Combining method for splicing box culvert single cabins into multi-cabin body

A combination method and technology of box culverts, applied in the field of combination of single cabin and multiple cabins of box culvert, can solve problems such as damage and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

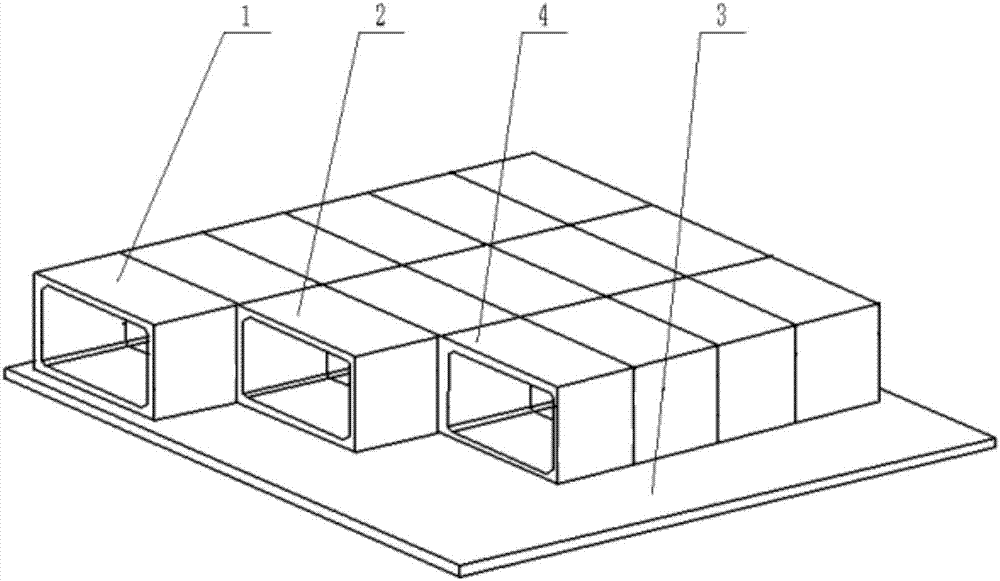

[0019] Example one, according to the attached figure 1 :

[0020] The combination method of single cabin and multiple cabins of box culvert includes the following steps,

[0021] Step 1: Lay concrete bottom plate 3 on the foundation;

[0022] Step 2: On the concrete bottom plate 3, connect them to form No. 1 culvert tank 1 through box culverts;

[0023] Step 3: On the concrete bottom plate 3, the second culvert tank 2 is connected to each other through box culverts, and the second culvert tank 2 is placed on the right side of the first culvert tank 1;

[0024] Step 4: On the right side of No. 2 culvert tank 2, the No. 3 culvert tank 4 connected to each other by box culverts is attached to it.

[0025] The connection modes between the No. 1 culvert 1, No. 2 culvert 2 and No. 3 culvert 4 are the same. The second culvert 2, the first culvert 1 and the third culvert 4 are provided with a modified asphalt waterproof layer.

