Water heater having automatic filtration core washing function, and control method thereof

An automatic cleaning and water heater technology, which is applied to chemical instruments and methods, separation methods, membrane filters, etc., can solve the problems of automatic cleaning of the filter element usage status and inability to accurately detect and judge the usage status of the filter element, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment is an embodiment of the basic structure of the present invention, which can realize the judgment of the use of the filter element and realize cleaning, but the cleaning process requires manual control of the valve, and the degree of automation is not high.

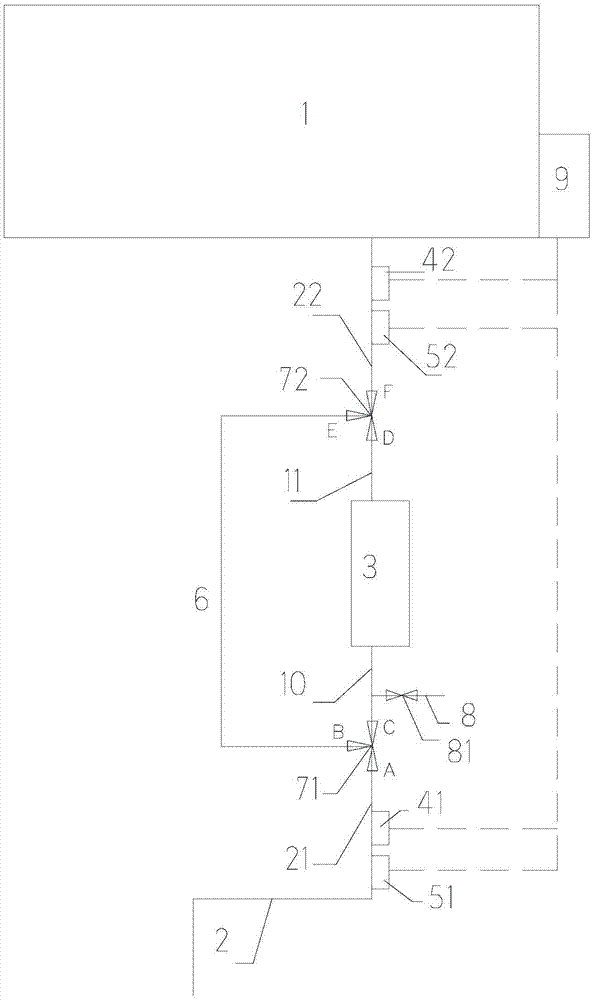

[0036] Such as figure 1 , a water heater with the function of reminding and cleaning the filter element, comprising a water heater body 1, a controller 9 is arranged on the water heater body 1, a filter element 3 is arranged on the water inlet pipe 2 of the water heater body 1, and the water inlet pipe is located between the water inlet of the filter element. The side is the water inlet section 21, and the side of the water outlet of the filter element is the water outlet section 22. The water inlet section 21 is provided with a water inlet section pressure sensor 41 and a water inlet section flow sensor 51 connected to the controller 9. The water outlet section The section is provided with a water o...

Embodiment 2

[0047] This embodiment is an optimization based on the first embodiment, and the pipeline layout and valve positions are evenly changed, but the three-way valve and the sewage valve are electric valves and connected to the controller, and the controller adds a cleaning module, etc. It can realize the automatic completion of detection and cleaning.

