Drilling machine structure with convenience in use

A drilling machine, a convenient technology, applied in the direction of boring/drilling, drilling/drilling equipment, parts of boring machine/drilling machine, etc. The speed of force transfer is difficult to control and other problems, so as to avoid space limitation, facilitate and efficient operation, and avoid difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

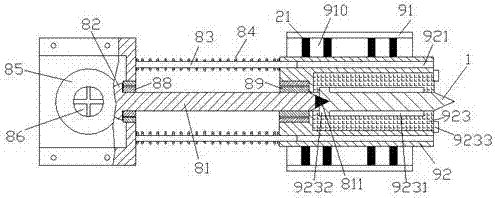

[0011] Combine below Figure 1-4 The present invention will be described in detail.

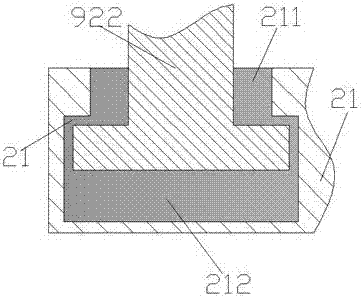

[0012] An easy-to-use drilling machine structure according to an embodiment of the present invention, used for drilling from a side direction relative to the direction the user is facing, includes a fixing member (9) and a turning-in member (8), Wherein, the fixed member includes a fixed seat (91) and a drill bit storage part (92), and the bottom of the drill bit storage part (92) is provided with a sliding foot piece (922) for connecting with the drill bit storage part (92). The rubber pad (21) in the sliding groove (910) of the fixed seat (91) is engaged, and the rubber pad (21) includes two sides of the sliding foot (922) to support the sliding The spring joint clamping part (211) clamped and fixed by the connecting foot piece (922) and the spring joint located on the bottom side of the sliding foot piece (922) to allow adjustment of the upper and lower positions of the sliding foot piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com