Embodiment 2

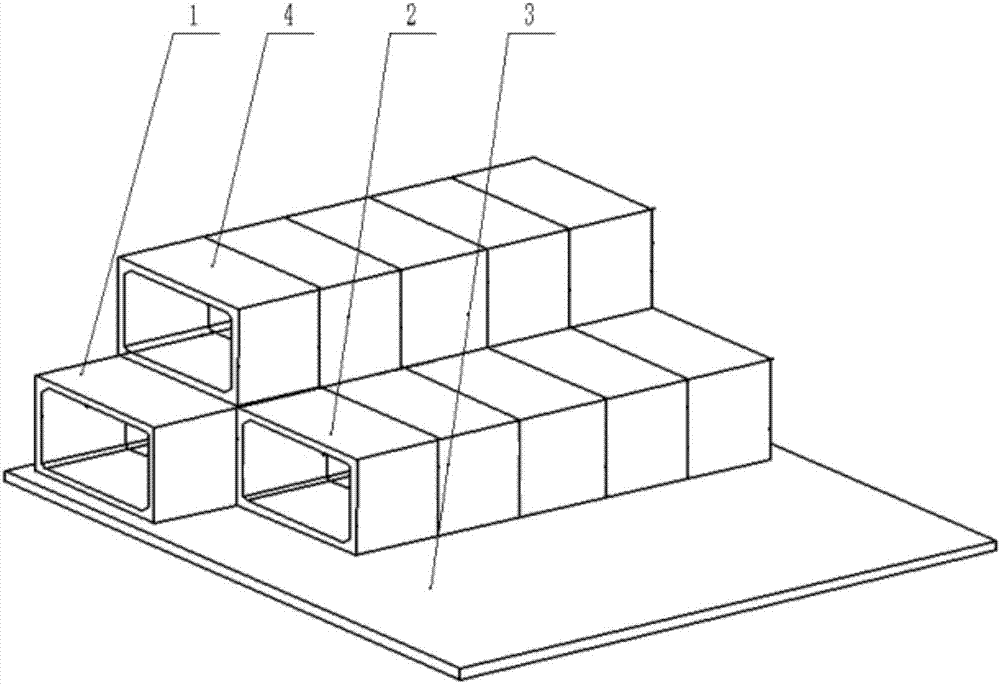

[0026] Example two, according to the attached figure 2 :

[0027] The combination method of single cabin and multiple cabins of box culvert includes the following steps,

[0028] Step 1: Lay concrete bottom plate 3 on the foundation;

[0029] Step 2: On the concrete bottom plate 3, connect them to form No. 1 culvert tank 1 through box culverts;

[0030] Step 3: On the concrete bottom plate 3, the second culvert tank 2 is connected to each other through box culverts, and the second culvert tank 2 is placed on the right side of the first culvert tank 1;

[0031] Step 4. The No. 1 culvert tank 1 is directly above the No. 3 culvert tank 4 connected to each other by box culverts.

[0032] The connection modes between the No. 1 culvert 1, No. 2 culvert 2 and No. 3 culvert 4 are the same. The second culvert 2, the first culvert 1 and the third culvert 4 are provided with a modified asphalt waterproof layer.

Embodiment 3

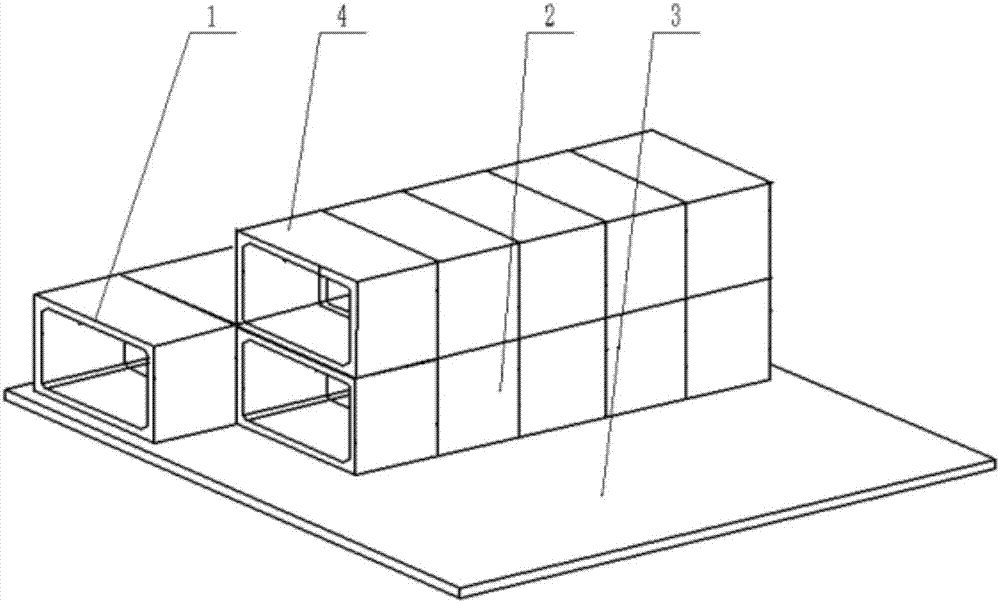

[0033] Embodiment three, according to the attached image 3 :

[0034] The combination method of single cabin and multiple cabins of box culvert includes the following steps,

[0035] Step 1: Lay concrete bottom plate 3 on the foundation;

[0036] Step 2: On the concrete bottom plate 3, connect them to form No. 1 culvert tank 1 through box culverts;

[0037] Step 3: On the concrete bottom plate 3, the second culvert tank 2 is connected to each other through box culverts, and the second culvert tank 2 is placed on the right side of the first culvert tank 1;

[0038] Step 4. The No. 2 culvert tank 2 is directly above the No. 3 culvert tank 4 connected to each other by the box culvert.

[0039] The connection modes between the No. 1 culvert 1, No. 2 culvert 2 and No. 3 culvert 4 are the same. The second culvert 2, the first culvert 1 and the third culvert 4 are provided with a modified asphalt waterproof layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com