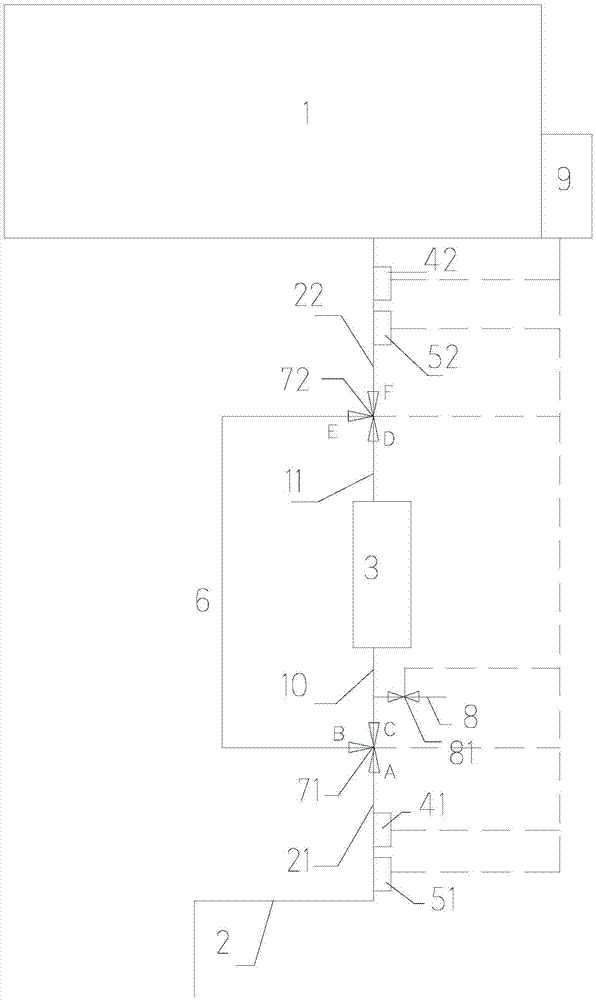

[0048] Such as figure 2 , since the pipeline structure and valve position are the same as those in Embodiment 1, the same parts will not be repeated here. It only describes the connection relationship between the three-way valve 71 of the water inlet section, the three-way valve 72 of the water outlet section and the drain valve 81 and the controller 9 , and the module structure of the controller 9 .

[0049] specific as Figure 4 , the controller 9 includes a reminder module 92 and a cleaning module 93 connected to the CPU91. The three-way valve 71 of the water inlet section, the three-way valve 72 of the water outlet section ...

Embodiment 3

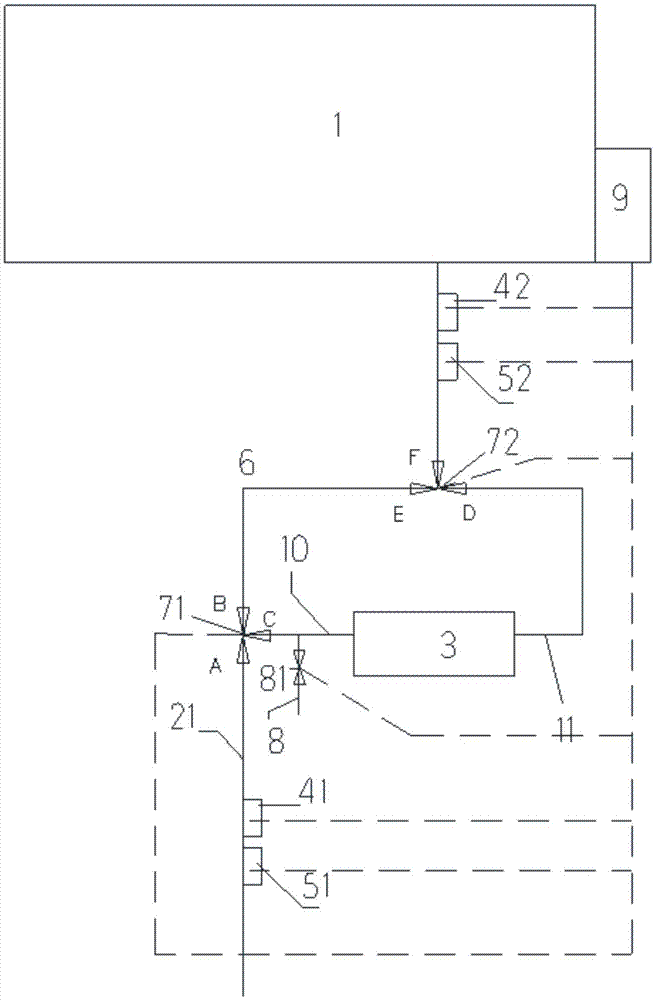

[0053] This embodiment is a further optimization of embodiment two, such as image 3 , this embodiment is to change the pipeline arrangement of the second embodiment, shortening the length occupied by the filter element under the water heater. It is conducive to installation, reduces the occupation of toilet space, and is convenient for users to use. This embodiment is a preferred embodiment of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com