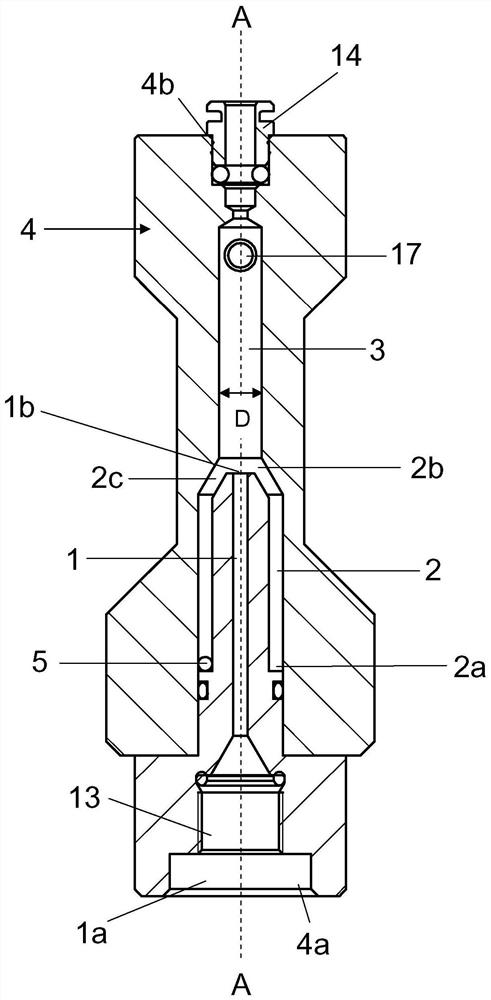

[0024] exist Figure 1-3The heater unit according to the invention shown in , comprises a reaction block 4 made of plastic, in particular PEEK, PSU or PEI, which essentially has the shape of a cylinder with a central longitudinal axis A. An inner steam channel 1 , an outer annular channel 2 coaxially surrounding the inner steam channel 1 , and an outlet channel 3 arranged coaxially to the steam channel 1 are formed in the reaction block 4 . The steam channel 1 has an upstream end 1 a which is formed by an end-side opening 4 a in the reaction block 4 . Furthermore, the inner steam channel 1 has a downstream end 1 b which opens into an outlet channel 3 extending coaxially on the steam channel 1 in the direction of flow. The outlet channel 3 ends at an end-side opening 4 b in the reaction block 4 . In this case, the diameter of the outlet channel 3 is larger than the diameter of the steam channel 1 , for example twice as large. The outer annular channel 2 is arranged coaxially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com