Digital display grinding device for high-temperature high-pressure steam valve sealing surface

A valve sealing, high temperature and high pressure technology, which is applied in the direction of grinding devices, grinding machine tools, metal processing equipment, etc., can solve the problems of low efficiency, uncontrolled work flow, and inability to fully guarantee the grinding accuracy, and achieve good stability and high grinding accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

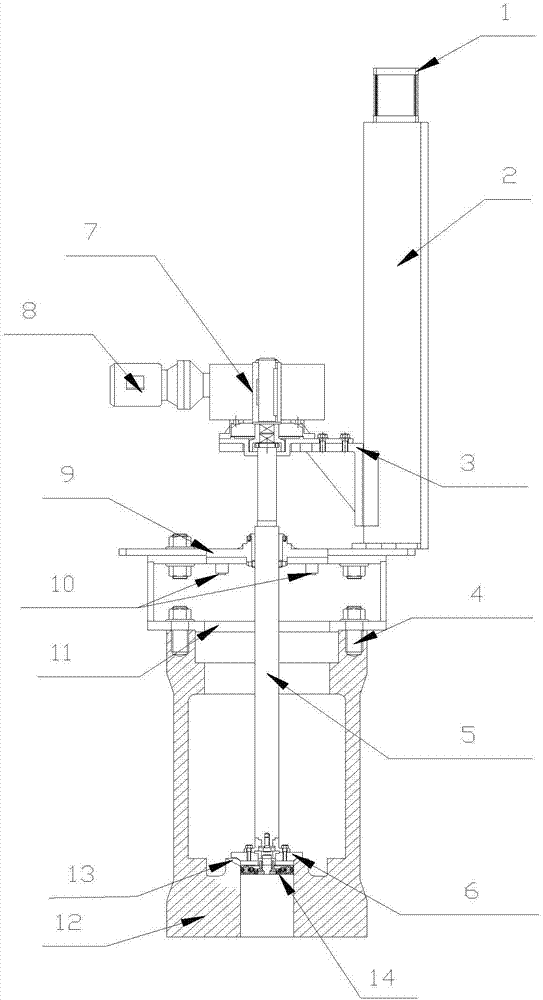

[0015] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

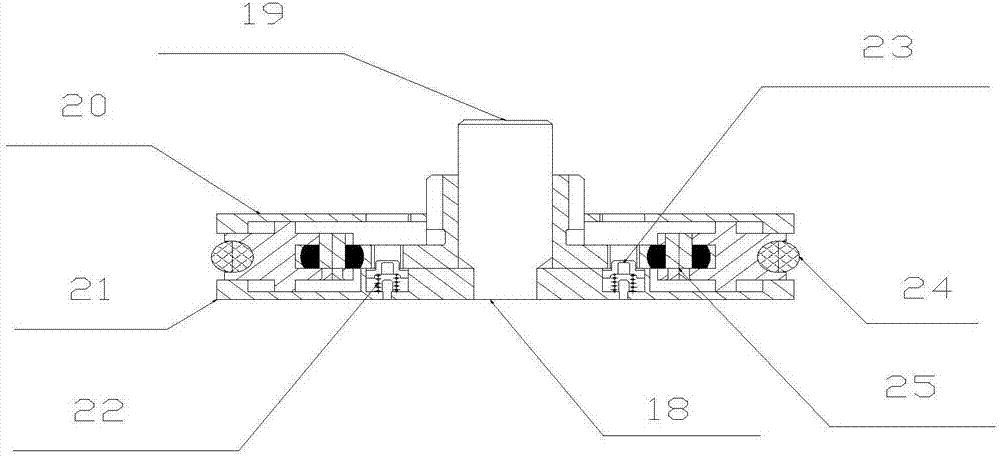

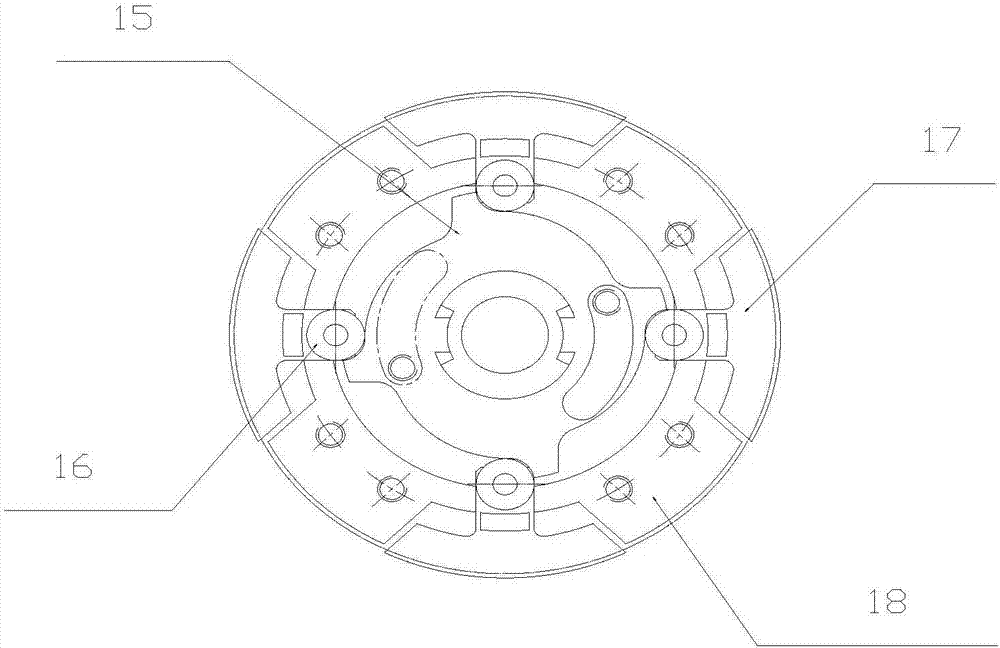

[0016] Such as figure 1 As shown, the digital display grinding device for the sealing surface of high-temperature and high-pressure steam valves of the present invention includes a stepping motor 1, a lifter 2, a lifting platform 3, a first fixing bolt 4, a main shaft 5, a grinding disc 6, a turbine box 7, a grinding Motor 8, support upper plate 9, camera 10, support lower plate 11, valve body 12, overlay welding layer 13, tensioning device 14, stepping motor 1 is connected with lifter 2, lifting platform 3, support upper plate 9 are all connected with Lifter 2 is connected, and lifting platform 3 is positioned at the top of support upper plate 9, and lifting platform 3 is connected with turbine box 7, and turbine box 7 is connected with grinding motor 8, and multiple cameras 10 are inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com